Itema, one of the global brands of weaving technologies, presented innovative airjet and rapier weaving solutions to the Asian market at ITMACH India, held in Ahmedabad December 5-8, 2019. The Itema ITMACH India stand, which received much attention from the visitors, was also awarded with the ‘Best Booth’ award at the fair.

With their Rapier, airjet and projectile weaving technologies, India is a very important market for Itema. It is featuring numerous textile districts throughout the country and producing a wide range of woven fabrics. Over the years, the evolution of Indian weaving mills has been remarkable, due to the increasing introduction of the most modern and advanced weaving machinery and the ability to produce ever-more sophisticated fabrics, including technical textiles.

Itema is a trusted partner of many Indian weaving mills, from large textile conglomerates to smaller textile manufacturers, providing the most advanced and user-friendly weaving technology and real-time assistance, from the initial negotiation stage and throughout the whole machine life cycle. Itema is present in India with a fully-operational branch since 2002, counting more than 50 employees, with sales and after-sales teams, technical support and advanced repair centers in Mumbai, Coimbatore, New Dehli and Ichalkaranji to ensure the highest possible standard of weaving solutions.

Italy-based Itema shows their intense interest towards the Indian market through fair participations. Participation in ITMACH in Ahmedabad was especially important since the event constitutes a valuable opportunity to showcase the Itema weaving innovations and the company latest updates to the renowned Gujarat textile industry. Gujarat is, in fact, one of the largest textile Regions in India with several textile manufacturing companies and with the biggest cotton production in the country.

