Mimaki, the leading brand of wide-format inkjet printers and cutting plotters, responds to the versatility demanded by the global textile industry with the hybrid technology. Mimaki introduces now the new hybrid model Tx300P-1800 Mkll; its highly acclaimed first hybrid model was introduced to the market last year. Small and medium-sized print service providers have the opportunity to enter new markets with different application possibilities. The hybrid printer provides its users with the opportunity of both direct-to-textile and sublimation printing. Moreover, it can work with more ink types/sets.

The new hybrid textile printer Tx300P-1800 Mkll transforms versatility from a concept to reality. The ability to provide a wide range of applications from fashion textiles to indoor fabrics and wallpaper in one system makes this an ideal entry-level solution. Small print service providers and large volume production houses that desire the benefits of digital printing can handle sample production, low-volume jobs and faster turnaround demands. These digital opportunities, which cannot be achieved with analogue print methods still prevalent in the modern textile printing industry, reach every manufacturer with the Tx300P-1800 Mkll.

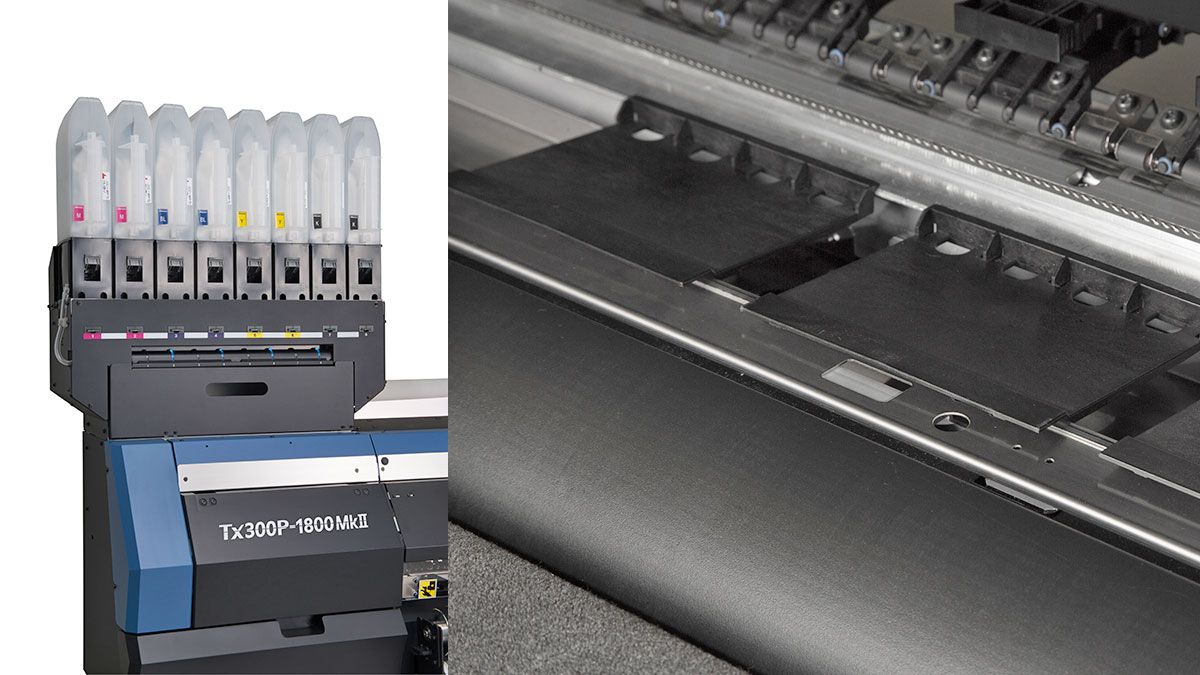

3 different combinations with 5 ink types

Mimaki developed the Tx300P-1800 Mkll hybrid printer, taking into account the success of the Tx300P-1800 direct textile printer and the market demands. The possibility of printing with 5 different types of ink (Reactive, acid, pigment, direct sublimation and disperse) was available in the previous model. This advantageous for textile printers, and now with the Tx300P-1800 Mkll, it has been taken to the next level. Users can print with 5 inks types individually in the new model, or they can create new printing possibilities with 3 different ink combinations thanks to hybrid technology; textile pigment / direct sublimation, textile pigment / sublimation transfer or direct sublimation / sublimation transfer. In short, users have all the necessary equipment to print directly or for transfer printing.

One of the main features of the hybrid structure is the print platens that can be changed easily and quickly. These platens are not required when printing directly on the fabric with any of the 5 inks. The platens are used only when printing on paper in hybrid mode. They can be changed easily and quickly by the operator without the need for a service engineer.

Hybrid technology and Mimaki Core Technologies meet

The new Tx300P-1800 Mkll hybrid printer is equipped with Mimaki’s famous core technologies to guarantee print quality improvement and reliability.

Tx300P-1800 Mkll is equipped with the Nozzle Control Unit (NCU) and Nozzle Recovery System (NRS) to provide uninterrupted printing and minimize downtime, the Mimaki Advanced Pass System (MAPS4) to reduce banding and has new ‘high head gap’ printhead to ensure accurate ink droplet placement. In addition, this new printer features an improved feeding mechanism for both textile and paper feeding.

With the new hybrid model, prints can be produced in rich colour tones and sensitive sophisticated lines. Moreover, it is ecologically suitable because it uses only the amount of ink required.

Users will continue to discover new opportunities

Arjen Evertse, General Manager of Mimaki Eurasia, said that Tx300P-1800 Mkll will change the game in digital textile printing. Underlining that they offer both transfer paper and textile printing with a single affordable and easy-to-use system, Evertse continued his words as follows; “Featuring two new ink sets (direct sublimation and sublimation transfer), this new model provides versatility to keep users exploring different materials and applications. As Mimaki, we carry out intensive R&D to enable different applications. Increasing and differentiating demands can only be met with digital printing.

Tx300P-1800 Mkll will play an important role in the transformation of textile printing. Users have a solution that they can use safely; and comfortably in sample printing or in special works that require quick delivery. In addition, since small companies can find solutions to different needs with a single machine; they have now the opportunity to realize the productions they could not do before”.

With a maximum printing width of 1,920 mm in textiles and 1,940 mm in paper; Tx300P-1800 Mkll can print fashion, interior decoration and car upholstery fabrics, textile signs; sportswear, wallpapers, posters and outdoor equipment such as tents.