From fiber to fabric, Uster Technologies is recognized as one of the world’s leading providers of quality management solutions. As a trusted partner, the company offers textile manufacturers the ideal mix of open communication inside the factory and complete confidentiality to the outside. Helping manufacturers maximize the commercial value of their investments, Uster also provides expert guidance to manufacturers on how best to integrate their systems into the production and processing environment. Uster Technologies offers a two-way approach for quality assurance in nonwovens concerning fabric inspection.

The company’s portfolio includes quality management, laboratory testing, and in-line process control instruments for fibers, staple fibers, filament yarns, fabrics, and nonwovens. With its “Think Quality” approach, Uster Technologies provides safe solutions for nonwovens manufacturers. Where quality is essential and contamination is unacceptable, the Uster contamination sorter offers the industry a safer way to deal with contamination. In this regard, Uster Technologies points out a two-way approach for quality assurance in nonwovens concerning fabric inspection.

Uster contamination sorter presents a technology that detects defects

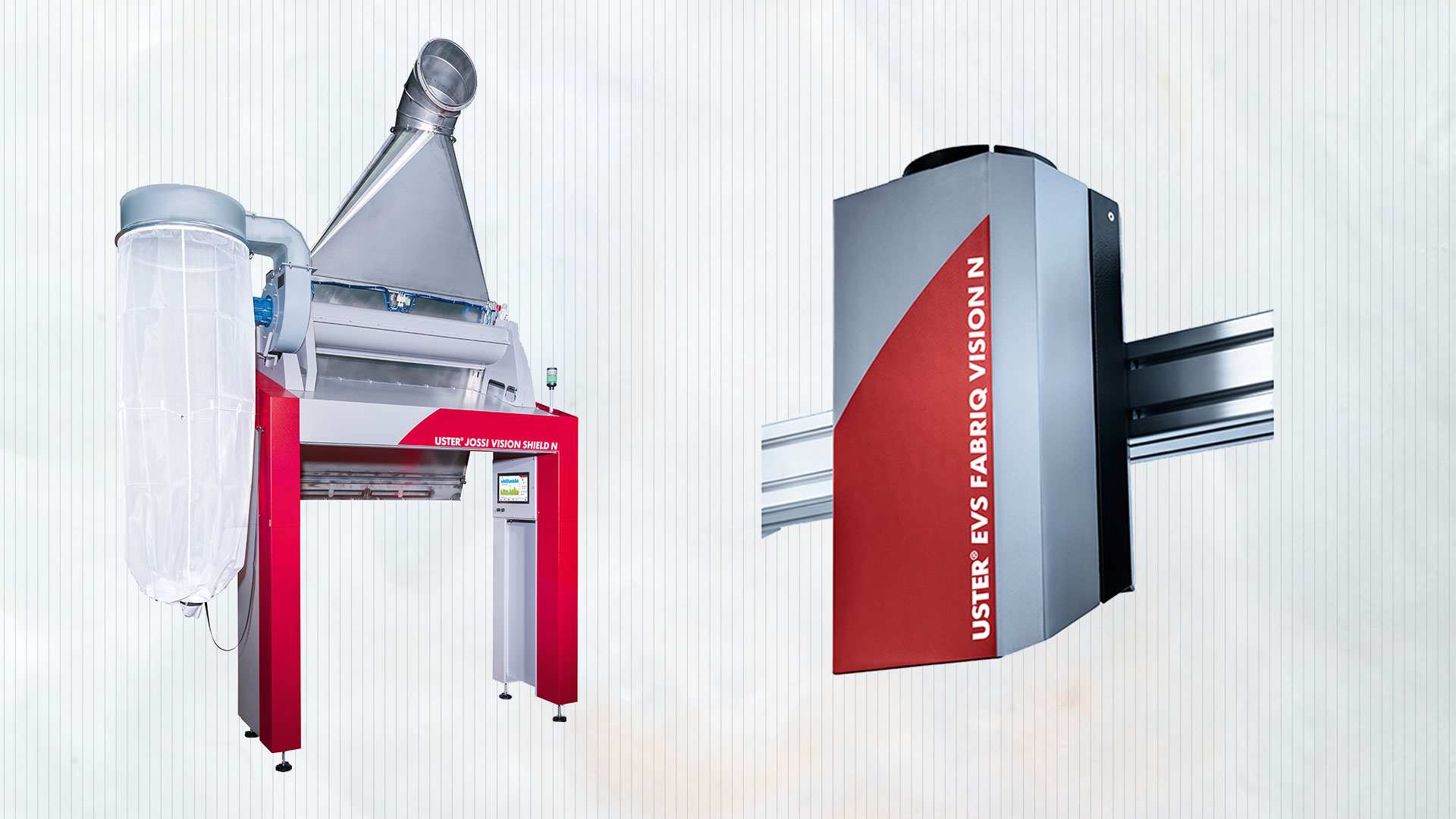

The Uster contamination sorter has powerful imaging spectroscopes that can detect and expel any particle that differs even slightly in color from the main fiber. These imaging spectroscopes capture all types of impurities in cotton or synthetic fibers and can reliably identify them down to one square millimeter in size. Uster contamination sorter, The Uster Jossi Vision Shield N can detect defects in any light pastel, grayish or brownish base material. A further feature is that the Uster Jossi Vision Shield N is ideally placed right after the fine opener, exactly where the contamination cannot be hidden from the spectroscopes. Mario Siegenthaler, Product Manager Fiber Cleaning at Uster Technologies, explains this technology as; “We use our know-how and expertise to further develop technologies in the ‘invisible’ range of IR and UV light for our imaging spectroscopes.”

Today, many nonwovens producers are realizing the expanding commercial potential of recycled fibers. While profit margins look good, it is becoming harder to produce quality products. Siegenthaler continues to his words as; “It is a proven fact that recycled fibers are still today prone to infinite and inconsistent quality variations. Operating a high-performance contamination sorter in the production line is the best way to ensure an acceptable end-product.”

Two-way method to control contamination

Uster uses a two-way approach to improve quality control. In this approach, while Uster Jossi Vision Shield N is located immediately after the fine opener, the Uster EVS Fabriq Vision N is used at the end of the production sequence to automatically identify significant process errors or defects and residual contamination. The company promises nonwovens producers a high level of reliable defect detection, even at full line speeds. In the process, fabrics are automatically graded and inspected. Complete control can prevent any production defects from reaching the end product. Michelle Salg, Product Manager Fabric Inspection at Uster Technologies, discloses: “Uster EVS Fabriq Vision N ensures reliable fault detection by using automated inspection during the production process – and significantly reduces the risk of customer claims. The system’s ability to capture any visible faults also allows web yield to be optimized.”

The company’s methods reliably detect the most common defects such as unopened fibers, neps, black spots, holes and other problems. They help to avoid loss of raw materials, production of sub-standard goods or, worst of all, consumer complaints.