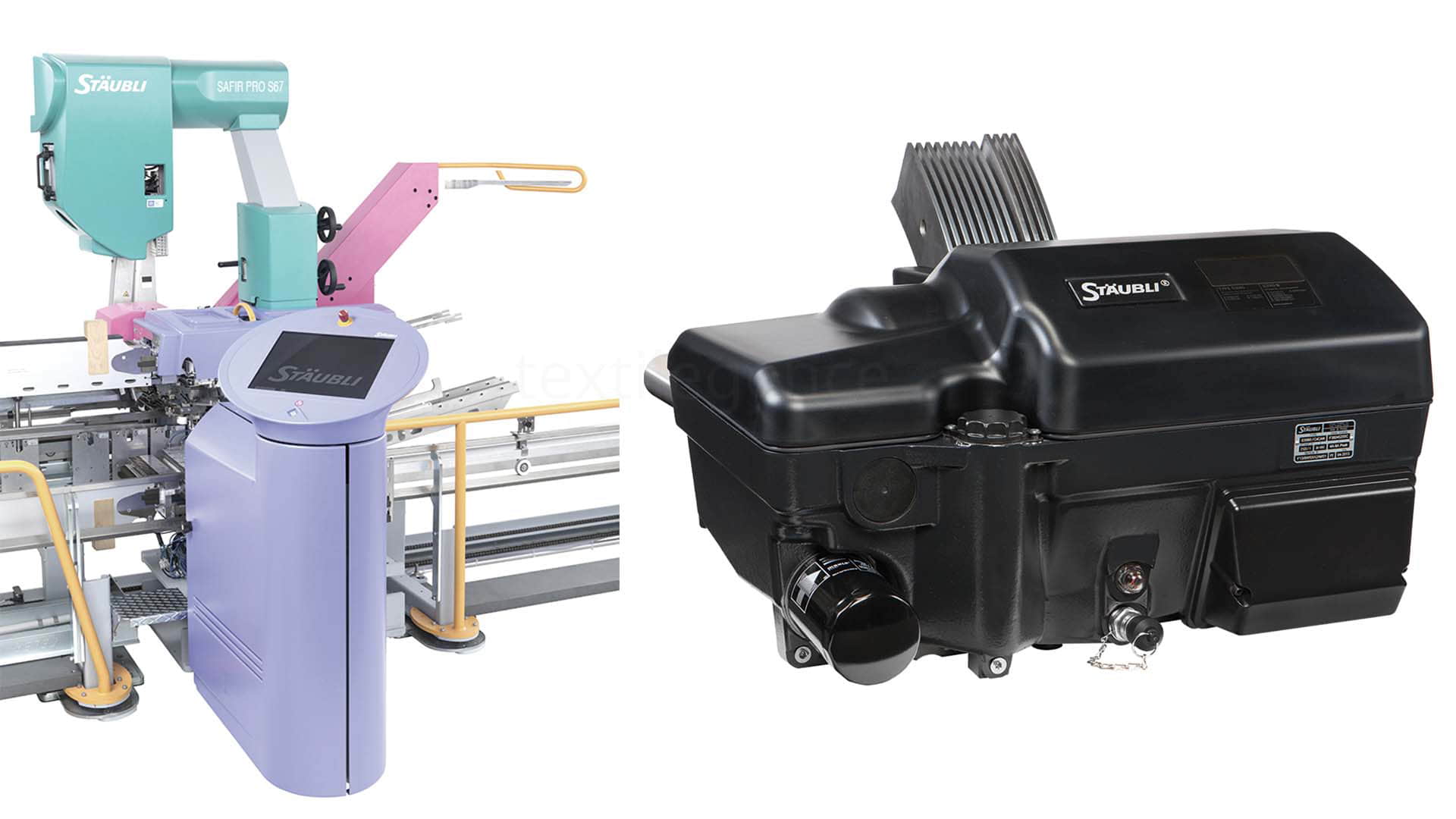

The global mechatronics solutions provider Stäubli will present an overview of its latest high-end technologies, machinery, and solutions that offer the textile industry more and greater benefits at ITM 2024. At the company’s booth numbered 803 in Hall 8, Visitors will discover a novelty dedicated to style changes in the weaving preparation department: SAFIR PRO S67, the new speed generation for the automatic drawing in of colored warps.

The renowned SAFIR automatic drawing-in machines make it possible to shorten workflows, resulting in cost savings and expanding the variety of application possibilities. Equipped with state-of-the-art Stäubli technology, the so-called Active Warp Control (AWC), the SAFIR drawing-in machines feature capabilities such as colour recognition or yarn repeat management. Even warps with multiple colours and without a 1:1 lease can be drawn in, with no error or loss of productivity. The final result is a perfectly drawn-in weaving harness ready for the downstream weaving process. Visitors to ITM 2024 can witness for themselves the impressive speed and efficiency of automatic drawing in with the SAFIR PRO S67 model, dedicated to the needs of cotton fabric mills whose main applications are colored warps for shirting or other.

Visitors will experience speed live at the Stäubli booth

Another crucial process in many weaving mills is warp tying and at this point Stäubli is presenting the TIEPRO warp tying machine together with TPF3B-10 warp tying frame. This machine offers unique features supporting easy start up and processing of the warp to be tied. New staff can easily learn how to run the machine as the screen guides the operator. A standalone advantage of the TIEPRO tying machine is that if a double end is detected, the machine with its exclusive auto-reverse function automatically reverses and redoes that yarn separation step. This process takes place before the yarn is cut. The machine does not require an oil bath and maintains high availability in the mill.

Energy-saving Jacquard weaving solutions

The Stäubli SX PRO responds to market demands for higher power efficiency and lower energy consumption. It incorporates all of the proven Stäubli Jacquard technology as well as several innovations to reduce energy consumption: low-friction design of the MX PRO module, power supply fully integrated into the machine itself, and a new ventilation system with optimized temperature monitoring. Equipped with up to 2,688 hooks, the SX PRO is perfectly adapted to the needs of the Turkish market, where terry cloth, apparel fabrics, tapestries, and upholstery fabrics are produced. Visitors to the Stäubli booth can observe the new SX PRO Jacquard machine in combination with a Stäubli harness at a demonstration stand.

Shed formation for high-speed frame weaving

The rotary dobby is a revolutionary machine invented by Stäubli many decades ago, and Stäubli has been continuously developing it further. The third generation of electronic rotary dobbies, the S3000 / S3200 electronic rotary dobby family, is an evolutionary design. It incorporates the unique Stäubli locking system, which provides enhanced security for the selection of the heald frames, allowing higher running speeds and superior reliability. This latest generation of electronic rotary dobbies offers astounding benefits to weavers.

Last year weavers could discover the brand new S3280 electronic rotary dobby concept in Milan, now visitors to ITM 2024 can discover it in Istanbul. This dobby is designed for ultra-high-speed operation, a minimum of vibration, and extremely reliable performance. Coupled with the new e32/33 G transmission, the S3280 is a must-have solution for frame-weaving mills that demand the utmost in productivity.

During the exhibition, latest carpet samples woven on the ALPHA 580 UNIVERSAL can be seen at the Stäubli booth as well. More examples of the company’s products, in applications with Jacquard machines, dobbies, and cam motions can be seen during ITM 2024 at various booths of Stäubli partners.