The Stäubli TIEPRO warp tying machine, which was first introduced to the market in 2019, was quickly adopted by world-renowned weaving mills. Developed as a result of the company’s closeness to mills, understanding of their needs, and constant and successful collaboration with them, this warp tying machine has the power to respond to the differentiating demands in the market. Covering a wide range of applications, the TIEPRO warp tying machine handles warps with or without a 1:1 lease.

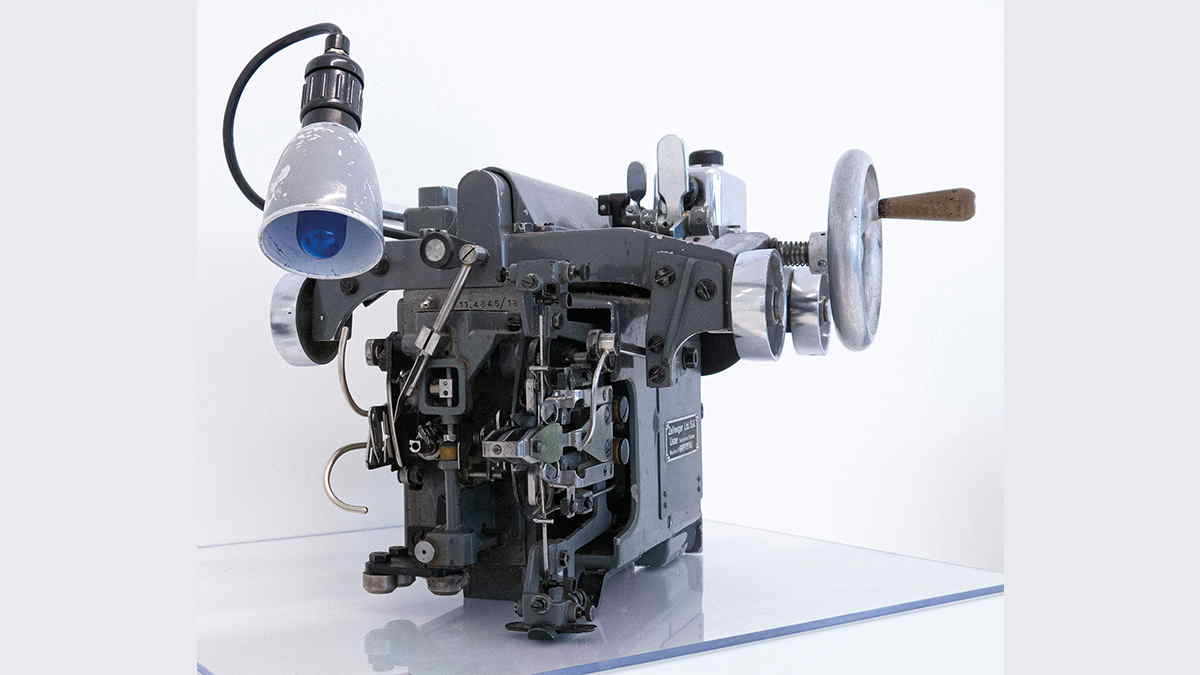

Until the beginning of the last century, the manual warp tying process in weaving mills was an important stage in fabric production. With the mechanization of this process, a new level has been reached in the textile industry. While the first warp tying machines appeared in the 1930s, in that period Uster introduced the KLEINUSTER/USTERMATIC. Subsequently, Stäubli acquired and further developed this product line as part of its global marketing strategy, resulting in TOPMATIC, one of the world’s leading tying machines. As a result of its R&D studies since then, Stäubli has recently introduced TIEPRO, which has come with many new features and is accepted worldwide, to the market.

Activate the Stäubli TIEPRO tying machine with one button

The tying machines to be used in the weaving mill must first be manually placed on the warp tying frame of the weaving machine by the operator. Equipped with robotics, TIEPRO docks itself the old and the new warp sheets, and then starts the automatic warp tying process with the push of the start button by the operator. Thus, staff gets more time to oversee the weaving hall or handle other tasks with time savings acquired.

It prevents misalignments up to 10 mm

Before tying and during the warp stretching process on the tying frame, typically the yarns of the new and old warp sheets are not aligned exactly. While this means an extra waste of time during the tying process, Stäubli TIEPRO easily overcomes misalignments of up to 10 mm, providing precise and quick preparation. Capable of rapid tying up to 600 knots per minute, the machine can be used in all kinds of standard yarns, including 100% staple fibre yarn, 100% cotton and cotton blends.

Another unique advantage of TIEPRO is its automatic Double End Detection (DED), automatically detecting double ends before the warp yarn is cut. Another standard feature, the Auto Reverse function, works with the DED during the yarn separation process, detecting, for example, double ends caused by sticky yarns, immediately extracted and separating them. Thus, this process, which is done automatically in milliseconds and is almost impossible to follow visually, does not require operator intervention. When the process is completed, the yarn separation process starts again automatically.

The only warp tying machine in the world using separation cones

Warp tying machines typically operate using separation needles, while Stäubli TIEPRO is known as the only warp tying machine in the world that use separation cones. Cones made of top-grade, long-lasting materials offer a great advantage over conventional machines that require regular replacement of the separation needles. At the same time, TIEPRO, which makes tying without an oil bath, offers low maintenance and high availability in the weaving mill with these two features.