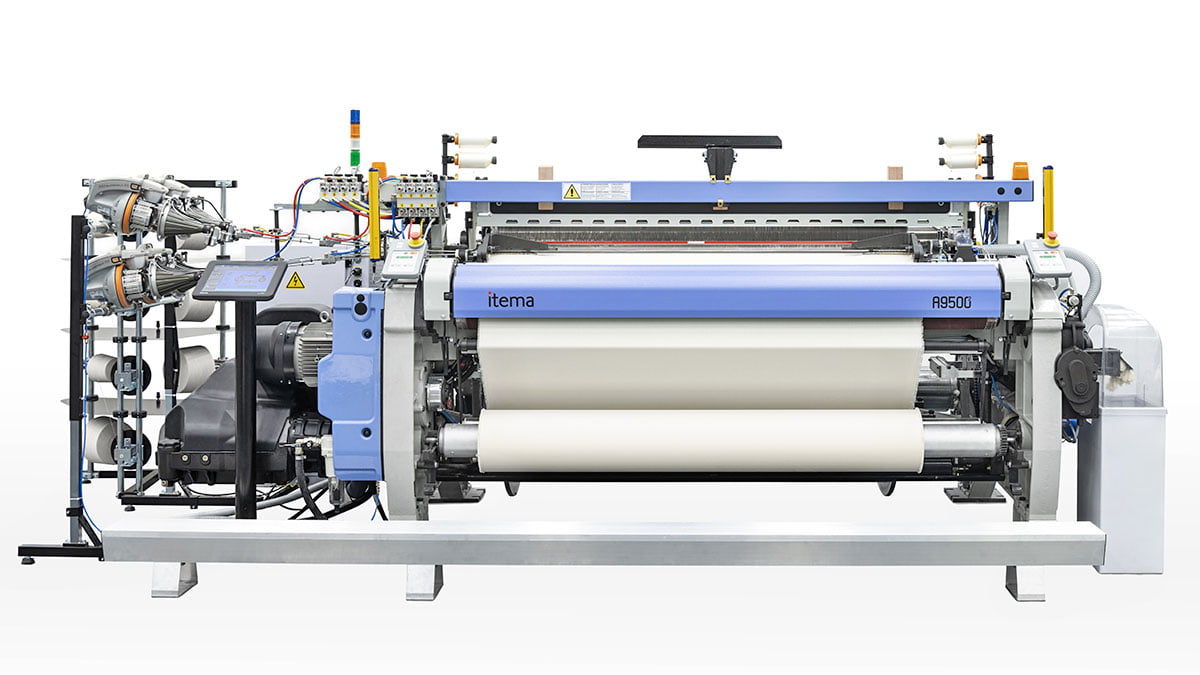

New generation airjet A9500-2 for high fabric quality and efficiency

ITMACH visitors showed great interest in the Itema booth in C1 to see weaving innovations and improvements. In particular, on the airjet weft insertion side – which is the most diffused weaving technology in the Region – Itema launched on the market during ITMA 2019 in Barcelona the Second Generation of its airjet model, the A9500-2. The A9500-2, the Second Generation of the Itema airjet A9500 and A9500p; sums up all the best features of its predecessors and further enhances machine performances, cost savings and textile efficiency.

The A9500-2 has a redesigned and optimized pneumatic platform to further improve weft insertion. The weft insertion cycle is significantly improved leading to a quicker system response when handling air load and pressure; thus guaranteeing minimized vibrations and higher structural reliability. Machine structure was revised to increase the air tank capacity ensuring superior textile performances even at the highest speeds.

The brand-new Bi-Power stretch nozzle which ensures perfect weft catching pick by pick, air consumption reduction and increased fabric quality; by keeping the weft perfectly straight in the fabric.

The brand-new heald frames SKYFRAME – Itema exclusive proprietary technology – made of aluminium and carbon and designed by Itemalab™ in cooperation with Lamiflex; thanks to the superior lightness and sturdiness; allow to run at the highest speeds without compromising reliability and resistance.

A9500-2 innovations for denim manufacturers

Gujarat Region is famous for the high concentration of denim weaving mills. Itema provides specific and unique-in-the-industry features to weave denim, and has innovations on A9500-2. The popular recent trend to weave stretch and super stretch denim fabrics with dedicated weft yarns inspired Itema to create; and patent the innovative BLC – Brush Lycra Clamp – nozzle to weave elastic weft yarns. Thanks to the BLC nozzle, the weft is held without movable parts to ensure superior fabric quality and reliability.

The Itema iREED® – developed by Itema in cooperation with Schoch (an Itema Group company starting from October 2019); is considered as the benchmark by the industry and significantly reduces the air consumption; whilst guaranteeing a higher efficient weft insertion. The new reed tunnel shape and new position of the relay nozzle optimize the air flow in the reed channel for a higher efficiency weft insertion. The Itema A9500-2, featuring these advanced innovations; ensures the weaver the possibility to weave faster, producing better fabrics and with a smarter usage of resources.

denim manufacturers experienced the rapier option at the Itema ITMACH India booth

On the rapier side, Itema is nowadays leading the denim market production on rapier weaving technology thanks to the prowess of its R9500-2denim. The R9500-2denim is supplied to manufacturers equipped with unique features for the denim industry.

iSAVER™ – the Itemalab™ mechatronic marvel which completely eliminates the weft and warp waste on the left-hand side of the fabric. Establishing a new benchmark in sustainable weaving; thanks to a reduction of raw material wastage and guaranteeing a significant money saving; iSAVER™ is gathering an exceptional interest from worldwide denim weavers and is already successfully running in some of the most famous denim mills.

The denim-dedicated SK UltraLight Weft Transfer System is another innovation. Thanks to reduced dimensions and lightweight rapiers and to the TLC-Triple Layer Carbon tape; ensures maximum textile efficiency and extended components lifetime.

iBOOSTER package, designed to literally boost machine’s performances, without compromising reliability. When running extremely fast, key rapier insertion system components are subject to considerable stress. Thanks to a deep materials study made by Itemalab™, in close cooperation with Lamiflex; Itema succeeded in developing new reinforced tapes, sprocket wheels and micro smart coolers to ensure extended lifetime. Moreover, a revolutionary detection system through sensors and digital intelligence allows a real-time control of the components health status.