Allegro and Storm Duo models that will be exhibited at Tetaş’s ITM booth, Kornit Digtial underlines the growth target in the Turkish market. Allegro will also be the main part of the microfactory that will be found at Tetaş booth. This microfactory will produce small gift items throughout the fair.

Tetaş, one of the important technology suppliers of the Turkish apparel and clothing industry, takes part in the ITM 2018 exhibition with the brands they represent, especially Kornit Digital. Hosting their visitors with a special concept in Hall 7 booth 710C and 711C, Tetaş will present textile machines and digital printing solutions in two separate sections. In the textile section of Tetaş booth; Shima Seiki knitting, Tajima Embroidery, Unitex circular knitting, Pegasus/Zoje Sewing and other solutions will be present. Tetaş Digital Printing Solutions, where visitors are expected to show a lot of interest, is at the centre of the booth area with Kornit Digital. Polyprint, Shima Seiki SIP and Roland DG solutions will also be available here.

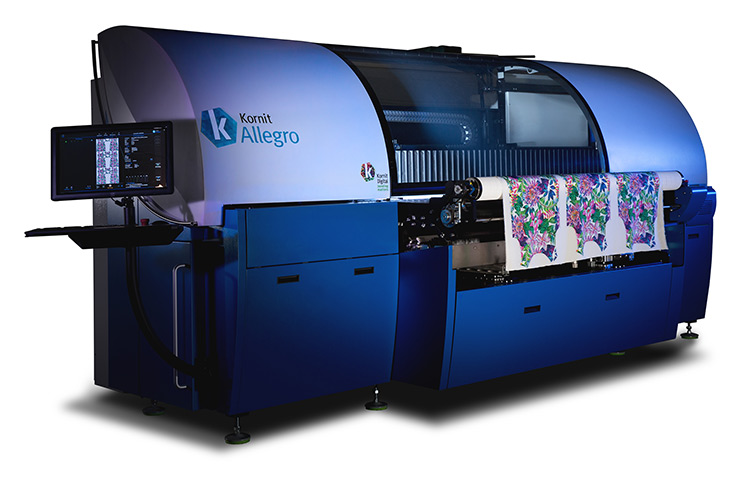

The solutions Kornit Digital has developed for different production demands will take an important place in the digital area of the booth. The industrial solution for direct-to-garment; Kornit Storm Duo is aimed at manufacturers of baby products, especially in Bursa market. The Kornit Allegro solution for roller printing (R2R) with the ability to perform all printing in one step with zero water usage will be the focus of manufacturers and brands looking for environmentally friendly printing solutions. Polyprint DTG (direct-to-garment printing) solutions meet the needs of entry level producers. Roland DG sublimation printer for polyester, which they have started to sell for the first time in the past months, will be presented with the printing paper and ink provided by Tetaş. Shima Seiki’s SIP textile printer of which the name is almost integrated with Tetaş in the Turkish market provides reactive printing for tricot / knitted products.

Allegro will be the heart of the microfactory

The Tetaş booth will have a different design to emphasize the innovative power of digital printing. Kornit’s Allegro model will use new neon inks for the pigment industry. A neon tent stand will be set up to make these neon coloured prints more distinctive. In this tent, visitors will be able to experience the print power of the Kornit machines in neon colors.

Allegro will also be the main part of the microfactory that will be found at Tetaş booth. This microfactory will produce small gift items throughout the fair. The integrated machines are as follows; Allegro (printing), Shima Cutter (single cut cutter with camera option), Zoe sewing machine (template machine), Tajima SAI (embroidery), Pegasus (sewing).

Oliver Luedtke : We are at a very well positioned point in the Turkish market

Providing information to Textilegence about Kornit’s participation at ITM 2018 with the booth of their Turkey channel partner Tetaş, Kornit Digital Europe GmbH EMEA Marketing Director Oliver Luedtke underlined the importance given to the Turkish market. Luedtke; “The growing number of Allegro and other direct-to-garment printing systems installation for the facilities in the Turkish market, shows us that we are at a very well positioned point in the Turkish market. In the near future we expect a significant growth in Turkey”.

Kornit’s Allegro is a unique roll-to-roll textile printer, based on patented NeoPigment Intenso inks. It is 1,80m wide, prints 100 linear meters per hour; and produces great, vibrant color based on a CMYK+R+G+Grey color model. Because it is pigment-based, it will print on all fiber types (cotton, polyester, wool, silk, etc.) with the same ink, and fabrics will be cured by a hot air dryer that is part of the solution. No steaming, no washing are required.

Style of production that does not require water

Oliver Luedtke stated that the printing systems of Kornit provide a great advantage to the installations; with minimal space and infrastructure requirements. In addition to the technical advantages of these systems, Luedtke also listed other outstanding features as follows; “One of the most important issues for Kornit is the style of production that does not require water. Thus, it is possible to make an environmentally friendly production. Our solutions, especially at Kornit Allegro, offer investors the opportunity to enter profitable areas that have never been possible before. At this rate, the return on investment costs can be much faster.”

ITM is accepted as an international fair according to Luedtke; and he shared his expectations visitor wise from Middle East countries; Russia, Eastern Europe and North Africa countries as well as Turkish visitors. Luedtke; “We are targeting especially apparel manufacturers (who mainly asking their printing job to outside); baby wear producers, screenprinters, embroidery producers; and printing people who are already in printing business with entry level machines and wants to grow up”.