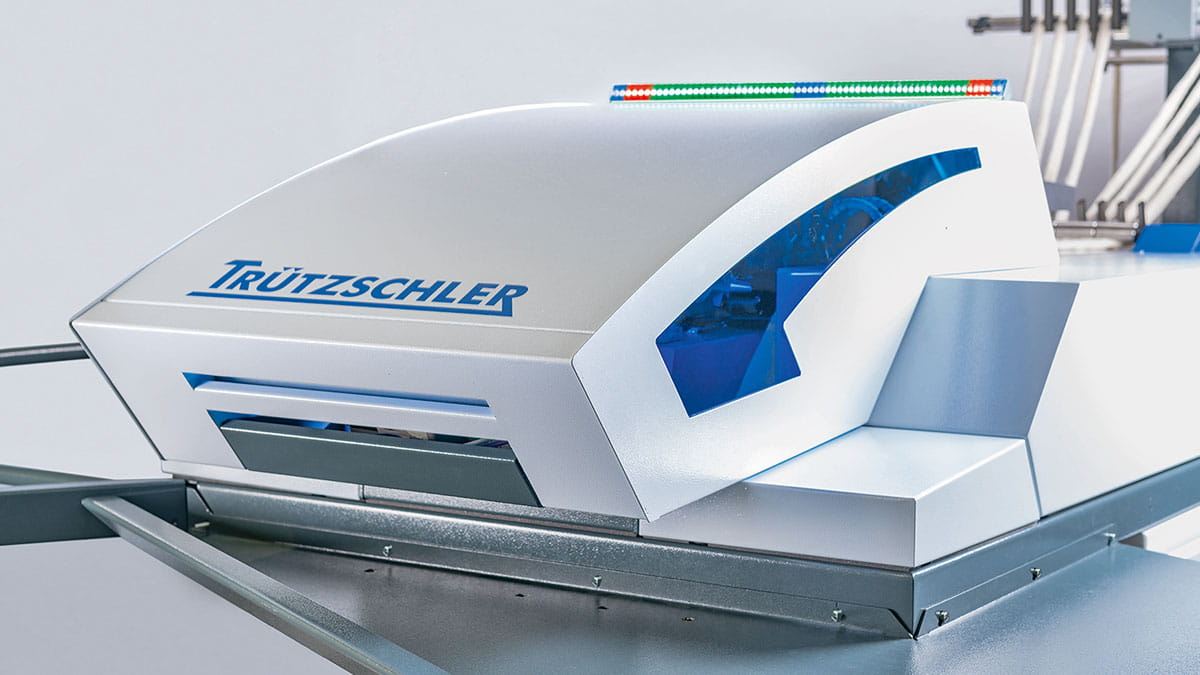

Based on the fact that light manages our perceptions and guides us, Truetzschler makes process management in spinning mills easier with the T-LED remote display system. The combination of multi-coloured LED lights shows more than ‘OK’, ‘Warning’ and ‘Fault’ notification. In particular, information about productivity and quality in the spinning mill can be read remotely at a glance thanks to this LED orientation.

A spinning mill is a great hall with spinning technologies, but there are long distances and many machines that need to be controlled operationally. It is important to understand and prioritize signals and information to minimize production disturbances as much as possible. Truetzschler makes this important communication process extremely simple with the T-LED remote display system. Thanks to the LED bar visible from both sides, machine operators can quickly and remotely read machine status using colour light signals and take the necessary measures immediately.

Process control at first glance

T-LED concisely displays the status of the respective machine and thus enables controlling an entire production process remotely – even with little staff. Intuitive human-machine interaction is provided by easy-to-remember lighting combinations. The employee knows instantly what the machine needs for further operation and can react accordingly. If, for example, he sees a yellow running light on the distant machine, he recognizes that new cans are needed. The operator immediately sets off with the empty cans.

Intelligent use of light for higher productivity

T-LED remote display system not only avoids unnecessary movements, but also helps to set priorities in order to maintain production and avoid downtimes. Errors and faults are displayed primarily so that one can react quickly. In addition, quality and productivity data, such as sliver count variations or fill quantities, can be displayed. With TD 10, for example, it is important to be informed about the quality limits of the CV value, while it can be useful to display can filling quantity at breaker draw frames. These different displays are freely selectable and can be adapted to individual requirements.

In automatic mode, specific information on certain parameters are clearly visible during regular production of the machine. Selectable display modes are; a % sliver count variation, can filling and CV % value. If there is a warning for a possible machine stop or a machine malfunction at short notice; the machine automatically switches to the corresponding status displays. In the process, T-LED can point out specific causes such as; sliver break in the creel with position display or empty can magazine.

T-LED: a component of digital transformation

Spinning mills today face the great challenge of finding qualified personnel for their machinery. Where there is a shortage of staff, the digital transformation should intervene. Truetzschler supports this transformation in addition to its digital solutions with intelligent machine concepts such as T-LED. These make it possible to keep production continuity at a high level even with few personnel.