Itema, one of the leading global providers of advanced weaving solutions, including weaving machines, spare parts and integrated services, will exhibit the most complete product portfolio to weave technical fabrics at Techtextil 2024 in Frankfurt on April, 23-26. The exhibition will represent an unmissable opportunity to discover all the Itematech weaving solutions and to discuss with the experts any weaving need. At Booth D24 in Hall 12, the Itematech representatives will introduce to visitors the whole Itematech weaving range and the latest advancements in weaving technical fabrics, in detail.

Recognizing the specificity of the technical textile industry, Itematech was established in 2019 with the aim to provide a comprehensive range of weaving solutions tailored to manage this complex fabrics in an easy yet efficient way. Itematech provides an ideal choice for weavers seeking for a partner able to offering a diverse weaving machine portfolio for producing technical fabrics, including Single Positive Rapier, Negative and Positive Rapier, Airjet and Projectile weaving machines.

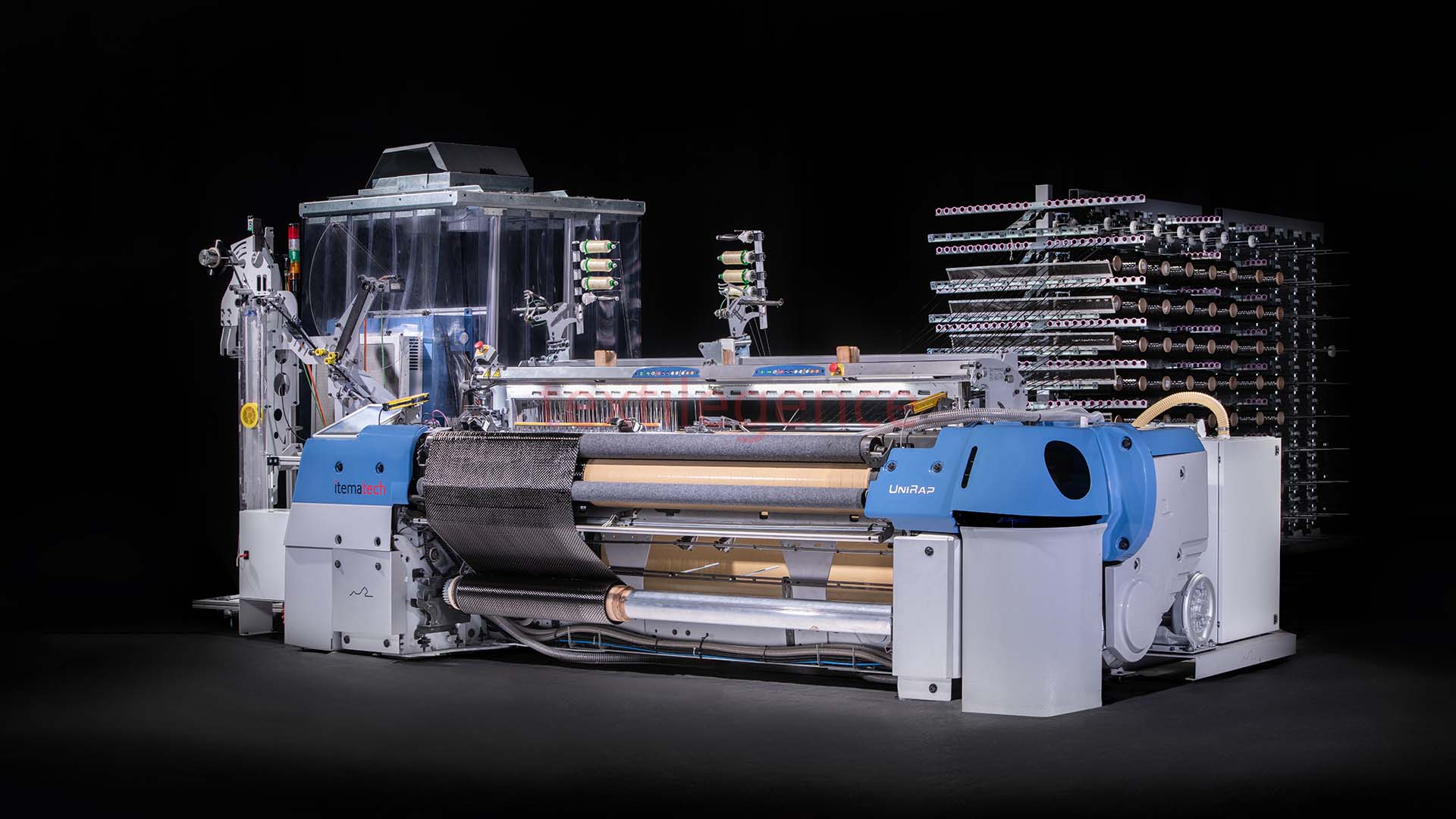

UniRap: The Itematech single positive rapier weaving machine

The absence of the weft exchange, thanks to the positive single rapier weft transfer, enables the Itematech UniRap to weave the widest range of high-tenacity yarns, from carbon tape and fibers, to fiberglass, aramid fibers, steel and lead-coated yarns, and many others. Designed as an open platform, the Itematech UniRap comes to the market in a double version specifically developed for technical textiles weaving: the UniRap | P Weft Insertion System enables the effective insertion of carbon tapes and tape-shaped yarns with no torsion up to 30mm, while the UniRap | G Weft Insertion System is ideal to weave the widest range of technical yarns. What makes the two versions even more interesting is the possibility to switch the two weft transfers easily and quickly, thus providing weavers with two weft insertion technologies in one.

