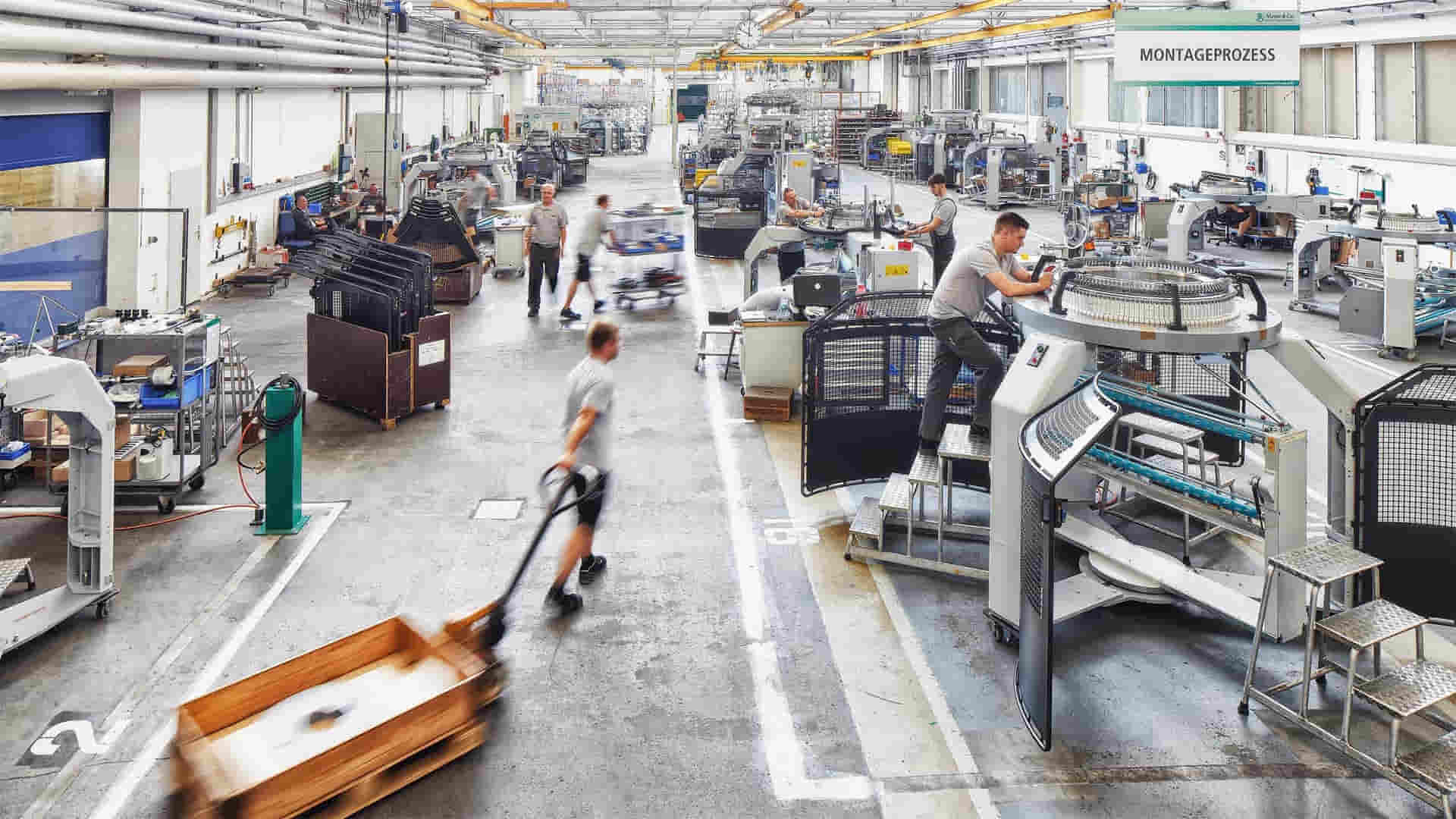

The textile machinery manufacturer Mayer & Cie. will be at ITMA 2023, for the first time with both of its business units: circular knitting machines and braiding machines. The company will focus on similar features in both areas: sound machines fitted out with solutions that make braiders and circular knitting machines more efficient, longer-lasting and thereby more valuable at its stand E101 in Hall 2. The solutions range from upgrade kits for individual machines and innovations to reduce waste to digital solutions that improve the customer experience.

Mayer & Cie. CEO Benjamin Mayer saying; “With our ITMA presentation we show why and how investing in Mayer & Cie. machines is worthwhile and pays long-term dividends,” and noted that last but not least they thereby also respond to the desire for more sustainability in the use of resources.

New developments on circular knitting machines from Mayer & Cie. at ITMA

Mayer & Cie. will be exhibiting three circular knitting machines at ITMA: the revised OVJA 2.4 EM and Relanit 3.2 HS and the new three-thread fleece SF4 3.2 III. All three serve classical uses and, except for the new SF4-3.2 III, are established in the market.

The OVJA 2.4 EM, currently accepted as one of the most productive machines in its class, knits double jacquard with electronic individual needle selection in the cylinder and double fabric with weft thread. Spacer fabric has now been added to its portfolio.

For ITMA 2023 Mayer & Cie. has fitted out the existing Relanit 3.2 HS with improved yarn guides. It has a needle with an optimised hook and tongue shape and a pre-determined breaking point to improve safety at higher output. The new sinker is another feature of the Relanit 3.2 HS. It makes the machine run smoother and reduces wear and tear. Mayer & Cie. Head of Product Management Axel Brünner says that many knitting mills all over the world already swear by Relanit machines and states that for them and new customers, they are working on further improvements to their bestsellers.

