More and more companies are now producing recycled yarns on a TRUECYCLED line, state-of-the-art recycling installations, configured and fine-tuned by Trützschler experts based on the customer’s specific requirements. The new complete TRUECYCLED solution, which is the result of the cooperation with Balkan Textile Machinery INC.CO., one of the leading machinery manufacturers in Türkiye, had been announced at the ITMA 2023 in Milan. Since then, Trützschler has received many inquiries for recycling systems.

TRUECYCLED: A holistic approach to textile recycling success

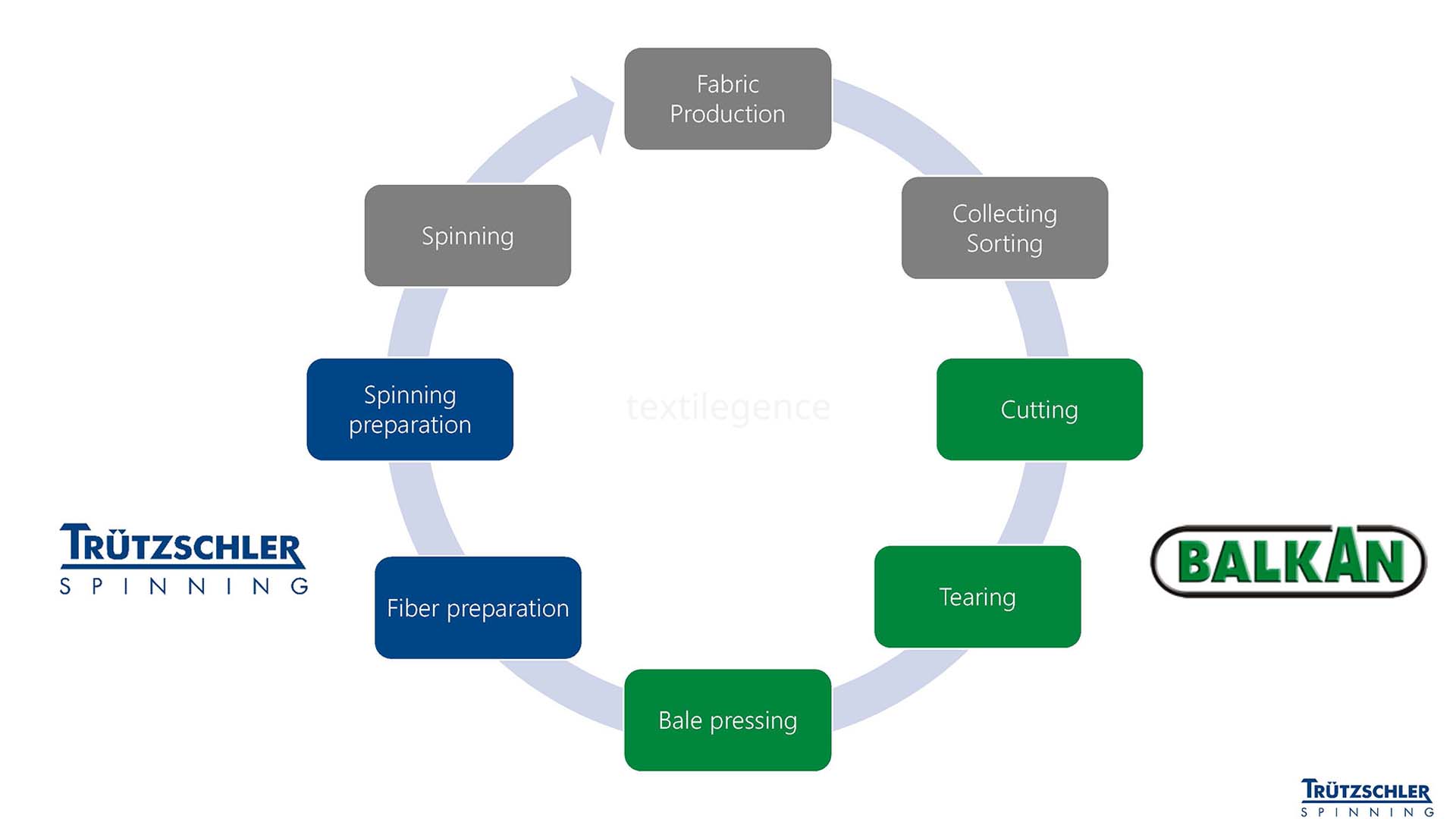

Trützschler has taken a bold step to tackle the global problem of textile waste, expanding its portfolio to become the first full-liner in the preparation of textile waste from mechanical recycling to the spinning preparation of torn secondary fibers. Tearing and spinning preparation are both key processes for achieving the best possible quality from secondary fibers and that means Trützschler’s customers can tap into a competitive advantage by embracing this holistic approach.

Trützschler now offers a complete system covering the whole process, from cutting and tearing textile waste through to carding and drawing secondary fibers. Thanks to this holistic approach and Trützschler’s expertise for the whole process, manufacturers can avoid unnecessary fiber shortening and achieve the best possible quality results.

Success with a systems approach

Recycling systems face significant technological challenges. On average, torn fibers are much shorter than virgin fibers. The percentage share of short fibers in the fiber mass is much higher. Unopened yarn and fabric particles are also difficult to process. Not surprisingly, much academic and practical research is currently conducted to find solutions for these problems. Dr. Georg Stegschuster, a researcher specializing in textile recycling, believes a systems approach is needed. He is working at the Recycling atelier, a model factory for mechanical recycling in Augsburg, Germany, which is committed to delivering the latest technological insights for textile recycling. Stegschuster said that a perfect fine-tuning between tearing and spinning preparation is key for obtaining the best possible quality results and avoiding unnecessary fiber shortening, noting: “This can be achieved if you are in control of both processes – and have the necessary expertise for both processes too.”

Gentle but effective

In some cases, for example, it may be advantageous to have less aggressive settings in the tearing line. This can help avoid unnecessary fiber shortening. The remaining higher share of unopened fabric must then be handled in a high-performance spinning preparation line. This starts with the right blow room configuration for perfect opening, cleaning and blending. A card that is specially designed for recycling materials, such as the new TC 30Ri, can also enable gentle but effective treatment of fibers.

A shortened drafting process is also a must. The integrated draw frame IDF 3 can make this possible. The draft is high enough to provide excellent levelling of the numerous short fibers, but low enough to prevent floating fibers. Stegschuster stated that there is a lot of technological potential for improving the quality of the end-product through the right configurations and settings, saying: “There is a growing number of examples that show how higher quality end-products can be achieved from recycled materials, and how the share of pre- or postconsumer waste in yarns can be increased without compromising on quality.”