Vandewiele participated at Domotex 2018 exhibition in Hannover and exhibited its solutions. The company offers its customers complete carpet solutions, from granulate to carpet. The portfolio contains BCF extrusion lines, heat-setting machines, tufting machines and carpet weaving machines. The synergy of competences in these different fields leads not only to important technical breakthroughs, but is mainly in the benefit of the customer.

The DOMOTEX fair is for Vandewiele the opportunity to meet all present customers and many prospects for future business. Of course, it is important to participate to show the presence in the market, but it also is the opportunity to strengthen the long-term relationship with them customers. And it’s the perfect platform to present Vandewiele’s latest developments and products to the carpet industry.

Vandewiele, expert in yarns

The quality of a carpet starts with the quality of the yarns. Therefore, Van de Wiele offers its customers BCF extrusion lines. The experience in woven and tufted carpet, combined with the knowledge of yarn production, has led to the development of performant extrusion lines.

After extrusion, the yarns can be heat-set. The French company Superba, part of Vandewiele, has been the world-leading manufacturer of heat-setting lines for many years. Superba has developed a unique and performing heat-setting system based on saturated steam, suitable for polypropylene, polyamide, acrylic, wool…. The space-dyeing machine, which allows applying a pattern of colors on yarns, is already an incredible success. It allows making new woven and tufted carpet qualities. And the success story continues with the solid color dyeing on acrylic yarns. Flexibility in volume, time and a quite low energy cost increase possibilities for the handlook carpets.

Van de Wiele, expert in weaving

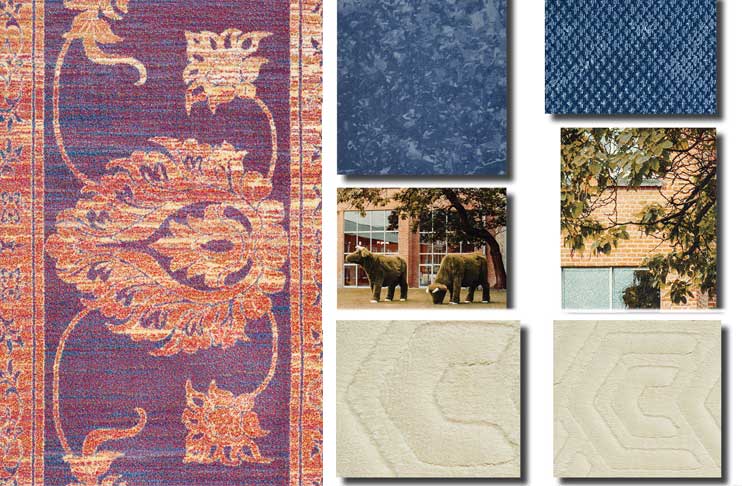

The HCiX2 Handlook Carpet Innovator is a high density carpet weaving machine using the patented three rapier weaving technique with stationary incorporated pile yarns, giving a clear back, less incorporation and a higher weaving efficiency. The design on the pile side is crystal sharp. There are no visible warp yarns on the backside, which makes the carpet look like real handknotted.

With the HCiX2 carpets in acrylic, viscose, polyester,… are woven with optimized efficiency. Designs in the border, filling effects and natural fringes are all possible. Them newly developed handlook carpet weaving machine has a reed density of 1500 d/m in 8 pile frames. With this execution of the HCiX2, carpet qualities up to 5.000.000 pile points per square meter can be reached!

Van de Wiele, expert in tufting

Together with Cobble, Van de Wiele has developed the Myriad. “Myriad” is the Greek word for an indefinitely large number of things and describes perfectly the possibilities of this machine. Each pile yarn goes over a separate roll, controlled by an individual servomotor, and this over the complete width of the machine without any repeat. With this technology patterns are created in the carpet.

The newly developed Myriad 1/12” makes it possible to tuft any picture in High resolution. Extremely big designs of 14m by 17m are now possible to produce thanks to newly developed software. This is very suitable for wall-to-wall carpets in the contract market.

Colortec

With the Colortec and its ICN system, the individual control needle, a higher efficiency and quality will be reached. Moreover, this allows you to tuft with “weaker” yarns (e.g. wool), less yarn on the back and this up to 9 colors.

The Colortec can be combined with an IPD system for active yarn feed. This allows for much better pile control, resulting in a cleaner surface of the fabric.

To reduce energy consumption, all tufting and carpet weaving machines of Vandewiele are equipped with an energy bus. This energy bus distributes the energy between the different motors that need or supply power.

They announced the launching of the fully redesigned, mobile-responsive website of our Van de Wiele brand; www.vandewiele.be