ITM 2024 resulted in successful discussions and orders for German textile machinery manufacturer Trützschler Group. Dr. Bettina Temath, Head of Global Marketing at the Trützschler Group, expressed her satisfaction with the exhibition by saying; “We believe ITM is a great platform to present the latest developments and to meet new and existing customers. We are very satisfied with the number of visitors and partners we welcomed to our booth this year.” Trützschler’s booth attracted a diverse array of visitors from multiple regions. “We enjoyed opportunities to connect with customers from many different countries this year. The main share of visitors came from Türkiye, but we also welcomed customers from abroad such as Uzbekistan, Bangladesh, Egypt, Indonesia, Iran and Pakistan.” Temath noted and added that they were delighted with the generous orders they received from Turkish customers during the exhibition.

“ITM once again showed that recycling is a megatrend”

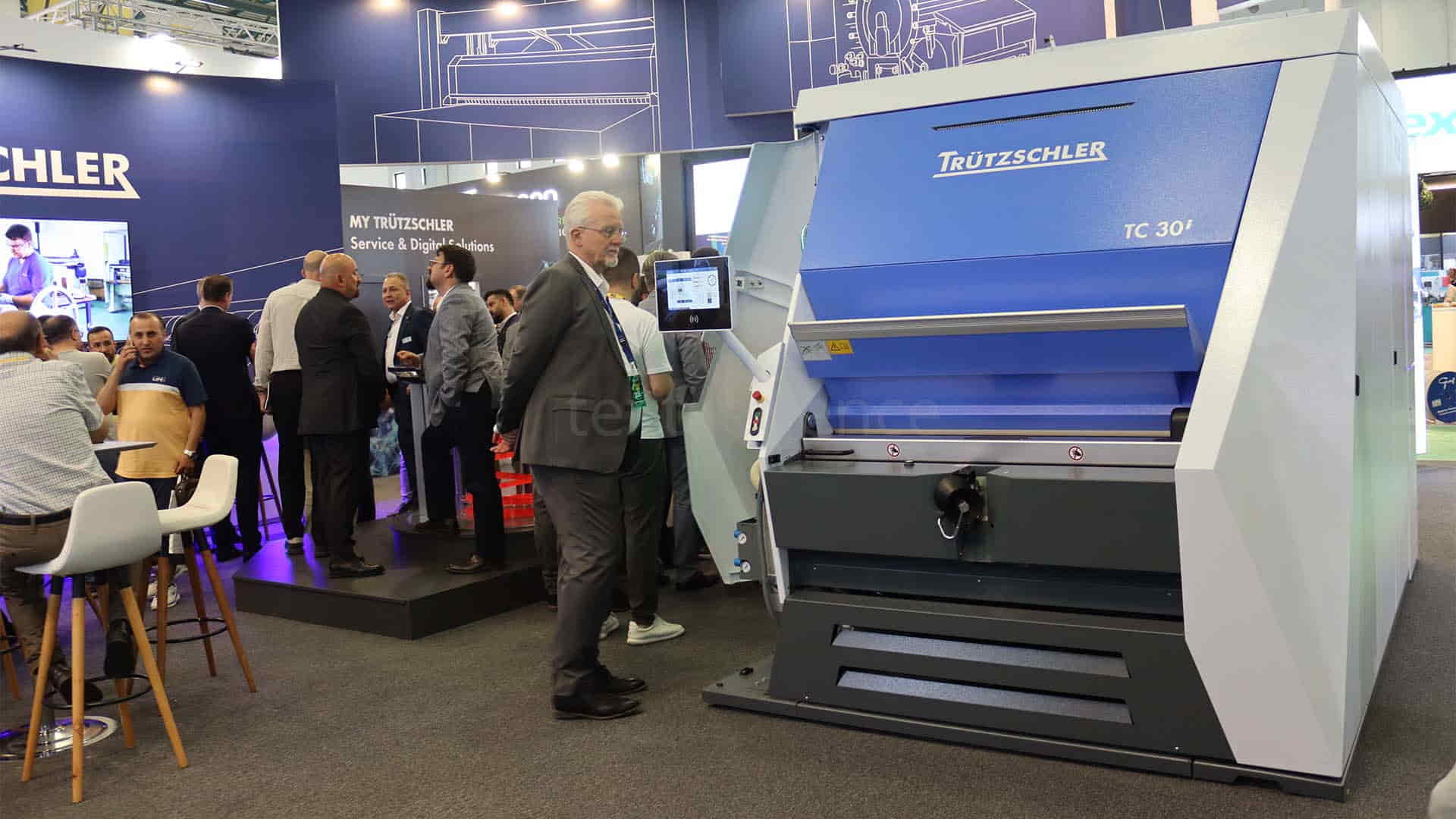

Trützschler showcased several cutting-edge technologies at ITM 2024. Bettina Temath reported on the demonstrations at the Trützschler booth: “Trützschler Spinning highlighted its next-generation card TC 30i, which achieves top quality from any raw material thanks to its enlarged cylinder diameter and higher number of active flats. We also presented our 12-head high-performance comber, the TCO 21XL. It increases productivity by 50 % without sacrificing quality, while also using 25 % less space. Further, we introduced our new integrated draw frame IDF 3 and our latest recycling innovation, TRUECYCLED. We are now offering a complete solution for the processing of post-industrial and post-consumer textiles.” Temath disclosed that ITM once again showed that recycling is a megatrend, especially the manufacturing of products from regenerated fibers and said there was a lot of interest in TRUECYCLED. She added that they also shared insights into My Trützschler, the digital hub for training and service.

Trützschler Card Clothing (TCC) presented a wide range of technologies from its clothing portfolio, which covers the complete spectrum of applications in the spinning and nonwoven markets. One of the highlighted solutions was SUPERTIP. Temath explained the points that differentiate this technology: “SUPERTIP wires are more resistant against wear. That gives them a 30 % longer service life than standard wires on the market. As a result, customers need fewer service interruptions for maintaining the card clothing. That means the machines can achieve better productivity, with lower costs and higher profitability. In fact, SUPERTIP requires 25 % less maintenance time and cuts costs by around 16 %.”

