Jos Notermans

Choosing a digital textile printing solution nowadays means having to choose from a large number of printer manufacturers and ink suppliers. By nature, one of the first characteristics buyers pay attention to is the price of the machine or the ink. Sadly, buyers often only take these price tags into account when they select a machine or ink, and they forget to look at all the other costs that come with running the machine in a way that accommodates their production volumes. This so-called “Total Cost of Ownership” (TCO) is the real thing that matters and should determine a decision on what to buy.

In this blog, I explain why the Total Cost of Ownership is the most important factor when buying a digital textile printer and what hidden costs you should take into account when calculating the TCO and total digital textile printing cost.

Hidden digital textile printing cost

As pointed out, there are a lot of ‘hidden costs’ that determine the total digital textile printing cost. Are you thinking about buying a new printer? Make sure to base your decision on the Total Cost of Ownership of a machine so later on you don’t get ambushed by unexpected costs. Below you’ll find a list of additional costs that are often not clearly communicated during product demos or in meetings with sales.

Decision factor 1: printing speed

Hidden cost: What quality can you print at which speed?

I notice that when choosing a digital textile printer, people often determine their decision based on the top speed of the printer. Printer manufacturers show samples of the highest quality and then a bit later mention the top speed, but they ‘forget’ to point out that the highest speed cannot deliver that shown quality.

Every scanning printer has multiple speed levels. Each speed level is linked to a certain level of print quality. For a printer to deliver high-quality levels, it needs a four- or even eight-pass printing process, which is four to eight times slower than the top speed that is mentioned in brochures or sales pitches. Scanning machines can only produce their top speed at a two-pass or one-pass printing process. For this reason, printing at top speed always results in lower print quality levels, since there are no more passes to cover up mistakes. Especially in the fashion industry, where there is a large demand for detailed, high-quality prints, printing at top speed is hardly ever an option.

In order to make an accurate comparison between two digital printers, you should compare two samples that are comparable in terms of quality and then determine at which speed level both printers have produced that sample. That’s the only way to make a realistic comparison of digital textile printing costs. So the true question is: what level of quality does the printer produce at each speed level?

Decision factor 2: reliability of the machine

Hidden cost: How much do you pay for service and maintenance?

Reliability often plays a very important factor in choosing a digital printing vendor. After all, you want to buy a digital printer which you can count on. Nevertheless, it’s often inevitable that at some point you will have to make use of the service and maintenance team of the vendor. And more often than not, those additional digital textile printing costs are not taken into account when evaluating a digital printer. Especially when the vendor does not have service located in your region, the costs of having a service rep flown in can be quite high.

In order to create an accurate representation of the true total cost of ownership, make sure to ask yourself the following questions: what reputation does the machine have in terms of reliability in the market? How much warranty do you get on the printing machine? And finally: how much do service and maintenance costs?

Also bear in mind that every stop for service also means an interruption of your production and most probably some scrap meters of print before you discovered the printer needs maintenance. So even if service is local and cheap, you don’t want them on your doorstep on a regular basis.

Decision factor 3: required viscosity of the inks

Hidden cost: how much dye is really in one kg of ink?

All print heads require ink to have certain physical properties. An important example of these properties is the viscosity of the ink. In order to get the right level of viscosity certain chemicals must be added to the ink. If a higher level of viscosity is required, more chemicals are required.

The more chemicals are added to the ink, the less water it contains. Since color dye can only be added to the ink by dissolving it in water, inks with more chemicals (and thus less water) by definition will contain less color dye. In other words: if you want high-density ink, you need ink with a low level of viscosity. This means you have to select a printer that uses print heads that need a low viscosity ink. A nice side effect is that a low viscosity level also means the ink generally has a better runnability.

Looking at digital textile printing costs, choosing a type of ink with low viscosity levels can save you up to 20% of ink. For that reason, it is important when selecting a new digital ink to ask yourself the following questions: what viscosity do the printheads in my digital printer require?

Decision factor 4: ink usage

Hidden cost: How much ink does the printer uses when it’s not printing?

Another deciding factor for buying a digital printer that I want to discuss in this blog is ink usage. Printer manufacturers can calculate very accurately how much ink is needed to print a certain design, and most RIP software packages present those numbers for each design. However, the amount of ink that the printer uses when it’s not printing is not included in this number.

Before starting a print, after some standstill time, almost every printer needs to perform a quick flush to make sure all nozzles are open. This flush happens in the home position of the printheads and the ink used with this flush is going to waste. These are hidden ink costs. But also during printing, a scanning machine will regularly automatically clean its nozzles to ensure that all nozzles remain open. This is a quick cleaning cycle that takes place when the printing process is in full swing by moving the print heads for a short time to the “home” position. This cleaning cycle again causes the printer to use extra ink. A fact that is often not mentioned in product demonstrations.

