Baldwin Technology Company Inc. will show the textile supply chain how to ‘Finish with Perfection’ at ITMA 2023 with its TexCoat™ G4 precision spray finishing system, eliminating chemistry waste on changeover, saving water, and achieving faster speeds through the stenter frame and relaxed dryer. Plasma Pure treater will also include at the company’s booth stand H-14-C205. ITMA participants can stop by and ‘touch’ Baldwin’s wide array of TexCoat G4-applied fabric samples from textile mills around the world and experience what precision finishing ‘feels’ like. Experts will be on hand to discuss how Baldwin Technology can assist in transitioning the textile supply chain to reach their sustainability and carbon footprint goals while improving performance and saving money. In addition, New testimonial videos from Pincroft Dyeing and Print Works and Graniteville Specialty Fabrics along with a video highlighting Baldwin’s partnership with North Carolina State University will premiere on the big screens at the Baldwin booth.

Textile manufacturers increase profitability with Baldwin’s TexCoat G4

Baldwin’s VP Global Business Development, Textiles Rick Stanford said that since its introduction at ITMA 2015 in Milan, global textile finishers have embraced TexCoat and reaped the benefits and stated: “They have been able to increase profitability, cut energy use, and reduce their carbon footprint in addition to exercising precision control with patented precision spray technology.”

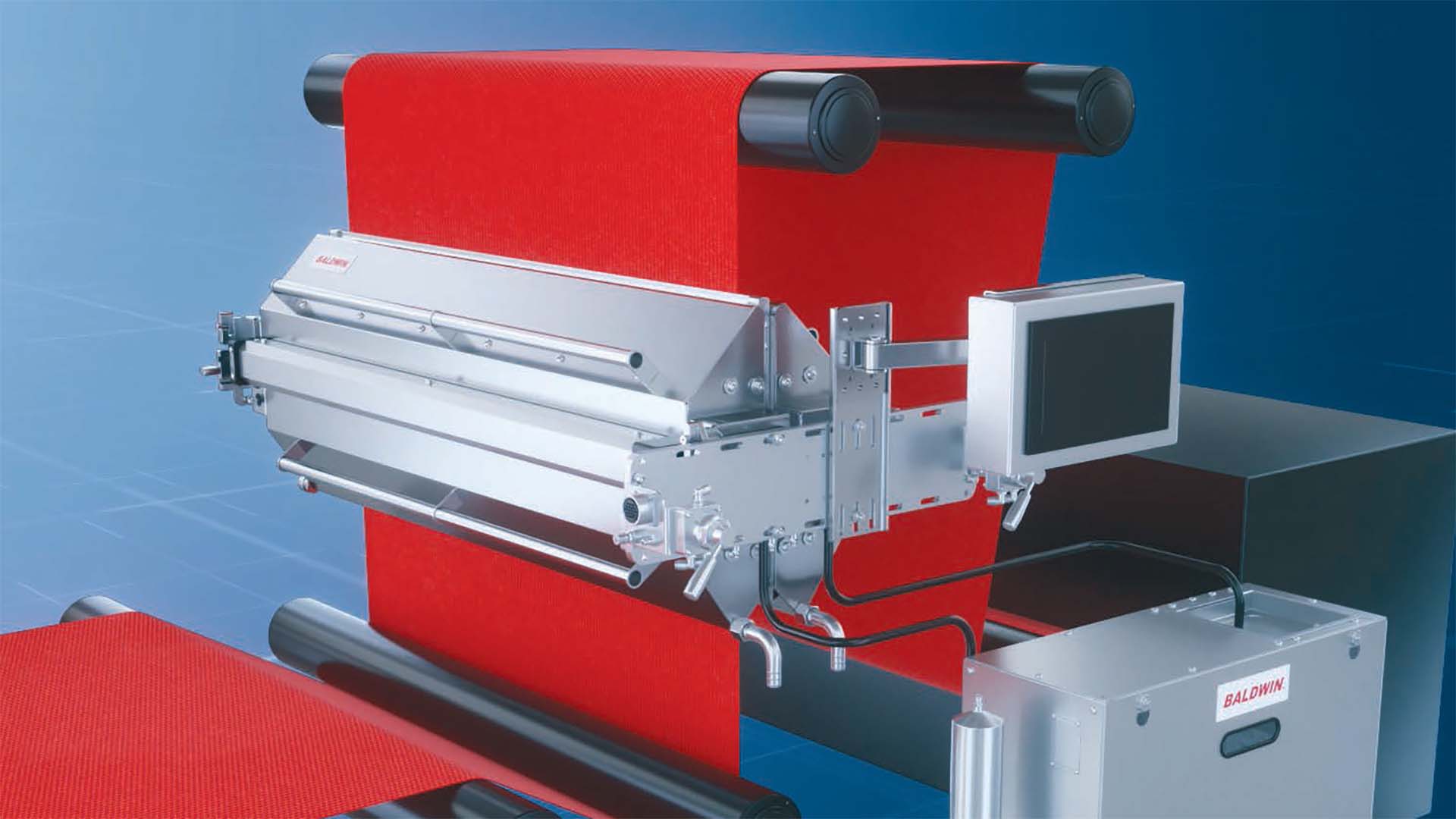

TexCoat G4’s non-contact spray technology offers numerous advantages compared to old and commodified methods of applying finishing chemistry. The system processes a wide range of low-viscosity water-based chemicals, such as durable water-repellants including PFAS-free, softeners, anti-microbials, easy-care and flame retardants, just to name a few. The company’s technology uses the same chemicals as found in traditional pad baths with no special auxiliaries required.

In addition to TexCoat G4, Baldwin is offering its Plasma Pure treatment for textiles. The system enhanced and more efficient dyeing, coating and lamination of textiles and nonwovens. Its ceramic electrodes generate an air plasma used to efficiently treat the fabric surface. Key benefits include dramatically improved absorption and adhesion properties of the fabric, boosting productivity while enhancing the absorption properties with an optimized and uniform dyeing result and a significant acceleration of the absorption process. Laminated fabrics benefit from Plasma Pure technology with greater bonding strength.