Oerlikon Nonwoven will take place with its wide product portfolio at INDEX, the world’s leading nonwovens trade fair, which will be held in Geneva, Switzerland on October, 19-22, 2021. Offering market and customer-oriented system solutions for filtration, hygiene and medical, geotextile and other industrial applications, Oerlikon Nonwoven will introduce its products that provide the optimum production process for every application. Visitors will have the opportunity to examine the products on display both on the Oerlikon’s physical booth no. 2314 and on the online platform during the fair.

Highly-sophisticated fabrics with Oerlikon Nonwoven Meltblown technology

Oerlikon Nonwoven’s Meltblown technology enables the easy and efficient manufacturing of unique and highly-sophisticated nonwovens for filtration, insulation and sorption applications. From classical polyolefins (PP, PE), PET, PLA, PBT and PA to special plastics such as PPS and TPU, all these and other raw materials, can be reliably processed with the Oerlikon Nonwoven Meltblown procedures.

Here, filter efficiency is further increased by using the integrated ecuTEC+ electro-charging unit for electrostatic charging of filter media. The extreme flexibility distinguishes it from other concepts currently available on the market, while the user can choose from a wide variety of options and set the optimum charge intensity for filter applications.

Low energy consumption, high production for technical fabrics

Oerlikon Nonwoven’s systems provide high production capacities and efficiency at low energy consumption for technical fabrics. In this way, for example, geotextiles made from polyester or polypropylene can be efficiently manufactured with running meter weights of up to 400 g/m2 and filament titers of up to 9 dtex. In addition, Oerlikon Nonwoven offers specialized spunbond processes for the production of nonwoven substrates for roofing underlays (PP or PET spunbonds) and so-called bitumen roofing substrates (needled PET spunbonds) for bitumen roofing membranes.

In particular, Oerlikon Nonwoven’s several years of core-sheath bi-component experience allows to realize of completely new nonwoven structures and hence the incorporation of various functions in a single material. The core-sheath bi-component spinning process permits various combined fibre cross-sections and also simultaneously different fibres to be produced from a single or different polymers with this method. The spectrum ranges from core-sheath and side-by-side bi-component filaments, splitable fibres all the way through to so-called mixed fibres.

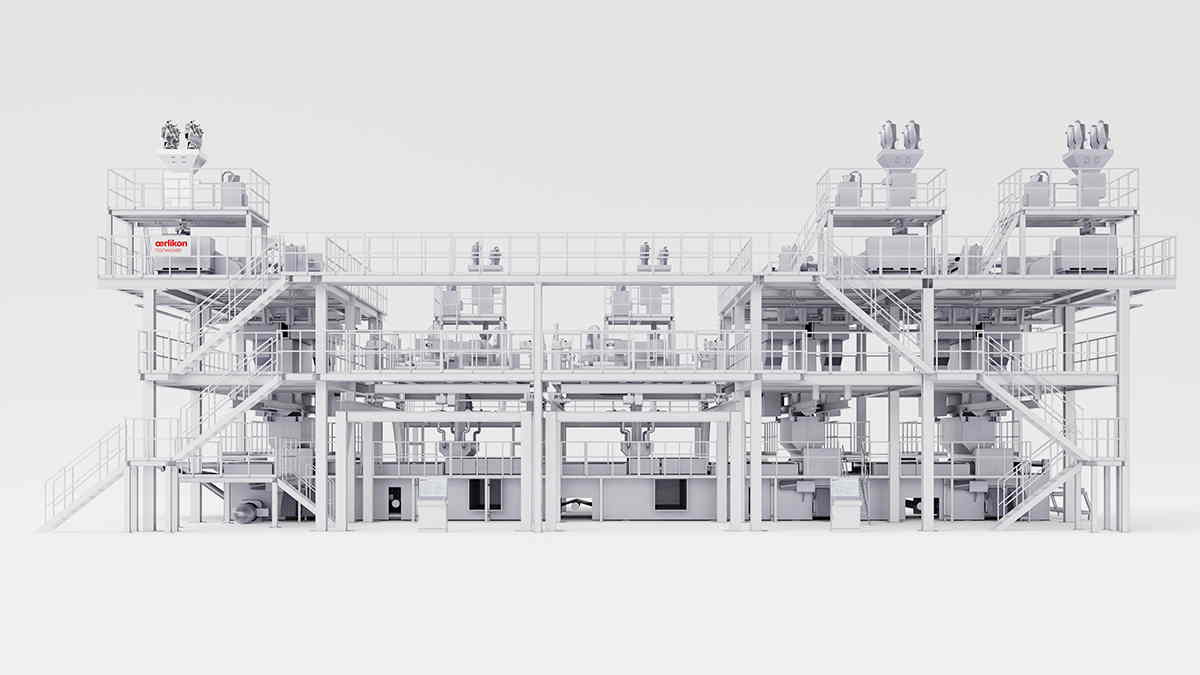

Competitive solution in the production of hygienic and medical nonwoven fabrics

For manufacturing hygiene and medical nonwovens, the QSR (Quality Sized Right) technology offers a cost-effective solution to produce these highly-diverse spunbond and meltblown composites (SSMMS, SMMS, SSS, etc.) in accordance with globally-accepted standards. Oerlikon Nonwoven is able to equip this type of system with unique features with special nonwoven properties such as higher volumes, softness and customer-specific embossed patterns thanks to intensive collaborations and partnerships, close-knit quality assurance measures, as well as extensive interaction with its technology partners. In this way, producers have the opportunity to differentiate themselves in their markets.

