KARL MAYER GROUP, offering solutions for warp knitting, warp preparation for weaving and technical textiles, will host its visitors with its effective innovations in the face of changing conditions in the sector at ITMA 2023 in Milan. In light of the upheavals in the wake of current events, the industry leader spoke with its customers from all sectors and branches about their concerns, priorities and goals. During the discussions, five questions emerged as strategically essential and urgent and KARL MAYER GROUP will be presenting solutions and innovations in response to these customer questions at Hall 4 B119.

How to be profitable with increasing cost pressure?

The costs for materials, energy and transport services are exploding and are significantly reducing profits. Thus, many customers have started asking themselves “What can I do for my profitability?”. The answers of KARL MAYER for warp preparation are provided above all by a compact warp sampling machine with an even smaller space requirement and, for warp knitting, by the fastest three-bar tricot machine on the market with new functionalities. A warp knitting machine with magazine weft insertion for the production of technical textiles offers more efficiency by reducing weft yarn waste at high working width and speed. In addition, digital solutions open up new ways to increase profitability. One example is KM.ON’s Digital Production Management System for the digitization of processes, which, among other things, creates more transparency on the shop floor for the analysis and optimization of production with production-specific key figures available on a dashboard.

How can I keep my business running despite a skills shortage?

A glance at the KM.ON dashboard also saves a tour of the machine park and thus personnel capacities, an important plus point in view of the global shortage of skilled workers. The KARL MAYER GROUP’s Care Solutions division also has fewer personnel requirements in mind. The Care X-Tend Package, for example, provides an annual machine health check and remote service to ensure high machine availability without the need for the customer’s personnel. Visitors to the company’s booth will be able to reach more information about its other solutions.

How do I find new business opportunities with the existing cost pressure?

In view of rising costs, customers around the world are looking for new, lucrative business opportunities. The KARL MAYER GROUP also offers them support in this respect, for example with a double bar raschel machine that uses perfected jacquard technology to implement spacer designs with a high play of colors. The colorful 3D warp knitted fabrics offer particular potential for further applications in the apparel, furniture and automotive sectors. Sophisticated features for ADF models, which, among other things, enable the use of different STOLL technologies on one machine and thus more design variety, ensure new business in the flat knitting sector. In addition, an innovative machine will be presented that combines various fabric technologies and thus completely new textile constructions.

How to manage the increasing pressure to be more sustainable?

Environmental protection and resource saving are important success factors for customers today. A tricot machine with a focus on energy management and with pattern data transfer from the cloud instead of the material- and transport-intensive use of pattern discs takes this development into account. There are also sustainability optimizations in detail: a new function makes it possible to achieve considerable waste savings in weft yarn on the warp knitting with weft insertion, and on an ADF model from STOLL a package of targeted design changes resulted in lower energy consumption.

How to react to market requirements fast and flexibly?

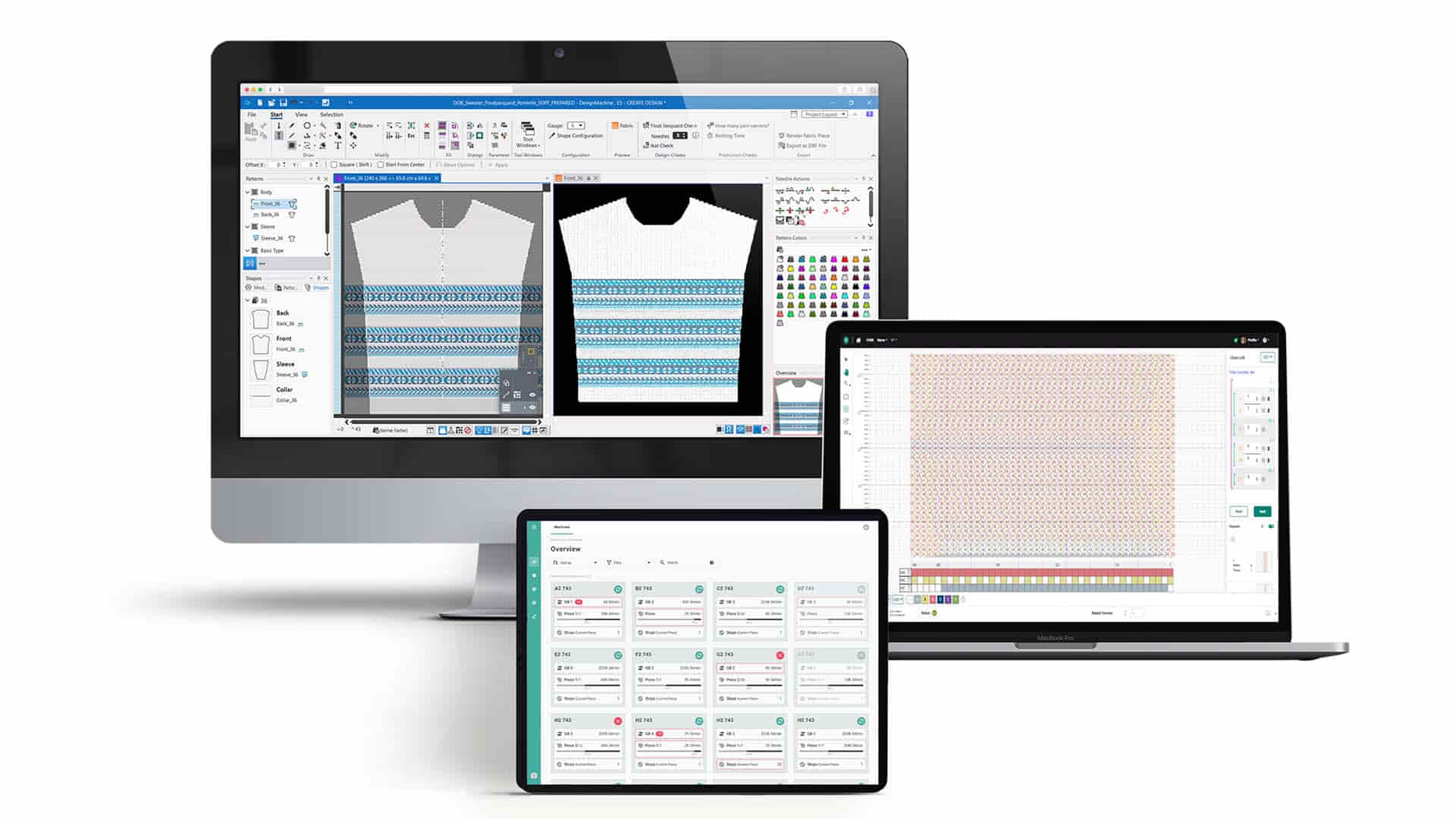

Data transfer from the cloud and ON pattern drive not only make tricot machines more productive and sustainable, but above all more flexible. STOLL’s fully fashion production also promises multiple benefits: Fewer additional fabrication steps mean less waste and more speed in the implementation of new products. In addition, the setup time on ADF models for pattern changes can be reduced with well thought-out constructive solutions and the design-to-market workflow in the flat knitting sector can be significantly shortened with CREATE DESIGN von KM.ON. Designers are able to simulate their designed textiles with the software at any time and become independent of the time- and resource-intensive development of physical samples. With the various STOLL technologies such as knit and wear®, weave-in® or intarsia, the ADF machines are also included in all-rounders. According to the motto ‘all articles on one machine’, various garments will be created on one and the same ADF model in front of the eyes of ITMA visitors in Milan.