The printing hall had a very lively atmosphere and heavy visitor traffic at the ITMA Barcelona. Konica Minolta, one of the important exhibitors of this hall, exhibited the Nassenger 10 digital inkjet textile printer at their booth and shared their comprehensive solutions for the textile industry with video presentations. The company performed a demonstration with Nassenger 10 every 15 minutes during the exhibition and presented the printing performance of the machine to their visitors.

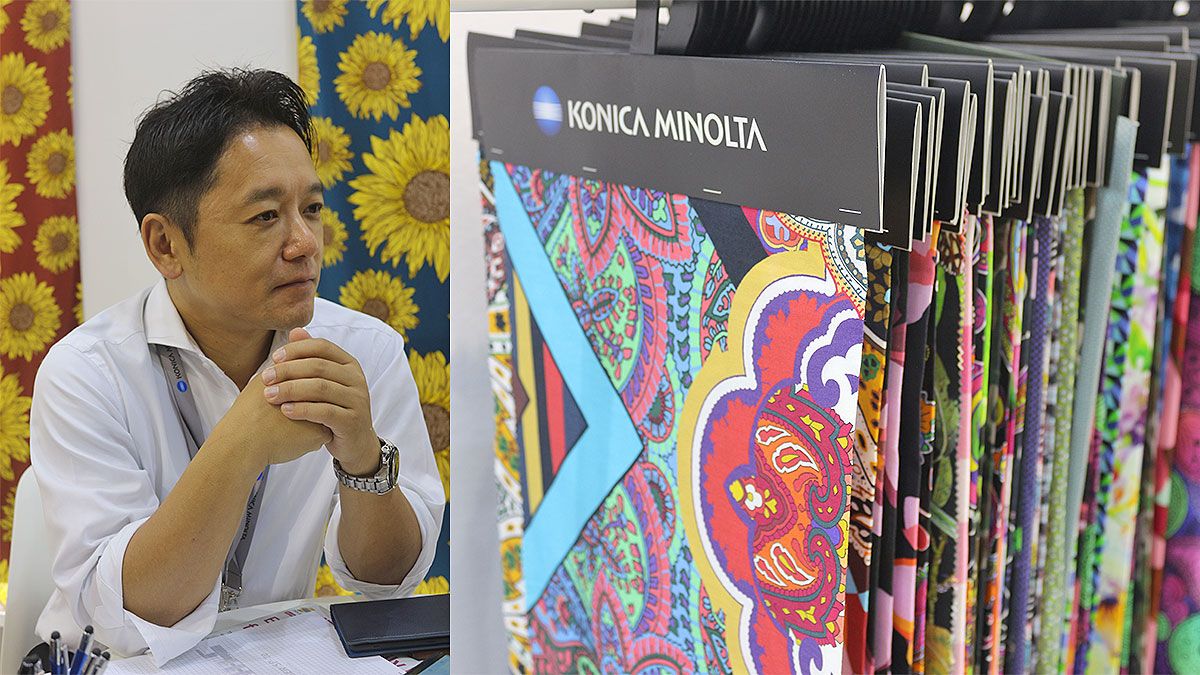

Konica Minolta IJ Textile Europe S.r.l. President Seiji Nakashima informed Textilegence about their participation in the exhibition. Nakashima, who stated that they took part in ITMA with the slogan ‘Rethink Textile’, said that they were pleased with the visitor interest. Nakashima said; “In general, we have visitors from all printing markets, but India, Pakistan and Bangladesh markets are prominent. The transition from traditional printing to digital printing is very important for these emerging markets. I must also express the interest of textile manufacturers hailing from Turkey. Some of these visitors are already our customers and some are planning to invest for the first time”.

Stating that the exhibited Nassenger 10 gathers a lot of interest in the Turkish market, Nakashima said that already 10 machines are installed in this market in past 3 years and that successful performance is obtained.

Nassenger 10 becomes an almost new model with continuous upgrades

Expressing that Konica Minolta attended ITMA with innovations and upgrades, Seiji Nakashima informed that Nassenger 10’s software is been upgraded continuously, even now, and also on currently existing printers in the field. Nakashima; “We first launched the Nassenger 10 high-resolution, high-output and high-speed scanning textile printer at ITMA 2015 in Milan. With the updates and improvements we have made in the intervening time, we can say that Nassenger 10 is almost a brand new machine”. Nakashima mentioned the following improvements;

“With software upgrades and hardware innovations, downtime and high stability have been achieved, especially in production. The same print quality can be achieved from the beginning to the end. We have a system for misprint compensation. With this, the empty nozzle compensates, and proprietary image processing technology solves problems that cannot be avoided even before at scan printing. Printhead cleaning and empty nozzle detection systems for stable production provide cost and time advantages for printers”. Nakashima pointed out to the long printhead life as another advantage that Nassenger 10 customers have; “Many of our customers have told us that they have not changed printheads for at least 2-3 years. This field-proven head stoutness is one of the most important reasons for choosing Nassenger 10”.

Technical features

Mr. Nakashima reminded that Nassenger 10 reaches speeds of 230m2/hour, 450m2/hour and 580m2/hour in 3 different standard production in 8-color printing and 990m2/hour in “draft mode”, however due to its stable quality, some customers are even using this mode for their production. Seiji Nakashima stated that the main development is efficiency. Nakashima argued that several brand have their machines with print speeds of 1000m2 per hour in their catalogue, but this does not happen in actual production in the field;

“Increasing productivity is more important for printers, rather than unrealistic speeds in actual production. Nassenger 10 has improved production efficiency as well as improved production speed in 10 different print modes. This means that the machine can be operated without problems for almost 24 hours. It doesn’t stop because of any problem with the heads. The feedback we receive from our machines, which have been installed in the market for more than 3 years, confirms this information”.

Emphasizing that Nassenger 10 machines only stop when work is finished or when fabric change is required, Nakashima said; “If you started the machine by preprograming all designs and patterns while a print job was in progress, Nassenger automatically identifies it and makes the pattern change. There is no stopping and no loss of time”.

Turkish printing market’s potential is high

Emphasizing the high potential of the Turkish printing market; Nakashima said that the country had some economic and political problems; which affected the industry and investments. Nakashima concluded his words as follows; “Despite the fluctuations in exchange rates and uncertainty^; the Turkish printing market has been very conscious of investment compared to the past. The meetings we held during ITMA show us that the Turkish printing industry has preferred digital solutions for new investments”.