The Swiss Oerlikon Group’s Polymer Processing Solutions division presented itself under the banner of ‘Feel the Flow. Keep Control’ at the K 2022, one of the leading international trade fairs for the plastics industry, held in Düsseldorf, Germany, on October 19-26. Oerlikon showed a broad range of products and services focused on manufacturing and processing plastics at Stand D10 in Hall 1. Innovative solutions and technologies concentrating on such topics as raw material preparation based on modern polycondensation and extrusion systems, the latest recycling technologies, efficient hot runner systems, innovative coating solutions, sustainable manufacturing processes for filtration applications and high-quality gear metering pumps were the center of the visitors’ interest during the fair.

Oerlikon supports manufacturers in achieving their own sustainability targets

The Oerlikon Polymer Processing Solutions division CEO and Oerlikon Group CSO Georg Stausberg stated that they see their technology solutions as enablers of a better world, saying: “In the polymer processing industry, we have to come to a sustainable, closed circular economy for packaging materials and textiles, for example, while simultaneously intensively expanding the recycling of the materials used. With our current technologies and our future innovations, we support manufacturers along the entire process chain in achieving their own sustainability targets.”

Head of Marketing, Corporate Communications and Public Affairs at the Oerlikon Polymer Processing Solutions division, André Wissenberg noted that longer service lives for components and tools increase efficiency in plastics-processing manufacturing, and also provide for more stable processes and hence less waste. Wissenberg added all their technology brands and the innovations being presented at the K 2022 have a clear focus on this these.

From sustainable solutions to virtual experiences

Oerlikon attended K 2022 with numerous attractive solutions and one of them was Oerlikon Barmag Huitong Engineering continuous polycondensation systems. High-quality melt has a direct impact on the end product and it forms the basis for high-end bottle, film and fiber polyester. Oerlikon’s efficient and high-quality systems produce homogeneous melt by means of a chemical reaction during which different monomers are joined together to create polymers.

Oerlikon Barmag also exhibited various solutions including eccentric screw pumps for conveying highly-filled, high-viscosity and abrasive media on the occasion of the K 2022. Furthermore, there was also a spotlight on a new pump for conveying high-viscosity, shear-sensitive materials such as adhesives and silicones. Using virtual reality glasses, visitors had the opportunity to delve into the pumps themselves.

Hot runner specialist Oerlikon HRSflow showcased a comprehensive hot runner assortment that is tailored to small shot weights as well as its new Xp nozzle series for use in thin-wall injection molding. Both support the trend towards greater sustainability by helping to reduce energy and material consumption in plastic processing.

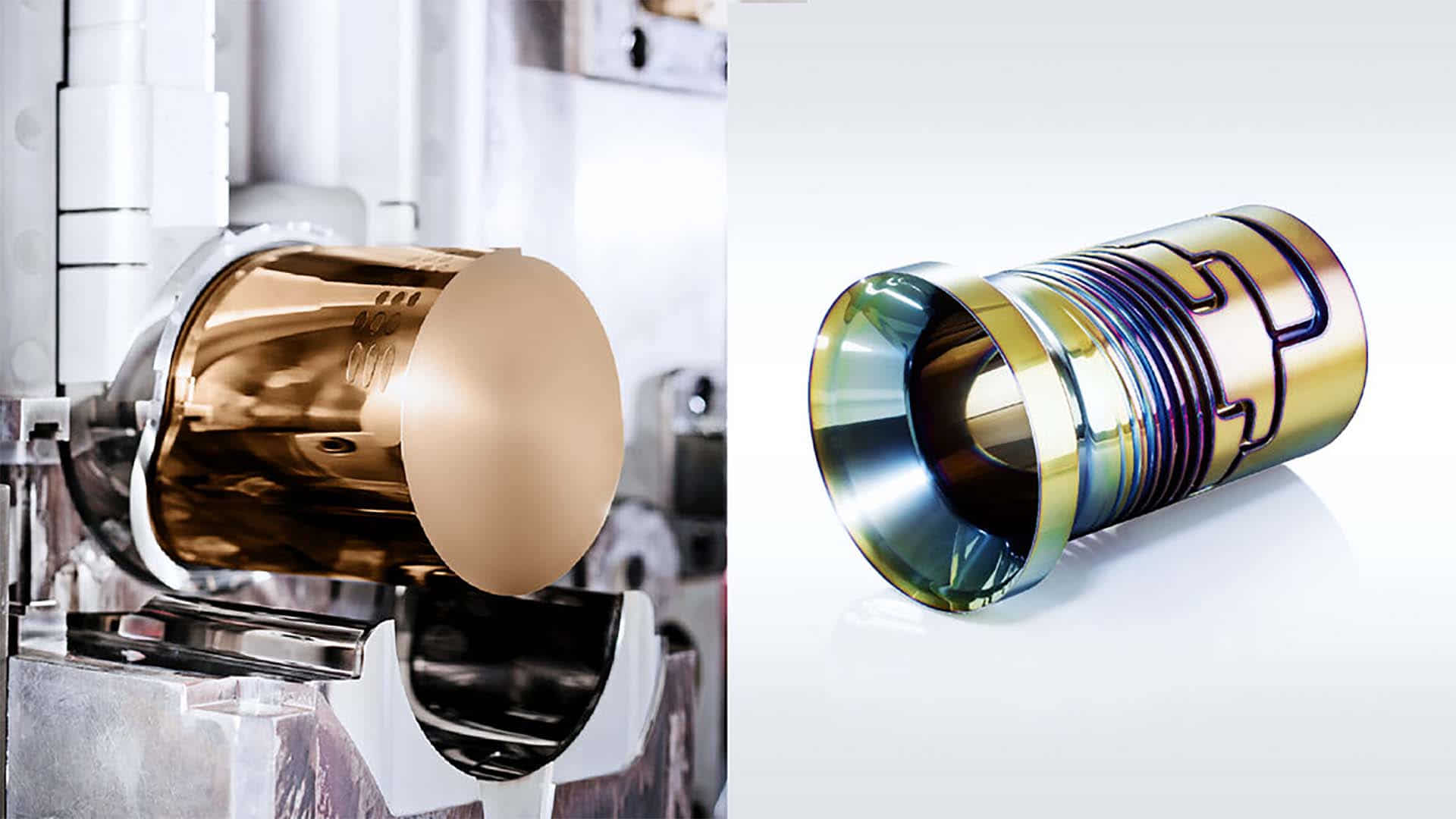

A further Oerlikon Surface Solutions division technology brand also attended the K 2022, with Oerlikon Balzers presenting BALINIT MOLDENA, a new coating for the injection molding process, and the extrusion of filled polymers with outstanding abrasion and corrosion resistance. In addition to all these, technologies for manufacturing nonwovens and sustainable filtration applications, and state-of-the-art systems for recycling plastics were also included at Oerlikon’s stand.

The company’s total solutions in an audiovisual 4D experience

Besides product and technology innovations, Oerlikon offered a diverse accompanying program at the K 2022. Visitors to the stand were shown the company’s total solutions offering in an audiovisual 4D experience. Furthermore, thanks to the trade fair’s close proximity to the Oerlikon Barmag site in Remscheid, existing and potential customers will also be offered an insight into one of the world’s largest manmade fibre R&D centres.