The Montex XXL 7m wide width stenter designed for technical textiles and non-woven industries to be highlighted at INDEX’17

A. Monforts Textilmaschinen will be highlighting its recently introduced 7m working width Montex XXL stenter at INDEX’17 in Geneva, 4-7 April 2017 on Booth 4035. The XXL wide width stenter has been specifically designed to meet demand by the technical textiles and non-woven industries, such as, for example, geotextiles for finishing wider width fleece and fabrics.

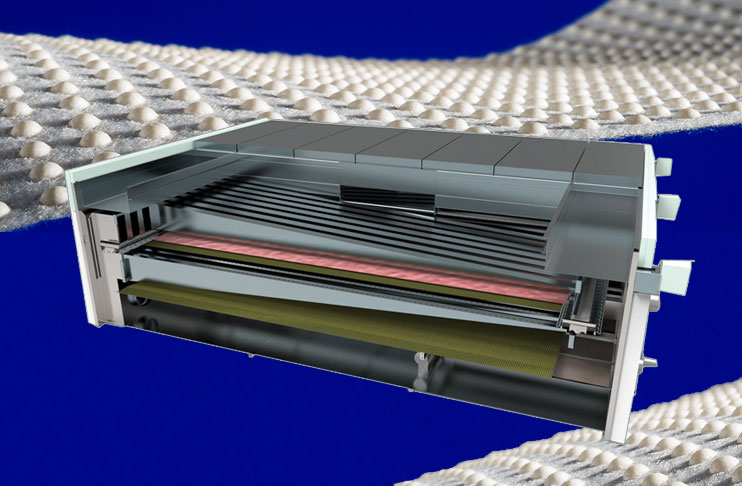

Heat distribution is a key engineering element of the Montex XXL requiring even temperature distribution over the full 7m width and the distance from the fabric entry into the stenter through to the fabric exit.

Monforts CADstream nozzles for wide width working have been computer designed and ensure the best even temperature distribution; and the highest homogeneous airflow over the full width.

The new Montex stenter is also equipped with the proven Monforts TwinAir system; for individual adjustment of lower and upper nozzle pressures.

For heavier weight fabrics a supporting belt can be fitted between the upper and lower nozzles of the stenter; for mark-free fabric transport through the stenter.

Monforts commitment for sustainability and energy savings

In keeping with Monforts commitment for sustainability and energy savings; the XXL features the integrated heat recovery system; fitted as standard on all new Montex stenters.

The system comprises a compact, air-to-air heat exchanger, which is installed within the roof structure of the stenter. The heat exchanger uses energy from the exhaust gas to preheat; up to 60% of the incoming fresh air entering the stenter.

Dependent on the production conditions, this provides energy savings of 10-35%.