Phantom technology for wet wipes production

Oerlikon Nonwoven offers an alternative co-form technology with Phantom platform, enabling the manufacturing of different wet wipes from pulp and polymer fibres. In addition, the Spunmelt and Airlaid processes are combined in a manner that the properties of the starting materials are ideally units. While the material mix can comprise up to 90% cellulose fibres, cotton and synthetic fibres can also be added.

Phantom technology has the advantages of being ecological as well as performance and cost advantages compared to processes such as classical spunlace produced to date. While dispensing with hydroentanglement renders subsequent drying of the material redundant; Product parameters, such as softness, tenacity, dirt absorption and liquid absorption, can be optimally set. Phantom technology enables the production of both flexible and absorbent structures as well as highly-textured materials.

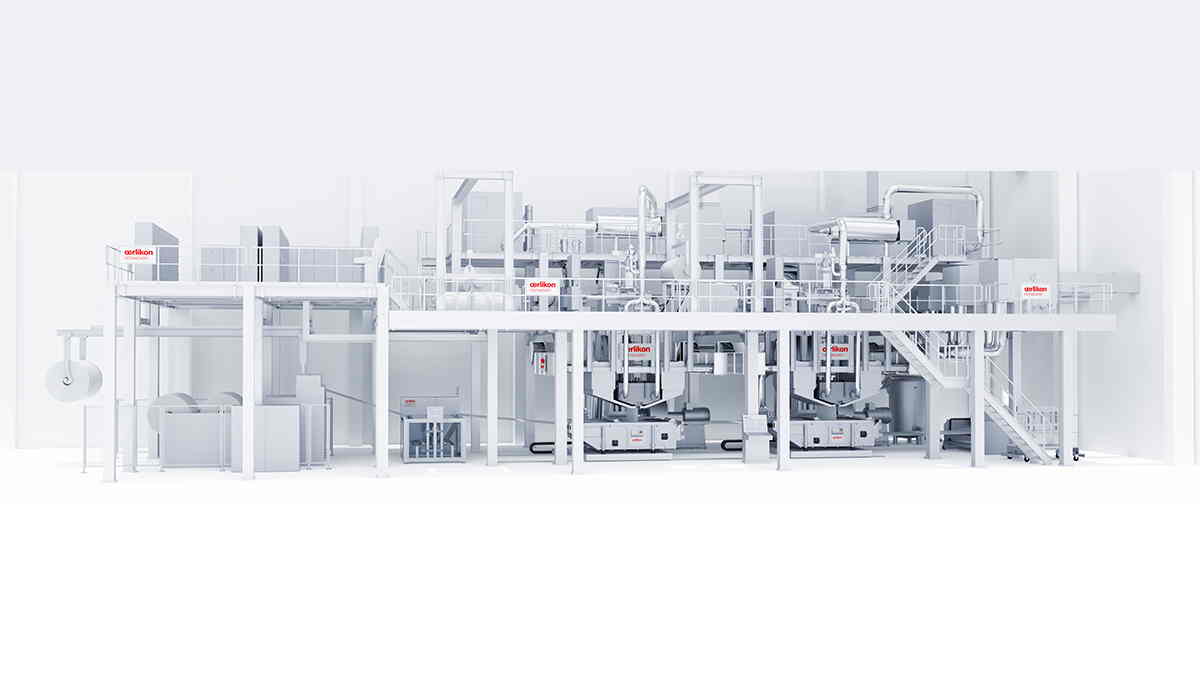

Sustainable nonwovens with Airlaid technology

Pulp or cellulose fibres as raw materials for manufacturing nonwoven fabrics are in an unrivalled position in terms of sustainability and environmental compatibility. The Oerlikon Nonwoven Airlaid process offers an ideal solution for processing this raw material into high-end products for numerous applications.

Today, while the production of high quality lightweight Airlaid nonwovens with economically attractive production speeds and system throughputs is in high demand, Oerlikon Nonwoven’s patented formation process is setting the standards for homogeneous fibre laying and superb evenness in low running meter weight fabrics, too. Furthermore, it permits the homogeneous mixing of the most diverse raw materials, including pulp, short- and long-staple natural and manmade fibres (up to 20 mm) and powders, as well as the utilization and combination of the most diverse mechanical, thermal and chemical tangling methods for creating the requisite product properties.