Oerlikon Polymer Processing Solutions Division of the Oerlikon Group, providing manmade fibre plant engineering and flow control equipment solutions, is coming to bring its latest technologies to the Turkish market. The company will inform its visitors about its solutions and technologies at the Tekstil Servis booth in Hall 3, no. 313 at ITM 2022 to be held in Istanbul on June 14-18 after a long hiatus. The company’s concrete concepts in sustainability as well as advantageous developments from yarn to nonwoven fabrics will be exhibited at the Oerlikon booth throughout the exhibition.

Oerlikon’s focus at ITM 2022 will be on total solutions from melt to yarn, and fibres through to nonwovens. Such concepts offer a harmonized technology that guarantees the high quality of the yarn by procuring all process steps from a single source. Another topic to be focused on will be sustainability. Here, textiles, biopolymers and circular economy, especially in manmade fibre yarn manufacturing, as well as mechanical and chemical technologies for recycling of bottles come to the fore. Oerlikon Polymer Processing Solutions offers concrete concepts with partners and subsidiaries such as Oerlikon Barmag Huitong Engineering (OBHE) and Barmag Brückner Engineering (BBE), in this regard.

Oerlikon Regional Sales Director Oliver Lemke said that Türkiye is an extremely active market and disclosed; “Our customers are hugely interested in factory projects that comprise everything – from the in-house polycondensation system through to the textured yarn, the accompanying automation and corresponding digital solutions. Basically from Melt to Yarn and beyond.”

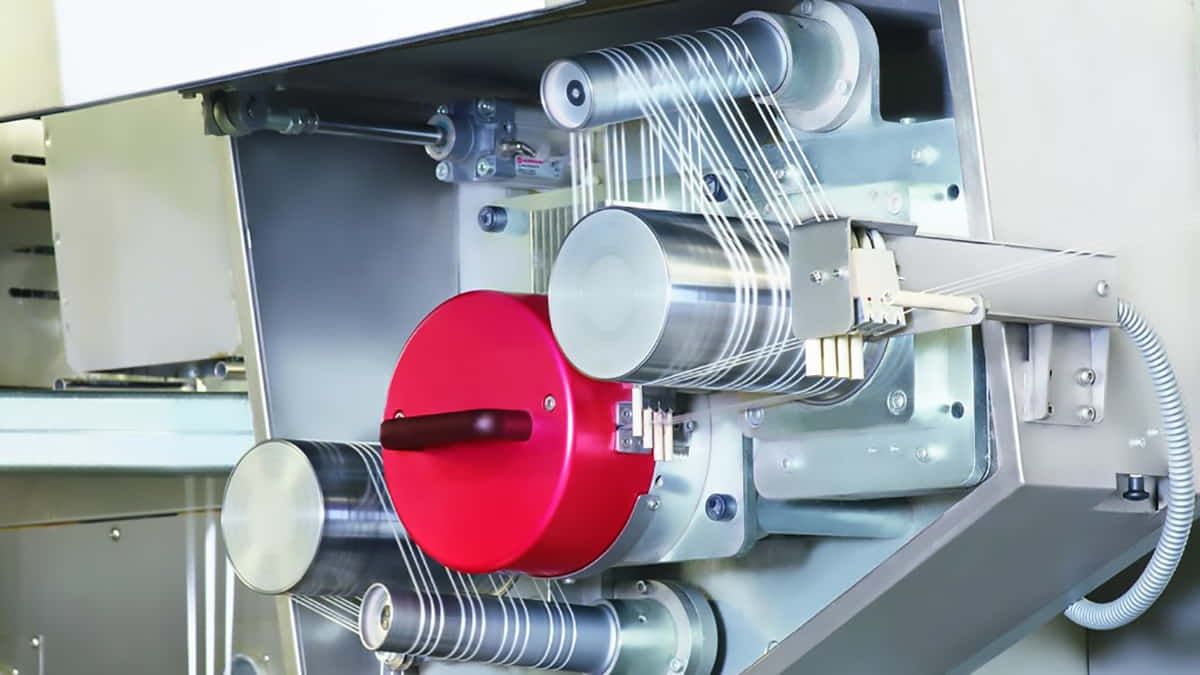

It is possible to tangle BCF yarns with Oerlikon Neumag RoTac³

The demand for high-profit yarns is noticeably rising with the trend of high-pile carpets and carpets for outdoor use. The thick BCF yarns made from PP, PET and PA6 required can be tangled using the RoTac³. All three filaments are jointly fed through a tangling opening in the RoTac³ and then tangled during the spinning process. BCF Sales Director Arnd Luppold explains the advantages of spinning with RoTac³ as follows; “BCF yarn manufacturers can now also use the RoTac³ for yarns of up to 6,800 dtex. They not only benefit from energy savings due to lower compressed air consumption and considerably more even tangling knots, manufacturers can also respond more flexibly to market requirements and hence expand their product portfolio.”

Tangling knots can be set much more evenly with the RoTac³ than other tangling units, even at high production speeds. This, preventing frequent tangling glitches, ensures better yarn quality and has a positive impact on further processing. The result is a visibly more even appearance on the carpet. Furthermore, compressed air consumption is reduced by up to 50 percent, depending on yarn type. The 3-in-1 plying package is optionally available for the BCF S+ and BCF S8 with RoTac³ systems and can also be retrofitted on request.