ITM 2022, one of the most important textile exhibitions in the world, will be the stage of Konica Minolta’s latest digital textile printing solutions. The company will exhibit the Nassenger 10 equipped with ‘full optional set-up’ and its two remarkable new developments at its booth 1211 in Hall 12, where it will perform 4 live printing demos a day on June 14-18. Konica Minolta Textile Sales Director Gianluca Macchi said that their booth will be side by side with the booth of their local agent, Spot Tekstil, at ITM 2022 and disclosed; “This will help both of us to maximize the quality and the efficiency of the services towards our existing and potential customers.”

Macchi stated that two different innovations await the visitors at the exhibition in his previous statement to Textilegence, and shared these details about their new solutions in the latest statement; “The technical innovation we will introduce at ITM 2022 will be the new pre-treatment ink, developed by KM (Konica Minolta) laboratories, which will allow our customers to innovatively change their actual production process. Our customers are able to make an in-line preparation through dedicated printheads instead of the off-line pre-treatment process. Secondarily, our technological innovation is a new workflow software using a smart APP developed by our R&D team. This will help our customers to monitor and control the full ‘textile flow’ of each single order.”

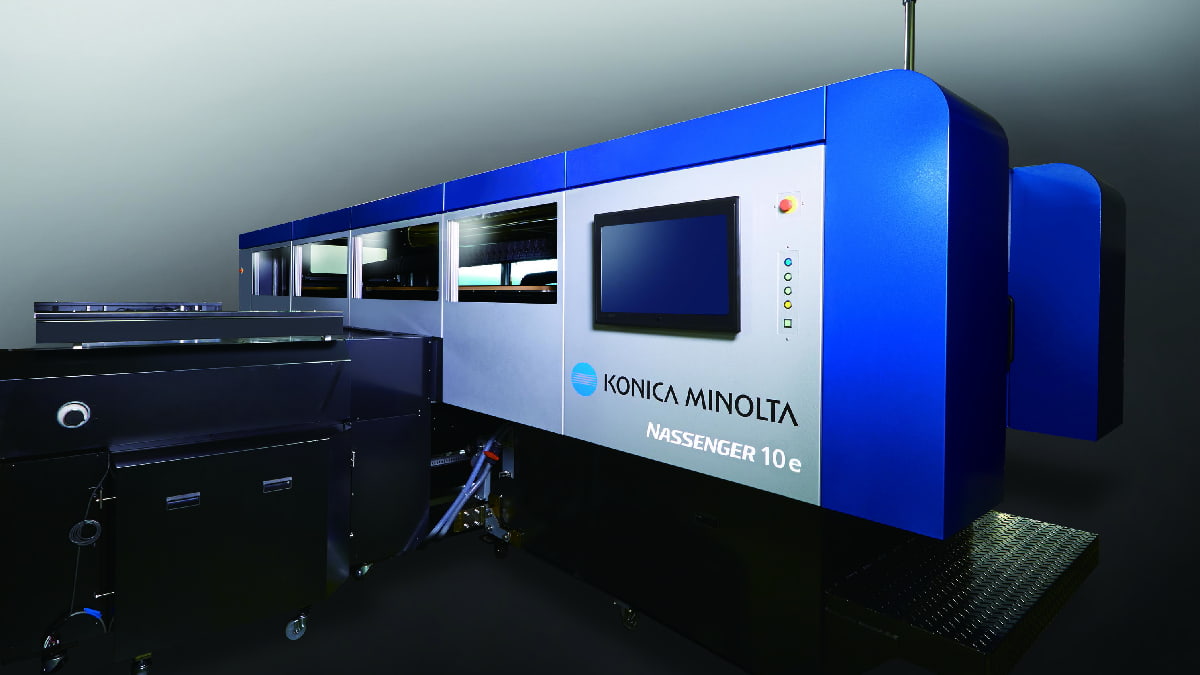

‘Full optional set-up’ with Konica Minolta Nassenger 10

Gianluca Macchi disclosed that Nassenger 10 digital inkjet textile printer will be at the Konica Minolta booth with its new options and features and explained the advantages of the printer as follows; “Nassenger 10 will be equipped with 81 Printheads and 9 colour lines. This set-up will allow us to use the pre-treatment ink in addition to 8 colours. This ‘full optional set-up’ has already proven its advantages towards those customers who decided to use our penetration ink to maximize the quality of their printing on their top quality fabrics.”

Macchi relayed that Nassenger 10, like all the other models of the Nassenger series (Nassenger 8 and SP1) is fully able to print all the different types of fabrics with maximum quality and performance. He explained that they can satisfy various needs and demands thanks to the flexibility of their accessories configuration, and a wide range of reactive, disperse, acid, penetration, pre-treatment inks.

“Users prefer higher quality products directly printed on the fabric instead of sublimation printing”

Gianluca Macchi, saying that Konica Minolta is constantly working on ‘green’ projects in order to help its users have a more eco-friendly production, underlined that all their products are fully Industry 4.0 certified and compliant. Macchi disclosed that as Konica Minolta, they are providing high-quality solutions for direct printing on textiles with various inks such as reactive, acid and disperse, with their main application in the apparel market. He remarked that the main users and retailers prefer higher quality products directly printed on the fabric instead of sublimation printing.

Macchi said that Istanbul has always been considered one of the central points of the world due to its strategic position and noted; “For this reason, we do believe ITM will be the perfect occasion to meet not only our Turkish customers but also other one coming from Pakistan, India, Uzbekistan, Greece, Russia, Sri Lanka, Bangladesh and other countries.” Macchi, stating that despite the effects of the pandemic, they achieved impressive results in both machinery and consumable sales, concluded his words as follows; “As of now we are quite worried about energy cost increase and raw materials availability. We are working in order to guarantee our customers high-quality products and services while keeping proper profitability.”