Groz-Beckert needles and tools, the secret heroes behind the high-quality textile products, continue to support its customers for over a century. The German company developing solutions for the changing conditions in time also adds value to the textile industry by cooperating with experts in their fields.

Eric Schöller, Member of the Executive Board at Groz-Beckert, talking to Textilegence, said that the company has been, and still is, in family hands since its foundation in 1852; “Within the textile industry, Groz-Beckert is the world’s leading supplier of industrial machine needles, precision parts and fine tools, as well as systems and services for the production and joining of textile fabrics. Our products and services support the fields of knitting, weaving, nonwovens, tufting, sewing and spinning. Our goal for the future is to continue to offer our customers added value through our products and services, as well as through comprehensive solutions for their production processes. To achieve this, we always believe in strong partnerships with our customers for open exchange, joint innovations, and to create strategic cooperations for mutual benefits” he stated.

He mentioned that they have had numerous successful cooperation projects recently: “We presented some of the latest at the last exhibitions. These include, among others, the development of the INNOTAS knitting system together with Santoni, the innovative compound needle for circular knitting machines together with Vanguard Pailung or the felting needle module which was developed in cooperation with the Dilo Group for their innovative MicroPunch intensive needling technology.”

“Orientation towards fundamental changes is the basis of our R&D”

Eric Schöller shared his reviews on the global economic difficulties and their reflections on production and R&D, saying; “The general worldwide economic slowdown and the lasting structural changes in the global textile markets have been creating a persistently difficult business situation. The immense uncertainties for companies and consumers remained. This was mainly due to geopolitical conflicts and trade disputes. As a result, the willingness to invest and consume was subdued. At Groz-Beckert, this affected the business unit Textile Tools noticeably.” He added that it has become very difficult to predict business developments for 2025 in this outlook: “Overall, we also expect to see a slight improvement in demand and new investments, albeit at a low level.”

He mentioned that China was an exception to the general trend and noted that clothing production in China was stable due to the extremely low prices caused by deflation and the success of ultra-fast fashion platforms: “As these supply consumers worldwide directly from China, their success has had an additional negative impact on traditional clothing manufacturers in Southeast Asia.”

Schöller noted that the orientation towards fundamental changes in the textile industry is the basis for their R&D activities. “With these, we always try to cover long-term trends and thus develop products, services and business models that are tailored to the needs of our customers,” he said. Stating that sustainability has always been one of their core topics, he disclosed that in the future, however, it will also be a matter of developing new business models that meet the customers’ needs even better. He relayed that the world has become more complex in this respect because it has become more individual and short-lived: “Possible solutions can be, for example, pay-per-use models. Surely not relevant for every customer and every segment but for some of them. To this end, we will continue to work closely with our customers and would like to further intensify this, particularly in the area of R&D topics.”

“Textile tools have a direct influence on the quality of the end product”

Eric Schöler emphasised the significant role of needles in production, saying that textile tools have a direct influence on the quality of the end product as well as the productivity in all textile manufacturing processes. “The right tools ensure, for example, an even stitch and a flawless surface. Delicate yarns, for example, require finer needles. Choosing the wrong needle can damage the yarn, which then has a negative impact on the quality and durability of the fabric. In addition, choosing the right tool has an impact on the usable machine speed and the durability of the needle. The examples could be continued endlessly,” he commented.

He also underlined that not only must the correct needle system be selected, but the needle size and point shape must also be adapted to the material being sewn and noted that this often makes choosing the right needle difficult: “With the “Needle Finder”, Groz-Beckert offers an interactive tool to help customers select the right needle. Various product examples with different seams are displayed for this purpose. Selecting a seam shows details of the application, such as the stitch type class. You will also receive recommendations tailored to the product and seam with regard to needle point and needle size. In addition, the most common needle systems used for the chosen seam are suggested. In many cases, the Needle Finder will suggest a different version in addition to the standard needle.”

Groz-Beckert Academy Mobile, organised over 2.800 online seminars in more than 12 languages, also plays an important role for the textile producers: “With the Groz-Beckert Academy Mobile, we offer online seminars on a number of topics related to the textile industry in general and Groz-Beckert products in particular. There are new presentations on interesting and current subjects on a regular basis. The trainings can focus on both global and regional topics. Customized seminars, which are specially tailored to the needs of individual customers, are also possible. You can always find an up-to-date overview of the currently scheduled online and offline seminars on our website,” he said.

“The Turkish market will remain as a centre for management, purchase, and logistics”

Eric Schöller, saying that it was a challenging year for the Turkish textile and clothing industry, shared his reviews on the Turkish market with the words as follows: “Türkiye was affected by the global problems and uncertainties and also had problems due to regional difficulties. Lower demand in export markets (mainly Europe) as well as the domestic market combined with rapidly increasing local production costs (high inflation) and low exchange rates (EUR/TL, USD/TL) created price pressure on Turkish producers and reduced their profit margin and price competitiveness globally. Existing over-capacity as a result of excessive investments in previous years and high interest rates affected investment plans negatively. As a result, Turkish textile and clothing exports declined in 2024 by around 5 % compared to 2023 (end of November 2024).

In 2025 we expect the pressure on exchange rates to be lowered, interest and inflation rates to be reduced gradually and the demand in the main export markets to recover slowly. As a result, the capacity utilization rates and new investments are expected to increase, which will affect our business in Türkiye positively.

In the long term, depending on the above-mentioned economic conditions, Türkiye will continue to be an important market because of its proximity to Europe, short and reliable supply times, availability of high-technology machinery and qualified workforce. Even if the production capacities will not be increased in the future as they have in the past or even maybe partly shifted to lower cost countries in the region (such as Egypt), the Turkish market will remain as a centre for management, purchase, and logistics.”

