Caldera, a software developer for the digital print & cut industry, has announced the support of the latest flatbed printer of UV printing technologies specialist swissQprint, Kudu in its RIP software. swissQprint, represented by Pigment Reklam in the Turkish market, launched Kudu, the first model with 10 freely configurable colour channels at FESPA GPE 2022 in Berlin. This UV-LED printer, equipped with the latest printhead technology for high print quality, further expands the RIP’s portfolio of supported peripherals for large-format printing. The two brand’s solution for obtaining the best colours has already been adopted by thousands of print service providers worldwide to tackle a variety of print & cut, indoor and outdoor applications while increasing their productivity.

Premium components for colour management

Not only does Caldera come with the possibility to use white and varnish spot inks easily, but it also embeds premium components for colour management. The latest version of Adobe PDF Print Engine ensures the accurate reproduction of the designs. The x-rite i1Prism Profiler embedded in EasyMedia makes ICC profiling easy for all users, in order to achieve smooth gradients and accurate colours on all types of substrates.

In addition, customers can also benefit from an optional cost module for CalderaRIP, InkPerformer to optimise ink consumption without compromising on quality. The module, developed in association with the colour expert Alwan, has been designed to help inkjet printers reduce their ink consumption while maintaining colour accuracy and improving grey neutrality.

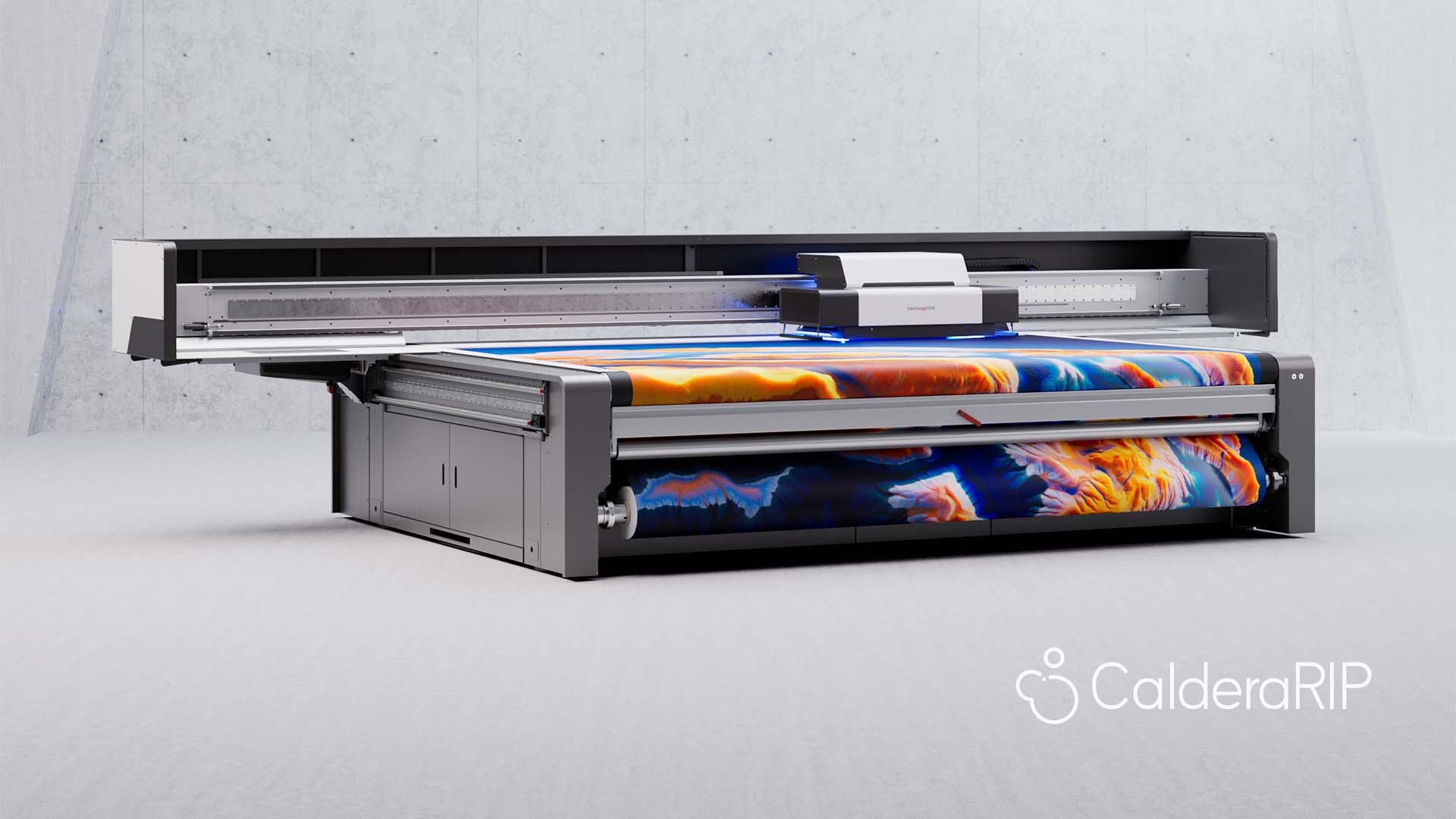

swissQprint Kudu, high-quality even at high speeds

In terms of creativity, versatility and productivity, the Kudu ticks all the boxes of a high-end model with 10 colour channels and its 3.2x2m table. In addition to CMYK, users can supplement the process colours with up to 6 additional channels: light colours, white, varnish, orange, neon or primer for maximum application diversity. Working with a linear drive, this model achieves precise droplet placement power even at high speeds with this feature, which in turn creates a noticeable difference in print quality.