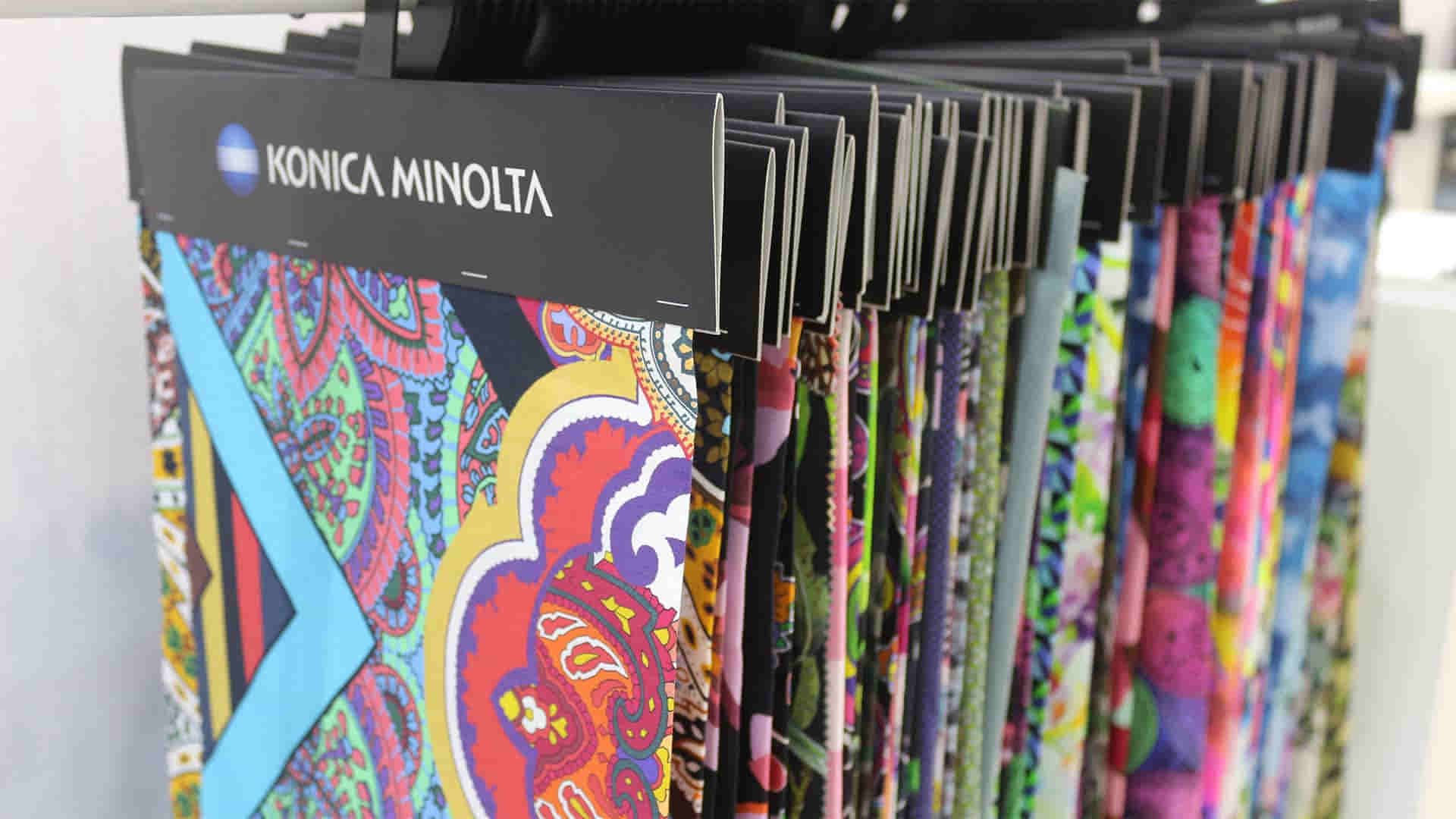

Konica Minolta, one of the leading brands in digital textile printing will showcase a series of solutions which will positively impact the environment like step process reduction and waterless applications at ITMA 2023 on June 8-14. In the company’s booth B301 in Hall 7, which will be an active part of the exhibition, the visitors are able to view and touch fabrics printed with the latest technological innovations.

Konica Minolta Director of Sales IJ Textile Gianluca Macchi, in a statement to Textilegence, said that the first ITMA exhibition after the pandemic is of great importance for the entire textile industry as it is an opportunity for companies to present their latest technological innovations, machinery, and materials in person. He added that it also represents a symbol of recovery for a sector severely affected by the pandemic and continued: “For us, it will be an opportunity to present new products and technological innovations that are sustainable and have a low environmental impact. The pandemic has accelerated the need for technological innovations and sustainable production processes in the textile industry. ITMA is the best opportunity for companies to present their solutions to meet these challenges and demonstrate their commitment to environmental sustainability.”

“Konica Minolta proved itself as a sustainable corporation”

Reminding that sustainability will be the central theme at the upcoming ITMA 2023 in Milan, where we will focus on environmental, eco-toxicological and economic sustainability, Gianluca Macchi mentioned that they proved itself as a sustainable corporation again and again. He stated that Konica Minolta was included in the list of the “2023 Global 100 Most Sustainable Corporations in the World” and received a GOLD-level recognition medal in the EcoVadis Sustainability Ratings for 2023, and said: “Furthermore our company was listed in the Top 5% of the most sustainable companies in its industry in the Sustainable Yearbook 2023 by S&P Global. This is the 13th straight year that Konica Minolta has been named in the Sustainability Yearbook demonstrating the company’s commitment to environmental sustainability. Our solutions are recognised worldwide as highly reliable and durable products; we develop our printers, inks and printheads using our proprietary technology. Thanks to these unique sources, we provide complete customer assurance through a unique interface and exceptional technical service.”