The patented solution against lint build-up

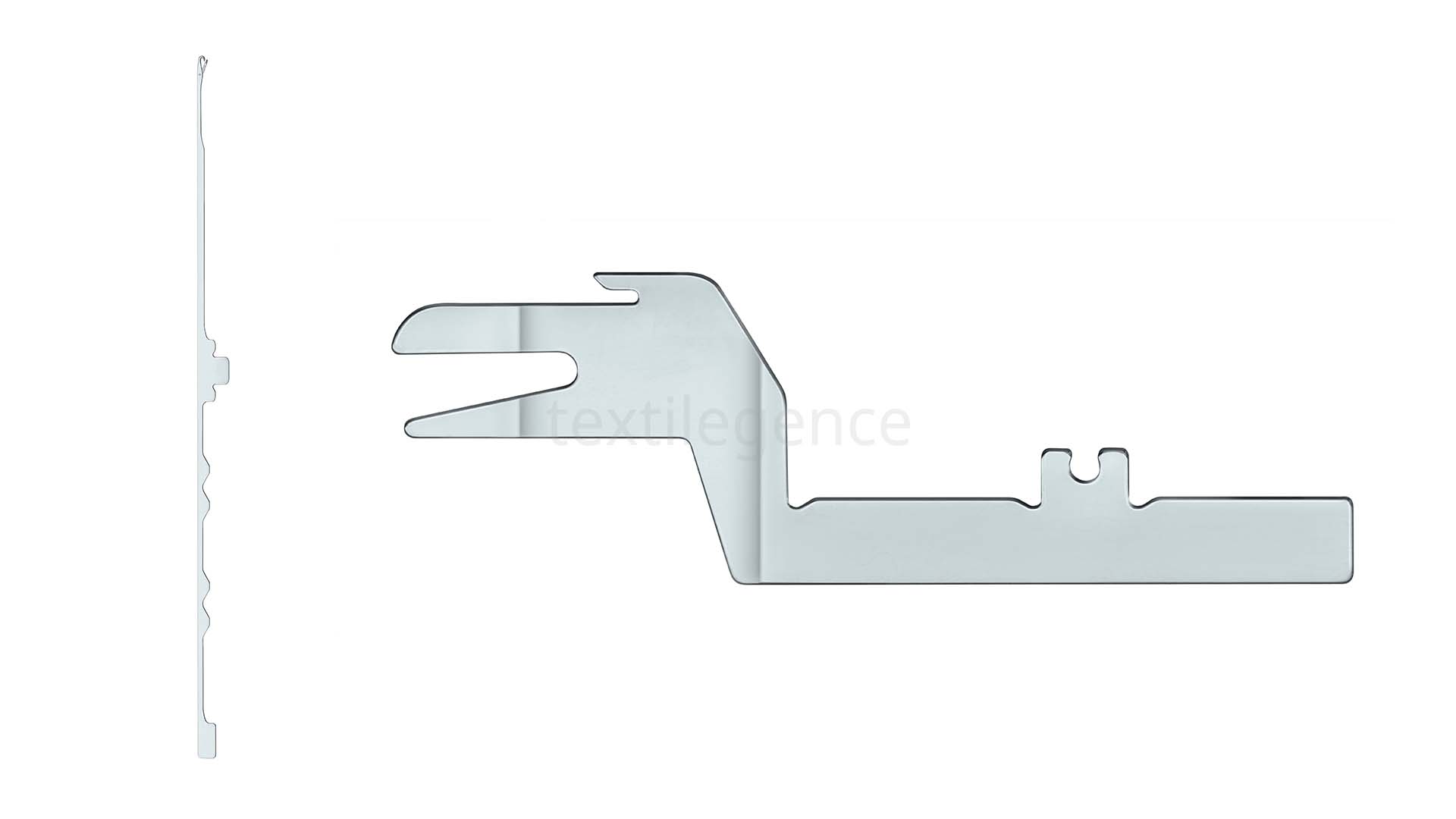

A reliable supplier of top-quality needles, Groz-Beckert is also the choice of its customers when it comes to system parts. Perfectly matched components promise a smooth process and successful knitting results. The Groz-Beckert portfolio includes more than 50,000 products for the knitting industry and two of them, the special application needle SAN™ SF and its perfectly matched sinker SNK SF, were developed to address the special challenges that come with knitting staple fibers. They effectively reduce lint accumulation and significantly extend the time between cleaning cycles and increased productivity and reduced production costs are the result.

Groz-Beckert SAN™ SF special application needle’s unique shank geometry prevents residues from getting under the needles. This means that the machine can run for much longer without the necessity to remove the needles for cleaning, even when processing staple fiber yarns. Therefore, the machine can produce more fabric at the same time. On its lower edge, the shank of the SAN™ SF needle is closed, meaning it has no cut-outs. It therefore fills the entire space, leaving no room for residues to accumulate. The needle stays in its position and keeps the needle track clean for longer. On its upper edge, the shank has humps to transport fibers out of the needle track. As an added benefit, they also support the trick wall if a neighboring needle butt is overloaded in multi-track machines.

Optimal results are achieved by combining SAN™ SF needles with SNK SF sinkers. SAN™ SF needles effectively help to prevent the accumulation of fiber residues and yarn abrasion between the needle back and bottom of the needle track. The special shape of the SNK SF sinker with its opening in the front significantly reduces lint accumulation in the verge ring. This cleaning effect significantly extends the period between cleaning cycles. In field tests, the combination of the SAN™ SF needle and the SNK SF sinker kept the needle tricks clean for three times longer, on average.