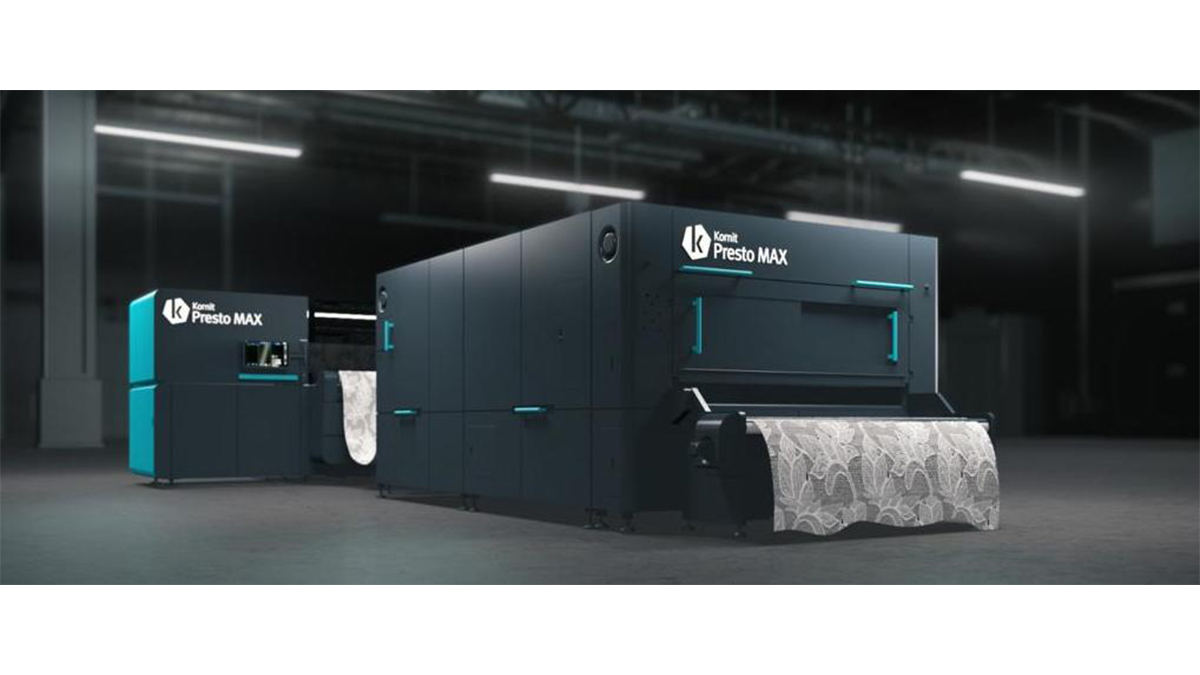

Kornit Digital, one of the leading brands in advanced digital printing solutions, announced that they have launched the Kornit Presto MAX system for sustainable on-demand production of apparel and other textile goods. Presto MAX, the first digital printing system to offer white printing on coloured fabrics, was first introduced live at Kornit Fashion Week Los Angeles + Industry 4.0 Event held on November 2-5. Introduced as the single-step solution for direct-to-garment printing and the most sustainable solution available, the new system delivers the highest quality and softest feel, with brilliant whites and brighter neon colours. The system is ready to incorporate future iterations and evolutions of XDi technology; 3D decorative applications to produce threadless embroidery, high-density, vinyl, screen transfer, and other innovative effects.

“Kornit Presto MAX is breaking the barriers between imagination and physical applications”

Kornit Digital Chief Executive Officer Ronen Samuel said that Presto said that MAX is breaking barriers between imagination and physical applications by transforming digital into the catalyst for modernizing the business. Stating that this will change the textile industry forever by connecting consumers and fulfillers on a global scale and truly capitalizing on digital’s promise for delivering both sustainability and profitability, free of waste, Samuel said the followings:

“Whether your business is finished goods or ready-to-use custom fabrics, growing your own brand or supplying the world’s retailers and entrepreneurs, this technology represents the cutting edge of on-demand, unconstrained textile production, in terms of both capability, accessibility, and sustainability. Kornit empowers producers to create more with less, shrink their carbon footprint, and deliver unlimited expression while creating new opportunities and growth”.

Production anytime, anywhere

Compatible with natural fabrics, synthetic fabrics and blends, Kornit Presto MAX includes advanced algorithms for smart autonomous calibration to deliver high-quality results with short cycle times and minimal manual interruptions or defects. In addition, the system supports a truly distributed production model that fulfils nearer the end consumer and is designed for compatibility with the KornitX global fulfilment ecosystem to enable production anywhere, anytime, while empowering brands to ensure quality and consistency across all systems and production sites, as well as eliminating time and logistical waste from the experience.