NIST Database, called “NIR-SORT”, containing the molecular “fingerprints” of different kinds of fabrics, will enable more rapid and efficient sorting of textiles and clothing. According to the Environmental Protection Agency (EPA), in 2018 around 85% of used clothes and textiles headed to landfills and incinerators, wasting precious resources and polluting our environment. It is stated that one reason is that recycling can be more expensive than landfilling, so companies have little incentive to recycle. To help solve this problem, researchers at the NIST (National Institute of Standards and Technology) have developed a free database available to download at the NIST Public Data Repository.

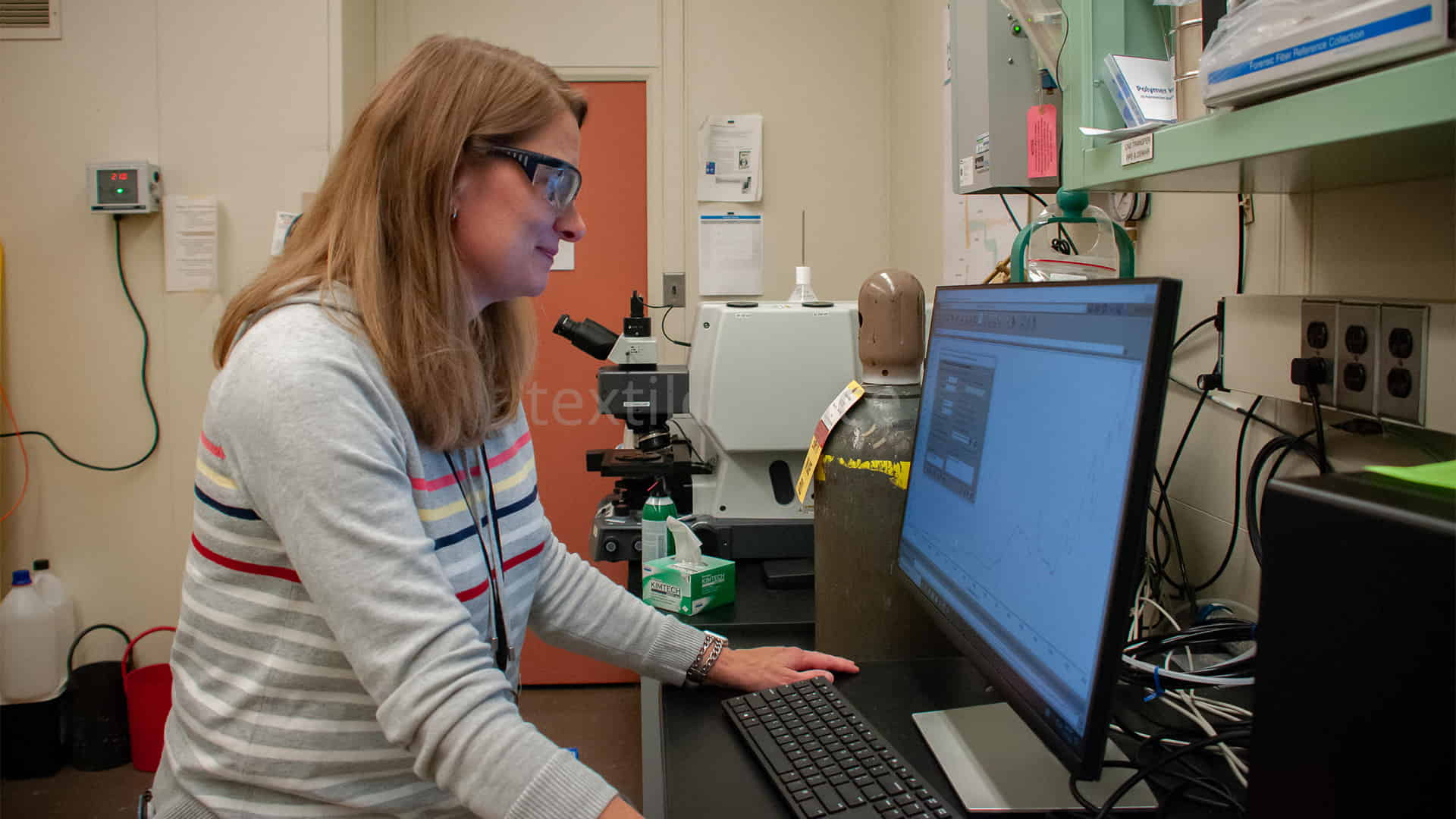

Amanda Forster, a NIST materials research engineer leads the NIST project focused on keeping end-of-life textiles in the economy, a process called textile circularity. She said that this reference data will help improve sorting algorithms and unlock the potential for high-throughput sorting, which requires less manual labour and noted that should reduce costs and increase efficiency, making textile recycling more economically viable.

The NIST Database contains 64 different fabric types and the NIR fingerprints they produce

The problem of textile waste has been growing in recent years. One reason is seen as fast fashion, a business model that has companies churning out large volumes of inexpensive, trendy clothes that are often quickly discarded. New types of textiles, blended textiles, and incomplete or inaccurate labeling also pose significant challenges when it comes to sorting textiles at recycling centers.

At those centers, workers sort clothing using handheld devices that shine near-infrared light. Those devices measure how much of the light passes through or scatters off the fabric, producing a unique pattern — a sort of fingerprint that can identify the type of fibers in the clothing. This technique, called near-infrared (NIR) spectroscopy, can also be used in automated conveyor belt systems. However, current techniques still require a lot of manual labour.

In recent years, recycling equipment manufacturers have increasingly used machine learning and artificial intelligence to improve their sorting algorithms. To train these algorithms, they need high-quality reference data. At this point, NIST’s database plays a significant role.

Called the Near-Infrared Spectra of Origin-defined and Real-world Textiles, or NIR-SORT, it contains 64 different fabric types along with the NIR fingerprints they produce. The database includes pure fiber types, such as cotton and polyester; blended fiber types, such as spandex blends; and real-world fabrics taken from thrift stores. Manufacturers of NIR scanner systems can use this database to train and test their sorting algorithms and improve the performance of their products.

“AI can help make the decision-making process more accurate”

“The difficulty comes in when fibers are similar, like cotton or hemp. That means that the near-infrared signal is similar. The same is true with a cotton and polyester blend. Is this a new fiber or a blend of two or more fibers?” said NIST research chemist Katarina Goodge, who led the development of the database. Goodge pointed out that AI can help make the decision-making process more accurate.