“For a more sustainable printing process, the focus should be on chemical innovations”

Gianluca Macchi pointed out that the printing process should be developed not only focusing on the mechanical process, but mainly with chemical innovations which should reduce, or even remove, certain steps of the actual printing textile process. He added that as a global multinational company, they offer their customers unique innovative solutions to optimize the current printing process and in this context, he emphasised the importance of their slogan: Rethink Textile Printing. He continued: “It is not just a slogan, but rather a way of living and thinking. The Rethink motto is an invitation not to stop doing things as usual, or as they have always been done, but to go further by pushing oneself to think outside the box, pushing always trying to innovate and change to adapt to the changing reality of the market. We are a company that has been in existence for 150 years and if we had not learnt to adapt we would not still be here trying to improve. It is a global campaign to ‘rethink print possibilities’ in the case of textile printing processes to look for and create environmentally friendly solutions that can create efficiencies in the printing and fabric creation processes.”

“In 25 years we increased productivity 500 times”

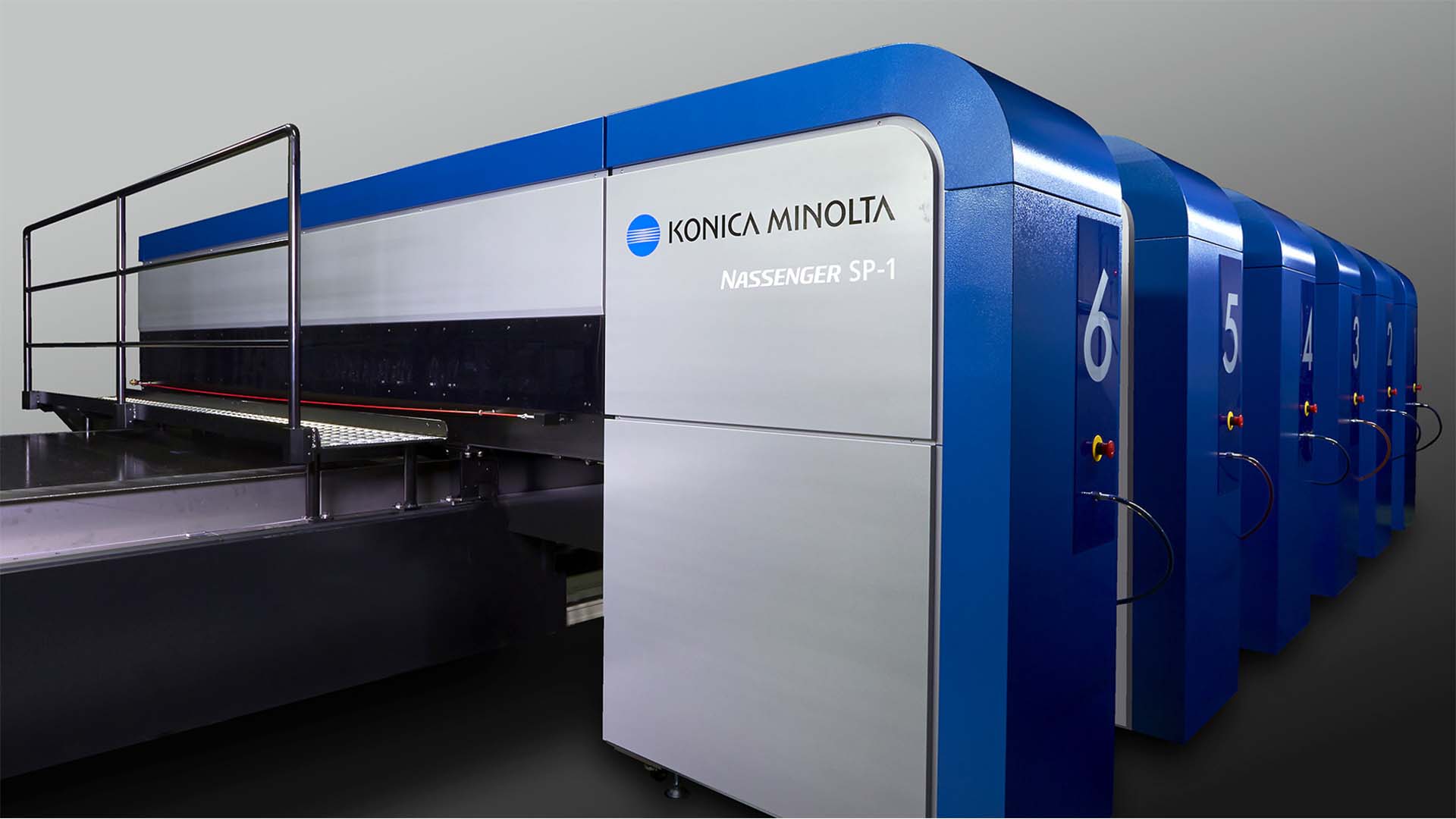

Gianluca Macchi, mentioning their R&D studies, said that they always looking for total customer satisfaction and during the last years they focused on further improving reliability and product customisation for various needs. He underlined that the concept of sustainability at the 360° level is the driver of their developments, noting that as a printing machine manufacturer, since the launch of the first Nassenger 1 in 1998, they increased productivity 500 times reaching a top speed of 60 m/min with Nassenger SP-1 keeping the maximum quality level in 25 years. He said that their R&D department is working in mid-terms on developing digital dyeing as well and concluded: “We invite all visitors who are looking for sustainable digital printing solutions to our booth at ITMA Milan. Konica Minolta along with our agent SPOT will also welcome all Turkish customers during the exhibition and be ready to discuss the advantages of our technologies.”