Image Source: Itema

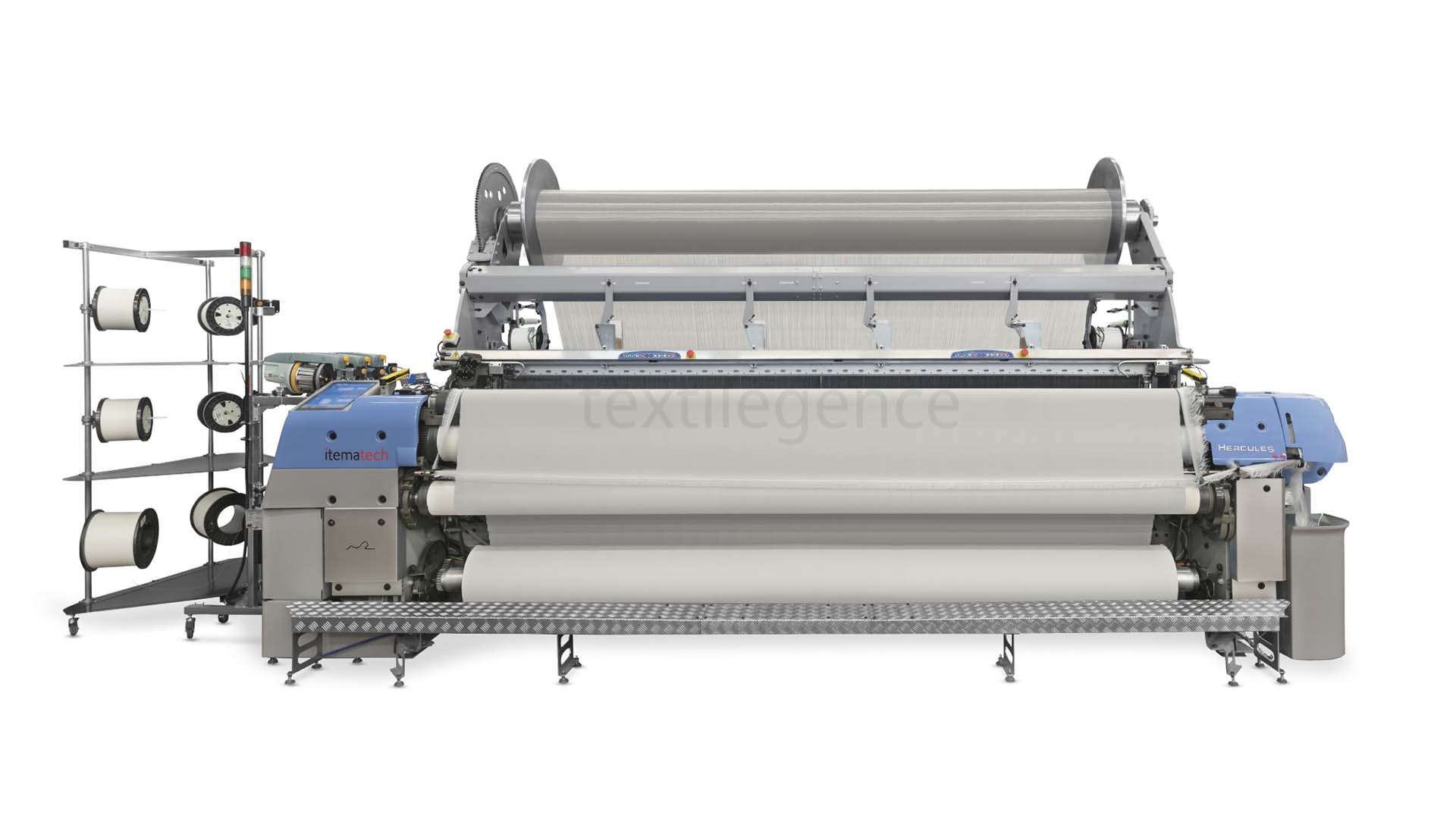

Hercules: The Itematech negative and positive rapier weaving machine

The Hercules reinforced machine structure coupled with its textile flexibility offers weavers the ideal weaving technology to produce the most demanding technical textiles, from extremely high density to the finest fabrics. Hercules provides outstanding textile flexibility thanks to its unique weft transfer system that enables the valuable possibility to switch easily and quickly from positive to negative rapiers, thus leading to superior textile efficiency when handling the widest range of weft yarns counts, from 20 up to 48,000 dtex, in single or multiple weft insertions configurations. Hercules is available in weaving widths up to 6200mm and features a modular structure, customizable according to weavers’ textile needs. In fact, the basic machine structure is reinforced and can be equipped with different devices capable of reaching a beating force of up to 5.5 tons (depending on the reed width). Hercules textile range includes but is not limited to agrotextiles, medium and heavy coating fabrics, medium and heavy conveyor belts, medium and heavy filter fabrics, fiberglass, geotextile, heavy canvas, geogrid, and plain carpet.

P7300HP V8: The Itematech projectile weaving machine

Technical fabrics are the specialty of P7300HP due to its reliable and versatile weft insertion system, based on the single insertion driven by the projectile which catches the weft and carries it directly with no exchanges, providing unmatched efficiency. The P7300HP continues to represent an unbeaten and unbeatable benchmark for those looking to weave the very widest fabrics (over 6 meters) and high-specialty materials, such as agrotextile, geotextile and primary carpet backing fabrics.