Additionally, when a printer is idle for a while (for instance during the night), it needs regular flushing of the print heads. Otherwise, the heads will dry out. This is also a waste of ink. In order to prevent that from happening, a user can decide to switch off the printer. During this switch-off routine, the heads are again flushed (ink is wasted again) and then capped to prevent drying. But as soon as the printer is switched on again, the heads again are flushed automatically (or by the operator) to ensure all nozzles are open. Again, this is ink wastage.

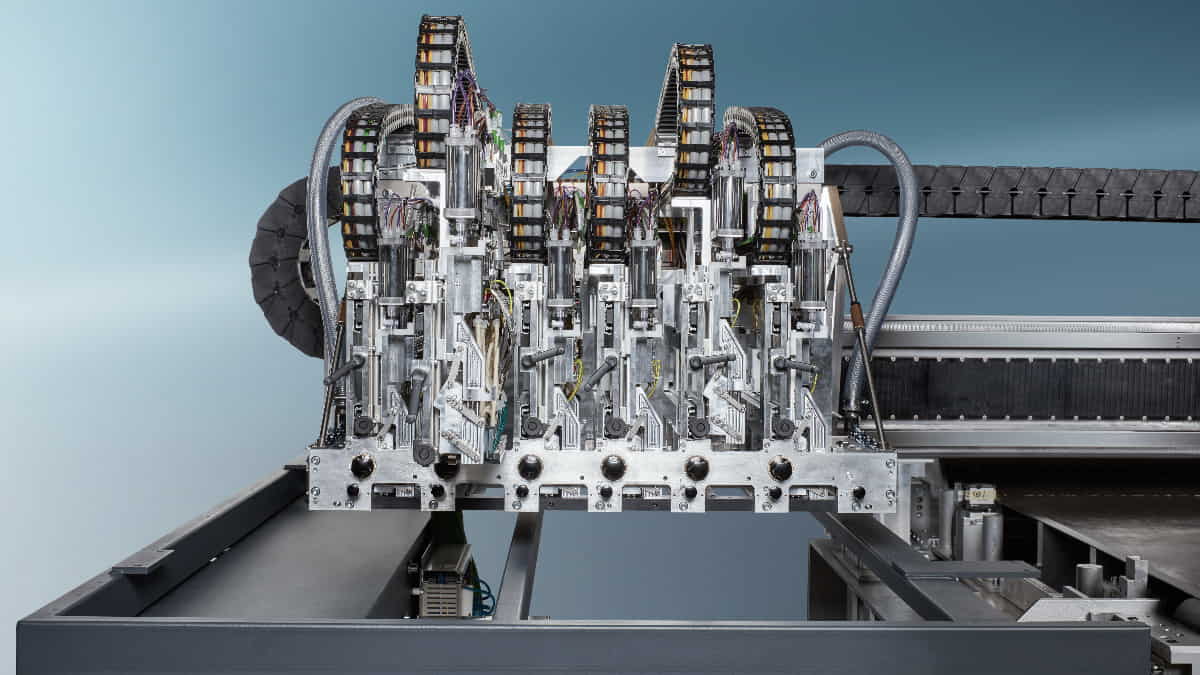

To avoid all this ink wastage, SPGPrints Archer+ Technology is equipped with continuous ink recirculation technology, all the way to the nozzle plate. This technology ensures that the ink is being circulated constantly, which prevents the ink from drying at the nozzles. This means that a printer that has been idle for a while does not need any flush cycle to start printing again, which saves a considerable amount of ink (and therefore digital textile printing costs) during a month or year. By always keeping the JAVELIN or PIKE printer switched on, you actually save ink.

For a digital printer that is not equipped with this continuous ink recirculation technology up to the nozzle plate, the real ink usage is often 20% to 30% higher. Many printer manufacturers don’t mention this ink spoilage, hiding behind arguments that ink consumption is mainly determined by the brand and type of ink you use.

Decision factor 5: runnability

Hidden cost: How often does the printer have to perform a cleaning cycle?

When choosing a new type of digital ink, the obvious thing that customers look at is the color density of the ink. However, they often do not realize exactly how big of an effect the runnability of the ink has on the overall printing process and the total digital textile printing cost.

In the previous chapter, I explained that cleaning cycles mean hidden ink costs as inks are wasted to clean and open up nozzles. A high runnability level means that the ink can easily flow through the print heads. When you choose a digital ink with a high level of runnability, your printer will require fewer cleaning cycles. Less cleaning cycles equals more printed meters per hour and less ink waste. This indicates that the type of ink you choose directly influences the productivity of your printing machine. For that reason, an important question to ask is: how many cleaning cycles have to be performed with this type of ink? And how does that influence the number of meters you can print per hour?

Digital textile printing cost: the three core investment reasons

Do you feel like a digital textile printer could be of value for your company? Then first you want to find out exactly how this transition could help you grow your business and get ahead of the competition.

Knowing which core advantages of digital fabric printing helped other textile printers to address new business units and assure a profitable future for their company will help you to make that decision. In an independent study of the textiles market, Gherzi, therefore, identified and analyzed the three main investment reasons for digital textile printing.

You can find the original version of the article here.