Global Textile Group, one of the leading textile companies in Uzbekistan, uses Rieter‘s COMPACTeasy solution to convert ring yarn into compact yarn at its Fergana Global Textile (FGT) factory. FGT, installing the compacting device on its existing ring spinning machines G 37, provides higher yarn quality and better performance in downstream processes; as well as the ability to switch between the production of ring and compact yarn. The company’s Fergana Global Textile factory produces 26 tons of carded yarns and 12 tons of combed compact yarn as well as 20 tons of blended yarn from cotton and polyester per day. As a vertically integrated company, it processes cotton grown on its own fields in a ginning plant and also started to produce dyed knitted fabrics. The yarn and fabrics are certified with Oekotex Standard 100 and are sold to sewing and knitting mills of big brands mostly in Europe.

Fergana Global Textile CEO Otabek Nishanov described the advantages of the COMPACTeasy compacting device as follows; “The comber E 86 and the installation of the compacting device COMPACTeasy on our ring spinning machine were accompanied by excellent service and timely support from Rieter field service staff. The compacting device gives us the opportunity to add value to our yarns while using existing equipment. This not only strengthens our own fabric production but also helps us meet the needs of our customers and forge new partnerships”.

From ring to compact yarn with COMPACTeasy

The combination of Rieter’s E 86 combers and the COMPACTeasy compacting device responds to FGT’s search for a straightforward solution to upgrade its ring yarn to compact yarn without requiring serious assembly labour and high investment costs. COMPACTeasy features a compacting system with a y-shaped channel, enabling intensive double compacting without any additional energy consumption. The yarn quality is determined by both the y-channel of the compactor and the integrated pin in the fibre drafting system area (the area where they have the least guidance). The compacting device can be easily retrofitted on existing machines.

7% more productivity

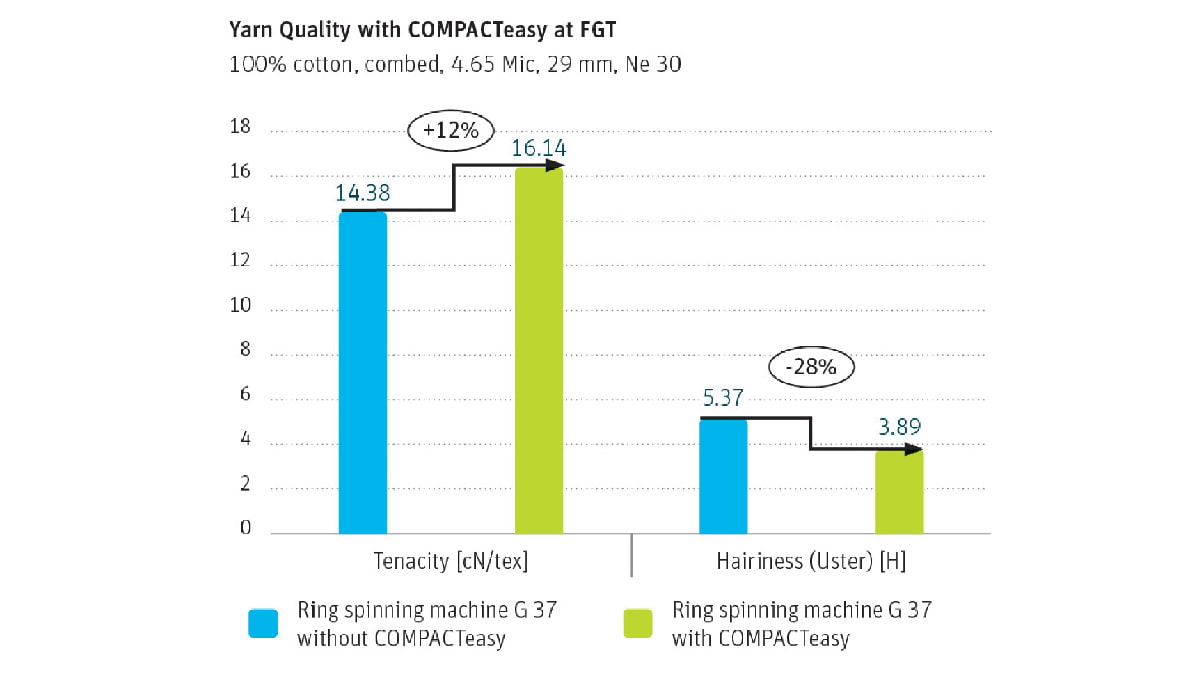

FGT has upgraded its ring yarn to compact yarn by using the comber E 86 in spinning preparation and by installing the compacting device COMPACTeasy on its ring spinning machines G 37. While the productivity on the G 37 has increased by 7% with the production of combed compact yarn, the compacting device was plugged out at several spinning positions to compare the yarn quality produced on the G 37 with and without COMPACTeasy. As a result, combed ring and combed compact yarn (from 100% cotton with a yarn count Ne 30) were produced on the same machine, and it was concluded that the results for unevenness were similar for both the ring and compact yarn. In terms of hairiness and tenacity, the compact yarn achieved a significantly better quality: hairiness was 28% lower and tenacity was 12% higher.

COMPACTeasy offers flexibility against changing market demands

Not only does COMPACTeasy offer higher yarn quality, but it also has a positive effect on downstream processing. FGT detected the better performance of the knitting machines in the compact yarn processing process and confirmed this with less pilling seen in the fabrics produced. The compacting device can be easily plugged out from the G 37 without using any tools to switch to the production of ring yarn again. This offers a high level of flexibility when faced with market requirements that are constantly changing.