One of the leading suppliers of complete spinning lines with the components and digitalised solutions that optimise performance in the spinning process, Marzoli will present its latest innovations at ITMA Asia + CITME between 12-16 June. Participants who will visit the company’s H8 – D50 stand will be able to closely experience Marzoli’s digital and artificial intelligence solutions as well as solutions for the nonwoven segment.

Marzoli serves all sizes of project, from a single machine to a complete spinning mill and its other solutions are staff training and organisation of maintenance activities; turnkey solutions and support in financing activities; business plan development; automation level analysis and project management. With all these solutions, Marzoli is among the leading global partners for the textile industry.

The products to be exhibited at the Marzoli’s stand include the Draw Frame DFR1. With its 1000 m/min production and low CV%, Draw Frame DFR1 has an important position in terms of production capacity and yarn quality, and offers easy use. In addition, it provides advantages to the user with high reliability, flexibility and low operational costs.

Marzoli will present smart solutions for plant management at ITMA Asia

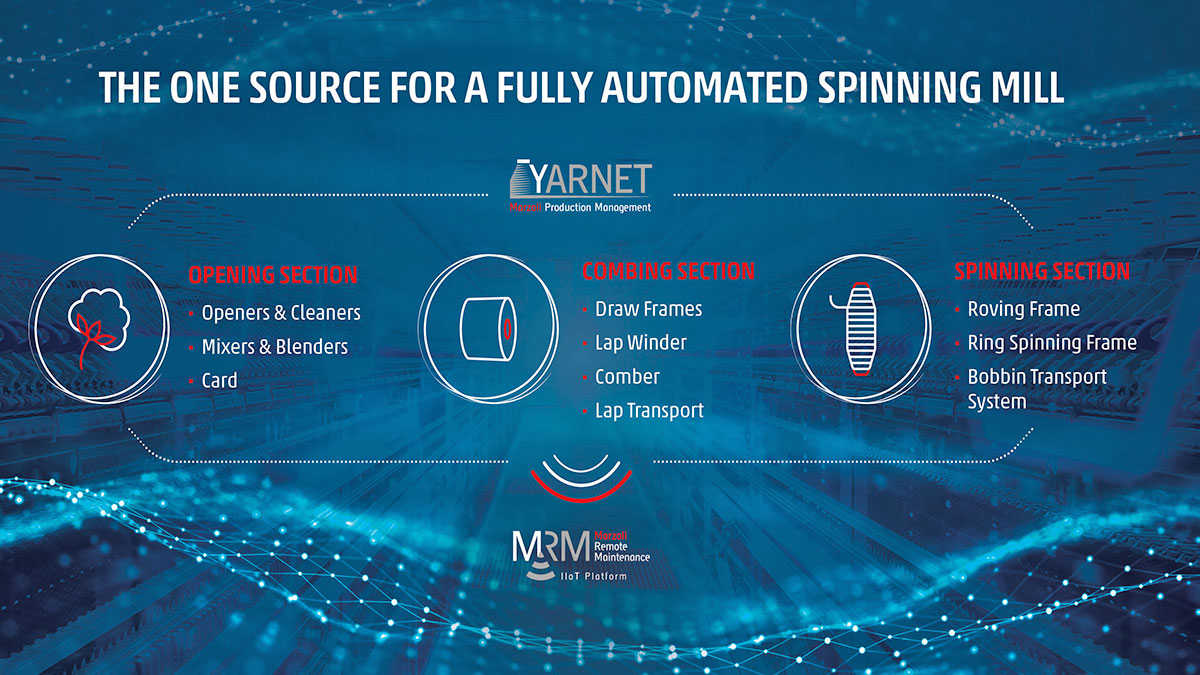

Marzoli develops the latest digital technologies that offer smart solutions for predictive maintenance, remote control and plant management. In this context Marzoli’s latest innovation, MRM (Marzoli Remote Maintenance) will also meet with the visitors at the fair. MRM is the world’s first patented software platform able to analyse Big Data generated by machinery processes and also continuously monitor mission-critical operations. This software platform provides a reduction of machine downtime, a longer useful life of parts, and more timely and effective maintenance.

Users can enable integrated management with YarNet, innovative software with which they can easily manage the entire Marzoli spinning process directly from their computer. Thus, every machine in a plant can be easily monitored and it becomes a true value-added technology for customers aiming to maximize productivity and profitability.

Performance in spinning mills increases with artificial intelligence

Marzoli also uses artificial intelligence technology in its developments and one of the products that Marzoli will exhibit in this field is Brain Box. Developed entirely in-house, Brain Box is included in the company’s solution portfolio as a patented Marzoli software with an integrated APP, which significantly improves plant performance. As a result of the tests, Brain Box has been confirmed to be able to increase productivity by 5.5%, efficiency by 8% and energy saving by 1.5%, and the installation of Brain Box is carried out quickly and simply. For the process consisting of only four steps, sensors are first installed on each machine. After the sensors are connected to the Brain Box and the APP is downloaded, finally the monitoring function is activated to detect any problems.

Another solution from Marzoli in this area, TAOMAPP, brings a new and innovative approach to cotton analysis, in which the trash level inside the cotton is accurately determined through photographs taken by a smartphone. Based on ultra-high resolution image recognition techniques, TAOMAPP quantifies results on the Marzoli Trash Index.

Developed with Marzoli software platforms as an effective tool to analyse cotton’s trash content to optimise machinery set up, Trash Analyzer can be applied wherever there is a flow of material in a pipeline.

One of the prominent topics at ITMA Asia is the circular economy

The circular economy, embracing sustainability, recycling and other green disciplines, will be another important topic at ITMA Asia. Focusing on continuous innovation in the mechanical regeneration of textile fibres for many years, Marzoli continues to contribute in this field.

Marzoli General Menager Cristian Locatelli, said that for Marzoli, developing and adopting green technologies means carefully balancing business needs with environmental sustainability. Arguing that circularity through fabrics regeneration is creating a synergetic value chain that benefits all stakeholders, Locatelli commented; “The new paradigm of a circular fibre supply chain will accelerate learning and development of know-how pushing innovation and opening up new potentials”.