Weaving and knitting industry’s new technologies developer Stäubli will exhibit the SAFIR S40 automatic drawing in machine for the first time in Turkey at the ITM 2018.

Stäubli will present new machine solutions for the weaving and knitting industries at the ITM 2018 exhibition. The exhibition is a meeting platform for companies of Turkey and the region’s textile industry and the company will meet with visitors in Hall 2 Stand 217. The Stäubli team will inform clients and all other interested parties about the solutions and services during the exhibition.

Stäubli emphasizes the intense global competition the Turkish textile industry is facing, however observes that, Turkey is continuing on its way as a major textile manufacturer in particularly high quality shirt fabrics, denim and carpet. As an industry partner, Stäubli constantly analyses customers’ most important needs and integrates solutions to them in the development of its new products. Working in this way, Stäubli offers an extensive machinery range that perfectly meets weavers’ expectations and offers mills increased advantages in terms of reliability, long service life and versatility in application.

Stäubli’s products for the textile industry are as follows; automatic weaving preparation solutions (drawing in and warp tying), shedding solutions for frame weaving machines (cam motions, electronic dobbies), high-speed Jacquard machines with customer-specific harnesses, carpet and technical textiles weaving systems and automation solutions for the knitting process. Amongst the products being exhibited at the Stäubli’s ITM booth are:

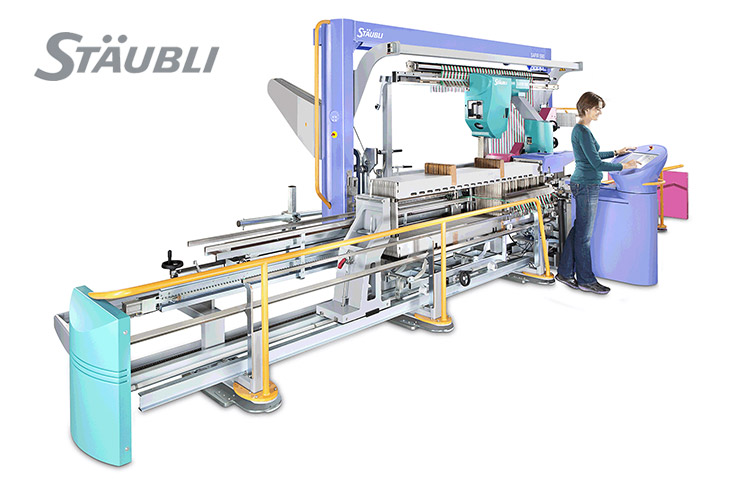

SAFIR S40 drawing in machine – the compact solution for denim and shirting warps

Today, thousands of weaving mills around the world rely on Stäubli-automatic drawing-in machinery that supports an improved weaving preparation process. At the ITM, weavers can see live for the first time in Turkey the SAFIR S40 automatic drawing in machine dedicated to coarse and middle yarn types for denim, bed linen, and shirting fabrics, as well as fabrics for leisure wear. Built of a mobile drawing in machine serving one or more stationary drawing in stations the machine offers compact space requirements and versatile layout possibilities, thus it fits in any mill.

LX Jacquard machine for exquisite flat fabrics, terry cloth and technical fabrics

This quality proven LX Jacquard machine is shown in combination with a Stäubli harness. Built with uncompromising high-quality materials and designed to perform with utmost precision at very high speeds, the LX Jacquard machine allows mills to weave sophisticated fabrics for virtually any application – from colourful African damask to OPW (one piece woven-) airbags, to terry towel.

Stäubli’s Jacquard machinery series LX12 developed for ribbons and labels can be seen at ITM. Easy to adapt and versatile, it is suitable for all types of needle looms and allows a straightforward access for making machine adjustments. It supports excellent results when weaving labels, decorative ribbons, trimmings or elastic ribbons for lingerie.

Dobbies and cam motions for any application

The third generation of Stäubli’s rotary dobbies; the S3060/3260 series, can be seen at the Stäubli stand; and the booths of many other weaving machine manufacturers with different applications. This new generation of rotary dobbies offers new heights of performance and reliability.

Carpet samples showing perfect surfaces and clear designs

Carpet samples demonstrating illustrating technological advancements are shown; including high density applications, weft effects and light carpets.

D4S automatic toe-closing device for an optimized knitting process

The D4S automatic toe-closing device will be presented on a circular sock knitting machine. Visitors can experience how the time consumption in the sock knitting process can significantly be reduced.

Fritz Legler: we are inviting visitors for our innovative solutions

Fritz Legler, Head of Marketing, Sales and Service at Stäubli, announced that they will be attending ITM 2018; with an innovative stand concept that will showcase the product range in the best possible way to all the participating interested parties. Legler continued saying; “Our focus will be on advanced technologies that enable weaving and knitting mills; to continue their business more efficiently and respond to future demands and applications”.

Expressing that Stäubli machinery is the result of years of experience in the textile industry, years of continued R&D and years of continued partnering with customers Legler said their systems and solutions are made of first class materials and are built of robust housings. Legler; “These and many other reasons lead to the fact, that for instance Stäubli machinery can fulfil expectations; such as running reliably at very high operating speeds; and offering a continued weaving process with a minimum of idle time; and resulting in highest productivity, thus during a very long life span. In addition, the continued availability of spare parts and services; is another important advantage that mills that choose Stäubli solutions, are aware of and are continually expecting.”

The Turkish market is doing well but facing the international fashion related downturn in Jacquard weaving notes Fritz Legler. Legler; “This years’ ITM will bring enthusiasm and boost the textile industry to looking positively in the near future”. Stäubli, with its broad product range, can bring further advantages to weavers and knitters in this global situation according to him. Legler added that Stäubli offers the most ideal and appropriate solutions for customer needs; realizes its installation and provides uninterrupted service afterwards; and also trains its customers’ employees.