The European textile industry is benefiting from automation solutions these days while reviewing its foreign-dependent structure. With more than 60 years of experience in exclusively designing, manufacturing and installing the highest quality collarette band cutting machines, Svegea offers automation-focused solutions to garment manufacturers worldwide. Triteks Trejd is one of the users of Svegea machines, where tubular apparel components such as waistbands, cuff and neck tapes and other seam reinforcements are produced. The company uses three of latest Svegea collarette cutting machines for manufacturing Tritex Underwear branded products at its factory in Prilep, North Macedonia.

“European textile industry increases its competitive edge with TMAS members”

TMAS Secretary General Therese Premler-Andersson evaluated the relationship between Triteks Trejd and Svegea as a good example of how Swedish textile machinery manufacturers contribute to production in Europe. Arguing that TMAS members, who have a high level of automation and expertise in many areas of technology, support the competitive edge of the European textile industry, Premler-Andersson continued her words as follows:

“Today, business is about much more than just supplying machines or technologies. As suppliers our members understand and are prepared to integrate with the procurement, administration and production and stock handling operations in order to create complete, intelligent systems. This means working closely with customers and supplying a constant flow of ideas on efficiency, quality improvements, reduced waste and adapting for automation”.

Production processes are being reviewed in Europe due to the pandemic

Garment manufacturing was also still a dominant industry across Europe in the first decades of Svegea’s existence, largely enabled by such automatic machine production. However, labour costs became too high in many countries in Europe especially for sewing machinists. As a result, companies began moving their operations, first to nearby lower-wage countries and then inevitably to Asia and the Far East, which is the main destination for Svegea’s collarette machines for knitwear today. At the same time, the company’s expertise has been increasingly turned to the development of bespoke machines for the production of special technical textiles and tailor-made units for specific niche applications.

After the risks posed by long lead times and a total dependence on overseas suppliers, the pandemic process is leading to a reshoring of certain niche textile manufacturing operations in Europe, notably face masks and medical gowns, as well as fast fashion products. From the early 1990s until just recently, however, only the most resilient garment manufacturing companies with highly-automated processes and strong brands retained production in Europe.

Svegea machines ensure fewer production interruptions

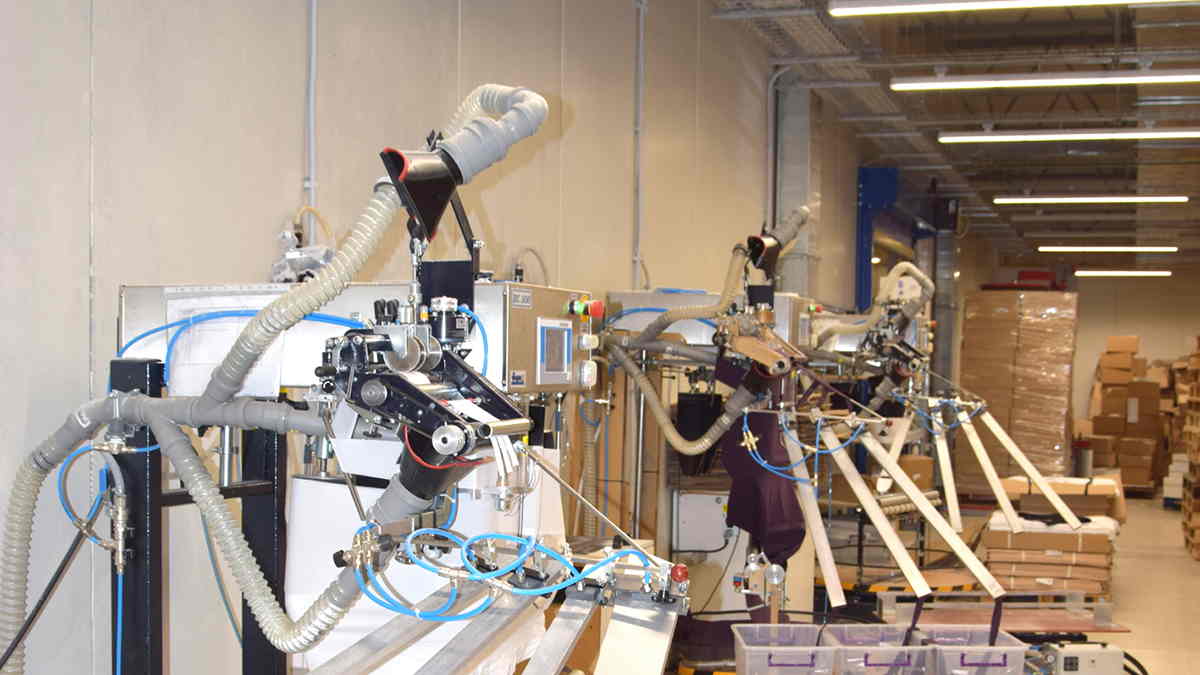

While Svegea’s working speed with its earliest technologies was 360 meters when it was first established, today the most productive collarette machine can reach an output of 20,000 meters per hour. Triteks Trejd currently operates three of the latest Svegea collarette cutting machines and stated that they are highly satisfied with their performance, as well as the service provided by the Swedish company. Plant Manager Dejan Naumoski said that the latest machines are easy to use and that they are very impressed with their precision as well as reducing waste. Naumoski underlined that possible problems are very rare; “These problems are easily solvable and so far, service has been online via viber or mail, and it’s always fast and helpful”.

Svegea General Manager Hakan Steene stated that in recent years Triteks Trejd has replaced the original Svegea collarette machines with highly automatic units with True-Drive control systems. Explaining that they are also equipped with Dust Phantom units to provide an optimum working environment by effectively removing dust and lint, Steen said; “Festooning of the trim from the machines directly into boxes, rather than winding them onto rolls, also ensures less breaks in production for the sewing machinists, with less stretch from the endless material produced”.

“Logistics is a great advantage”

Dejan Naumoski said that now they have all data in real time across all of operations, and concluded his words saying; “Of course, we also make the most of the benefits that our country has to offer. The business climate here is relatively stable and there are qualified and productive workers. The textile industry is highly flexible to the market’s needs, and the country’s proximity to EU countries, as well as well-developed transport and logistics, are certainly a big plus”.