R9500EVO: The Itematech rapier weaving machine

The Itema R9500EVO is the latest version of the Itema best-seller R9500. The continuous roll-out of customized special versions tailored for technical applications, including coating, para-aramid, fiberglass, bolting cloth, fabrics for automotive, light filter fabrics, among others, as well as dedicated devices for each application make the R9500EVO the perfect machine for the manufacturing of the full range of technical textiles, including the ones with the finest monofilament yarns, multifilament yarns with high tenacity, and multiple pick insertion fabrics.

R9500EVO, equipable with the Itema iSAVER®tech, eliminates the waste selvedge on the fabric’s left-hand side, thus significantly reducing the wastage of raw materials and resources leading to cost reduction and contributing to sustainable weaving. iSAVER®tech is available to weave a wide range of technical yarns and it is even retrofittable as an upgrade kit on all R9500 series machine models.

A9500EVO: the Itematech airjet weaving machine

When it comes to weaving very high-density fabrics, the airjet A9500EVO is customizable with dedicated devices to ensure excellent results while answering to the most demanding weaving needs. In particular, the Itema Airjet A9500 iLENO for Secondary Carpet Backing has recently been launched on the market and rapidly gained popularity among technical weavers. This special airjet machine, indeed, has been designed by Itema to successfully and effectively weaving Secondary Carpet Backing fabrics with the goal to maximize weavers productivity and return on investment.