Rieter innovations in rotor and compact spinning. Rieter was the center of innovations that attracted the interest of visitors from the first day of the exhibition until the last day in Hall 6 Booth C 201 at ITMA 2019. On the first day of the exhibition, a special demonstration was held for the press members presenting Rieter’s latest developments in fibre preparation, spinning preparation, spinning, automation and digitalization. In the presentation made by Norbert Klapper, CEO of Rieter Holding AG, important technical features were announced while the launch of new machines were made one by one.

The first innovation introduced was the new direct rotor process. The RSB-Module 50, the draw frame module on the C 80, the most efficient card in the industry, improves system performance and yarn quality even with low-cost raw materials. With the largest active carding area in the world, this card saves up to 20% energy. Thus, quality-oriented spinners can benefit from efficient raw material utilization and excellent yarn quality.

Another innovation is the fully automatic rotor spinning machine R 70, which combines the advantage of the Rieter spinning box with optimal arrangement of individual drives at each spinning position. The results are maximum productivity, raw material cost savings, and low energy requirements.

Rieter innovations

Other innovations included the comber E 90, the fully automated roving frame F 40; the piecing robot ROBOspin and three different compacting units (COMPACTdrum, COMPACTapron and COMPACTeasy). The E 90 Comber offers the highest productivity and a wide noil extraction range for maximum flexibility. Impressing with its fast bobbin change and high efficiency; the F 40’s precise bobbin build-up provides the perfect feed for quality yarns. The three new compacting devices can be quickly and easily installed on or removed from a ring spinning machine.

Another innovation presented was the ring spinning machine G 38 for maximum flexibility and future-oriented automation; which flexibly produces high-quality standard and special yarns with high performance. The ROBOspin, the first reliable piecing robot in ring spinning, was also among the innovations of interest. Rieter has responded to the expectations of the textile industry with the ‘ESSENTIAL’ management system, which connects all digital applications. ESSENTIAL connects all production, machinery and auxiliaries in spinning mill management.

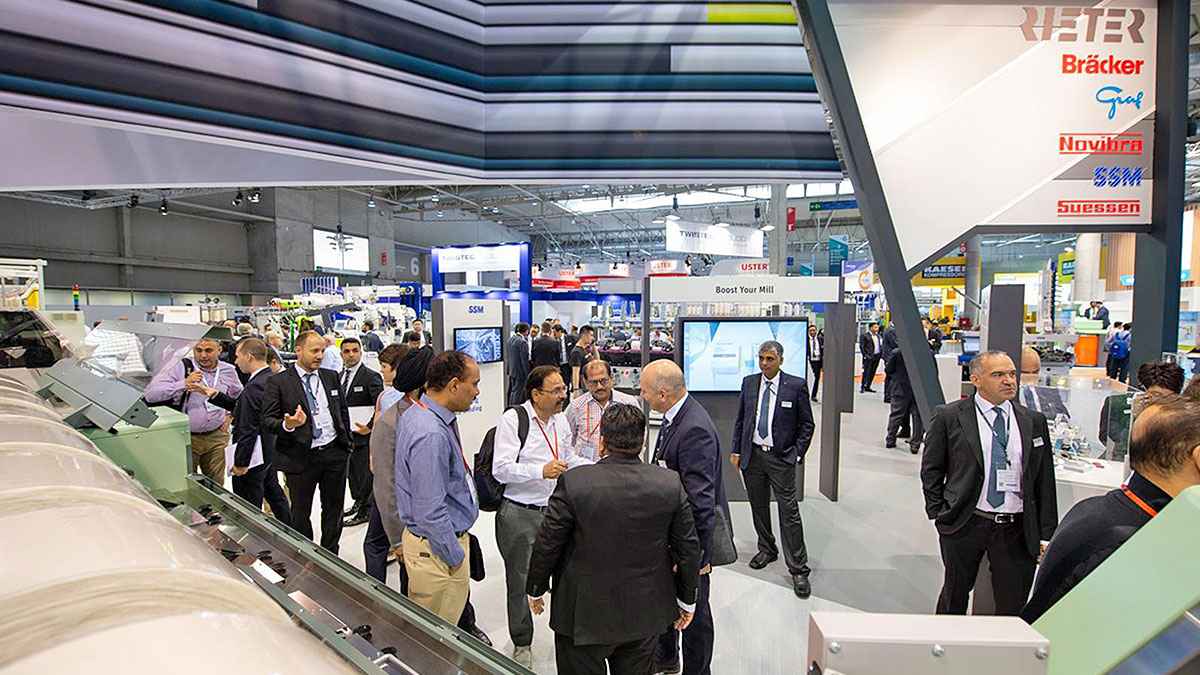

The Rieter booth in Hall 6 featured SSM, Suessen, Novibra, Graf and Bräcker brands. Rieter also presented Com4® yarns and their advantages in supply at the booth in Hall 3.

Rieter signs agreement for modernization of Egyptian textile industry

At ITMA 2019, Rieter not only introduced their innovations to the industry, but also signed large-scale agreements. They have signed agreements with the Egyptian capital Cairo-based Cotton & Textile Industries Holding Company for seven projects worth 180 million Swiss francs. The orders covering compact and ring spinning systems are part of a comprehensive modernization program for the Egyptian textile industry.