With the third machine on show Mayer & Cie. is addressing a major trend in the clothing industry. The SF4-3.2 III for three-thread fleece, especially for leisurewear, both in pure cotton and in blends, is in great demand. As Axel Brünner explains, “In this new machine we combine our tried and trusted MBF 3.2 and components of our MFC 3.2 that have proved advantageous in the Chinese market.”

Brisk braiding: Extra-speed machine for textile braid

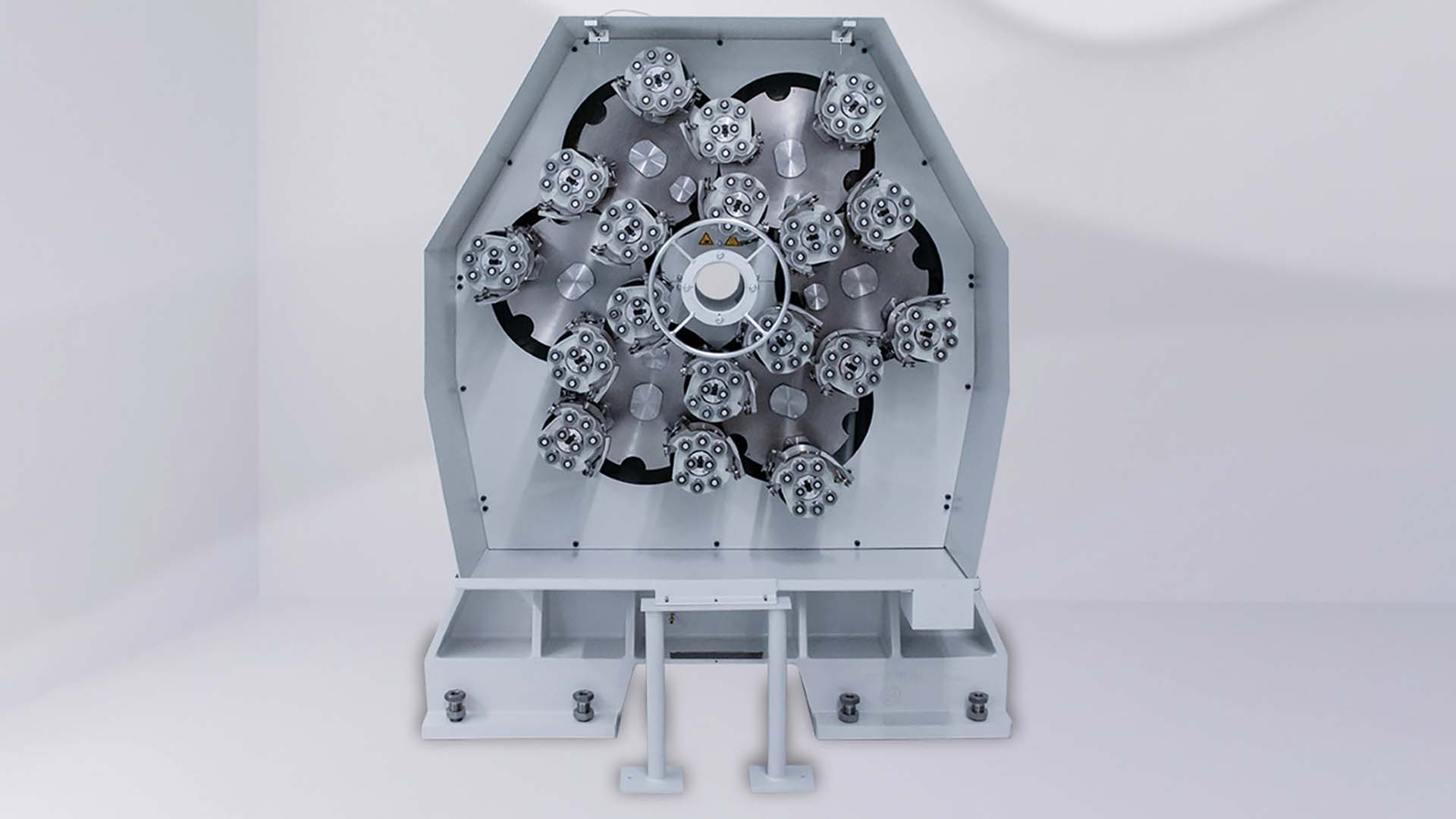

The MR-15/18 C/Single Deck braider on show at ITMA 2023 is designed for textile braiding. It comes with the new capstan wheel pull-off that is especially suitable for smaller-diameter hoses with textile braiding. The SpeedBooster upgrade kit delivers more speed and up to ten per cent more output.

Smart upgrades for long, efficient machine life

Longer, faster and with even greater precision, upgrade kits enable customers to benefit from technical progress at Mayer & Cie. The upgraded portfolio ranges from speed boosters to special plaiting and laying equipment. Another newcomer is spare parts with upgrade kits customised for individual machines. They deliver additional production and planning safety. Upgrade kits, like all known spare parts, are available from the web shop. Along with an easy-to-use search function, the web shop provides smart additional functions and includes the new loyalty programme my.loyaltyclub with attractive discounts.

Visitors to the company’s booth will also be able to get information about its smart functions: knitlink, knithawk and Control 5.0. The new knithawk recognises and identifies knitting faults fast during the knitting process, switching the machine off automatically. knitlink, the platform that links the manufacturer, representatives and customers, is IIoT-based (Industrial Internet of Things) and the central location for all machine data that every customer can use to record and evaluate the performance of his machines. Circular knitting machines with Control 5.0 are IoT-enabled and can inter alia be operated from mobile devices, so the knitter no longer needs to be physically at the controls.