Trützschler Nonwovens spotlighted its latest innovation: T-SUPREMA, a needle-punching line concept that is dedicated to achieving high product quality and system efficiency within the field of premium needle-punched nonwovens. “T-SUPREMA serves as the fundamental component for applications like geotextiles, automotive textiles, filter media and various other industrial uses. The team also provided insights into its high-quality and sustainable nonwoven solutions, with a particular focus on flushable wipes, as well as high-quality baby and body wipes from pulp-based carded/pulp and wet-laid/spunlace lines,” she said.

“We remain optimistic about the future, especially considering Türkiye’s significant role”

Despite current market challenges, Trützschler remains optimistic about the future, especially in Türkiye. Bettina Temath shared her views on the market outlook: “The market is rather quiet at the moment and is in a wait-and-see mode. We noticed this when talking to representatives from the spinning sector and throughout the entire textile value chain. While the market is not very lively right now, we have seen how experts in the textile industry have successfully navigated and improved business situations in the past – particularly in Türkiye. We remain optimistic about the future, especially considering Türkiye’s significant role and its proximity to Europe. Turkish customers value high quality, raw material utilization, energy efficiency and increasing automation. These considerations have guided our approach to innovation and we are convinced that state-of-the-art textile machinery from Trützschler gives our customers a big competitive advantage. The orders we have received during the exhibition confirmed this.”

Trützschler will support all Aegean region from its new facility in Uşak

Bettina Temath replied to our question about their future plans for Türkiye and other markets as follows: “Our goal is unchanged: We strive to provide the best possible service to our customers in Türkiye and worldwide. In this spirit, we frequently review our performance so we can continue to meet the increasing expectations of our customers. We also regularly invest to drive growth. Our new site in Uşak, Türkiye is an example of this. We can now serve customers in the entire Aegean region even faster and more efficiently. And our state-of-the-art electronic repair station in Gaziantep supports our customers with quick and top-class service.”

Temath shared details about the new facility in Uşak: “We are excited about the new location in Uşak. It features a warehouse and offices covering 1,150 square meters of space. This includes a spare parts stock area, a wire winding atelier, a wire stock area and a card repair workshop. We will support all of our Spinning and Card Clothing customers in the entire Aegean region from this facility – even faster and more efficiently.”