Carrington Textiles, the global workwear fabric manufacturer, will introduce new sustainable technology for textiles at Techtextil 2022, to be held in Frankfurt on June 21-24. Carrington Textiles, being the first textile manufacturer to use biodegradable technology to produce workwear fabrics, has announced their focus on the promotion of Orca and Hawksbill, as well as on their latest flame retardant addition, Flamestat 250, at its stand C56, in hall 11.1. In addition, the company has created a short online form where visitors can request a free pass to visit their stand, where a new commercial video will be promoted.

Carrington Textiles offers a sustainable alternative to its bestselling fabric Tomboy

Orca and Hawksbill, recently launched during the company’s ‘Weaving Sustainability into our Fabrics’ campaign, where they released their newest fabrics Constance 210, Balaton 255, Kielder 185, Delamere (210 & 245), and Rivington (205 & 220), stand out for their addition of the new CiCLO fibre. The CiCLO technology is a sustainable textiles ingredient in the form of an additive that is combined with polyester at the very beginning of the fibre making process. When CiCLO polyester ends up in the environment either through washing or end of life of the garment, it behaves like natural fibres, in turn reducing microplastic pollution and textile accumulation. Hawksbill’s composition includes 65% CiCLO polyester and 35% organic cotton, while Orca incorporates 26% recycled CiCLO polyester, 29% virgin CiCLO polyester and 35% Better Cotton. Hawksbill and Orca are the sustainable alternative to the company’s bestselling fabric, Tomboy.

Carrington Textiles Managing Director Neil Davey said that it is great to be able to attend exhibitions once again, and explained that they have invested a great deal of resources into R&D to bring these sustainable fabrics to market and have already had excellent feedback from customers and partners. Davey disclosed; “We are delighted to be showing them face to face to customers and all those interested at Techtextil.”

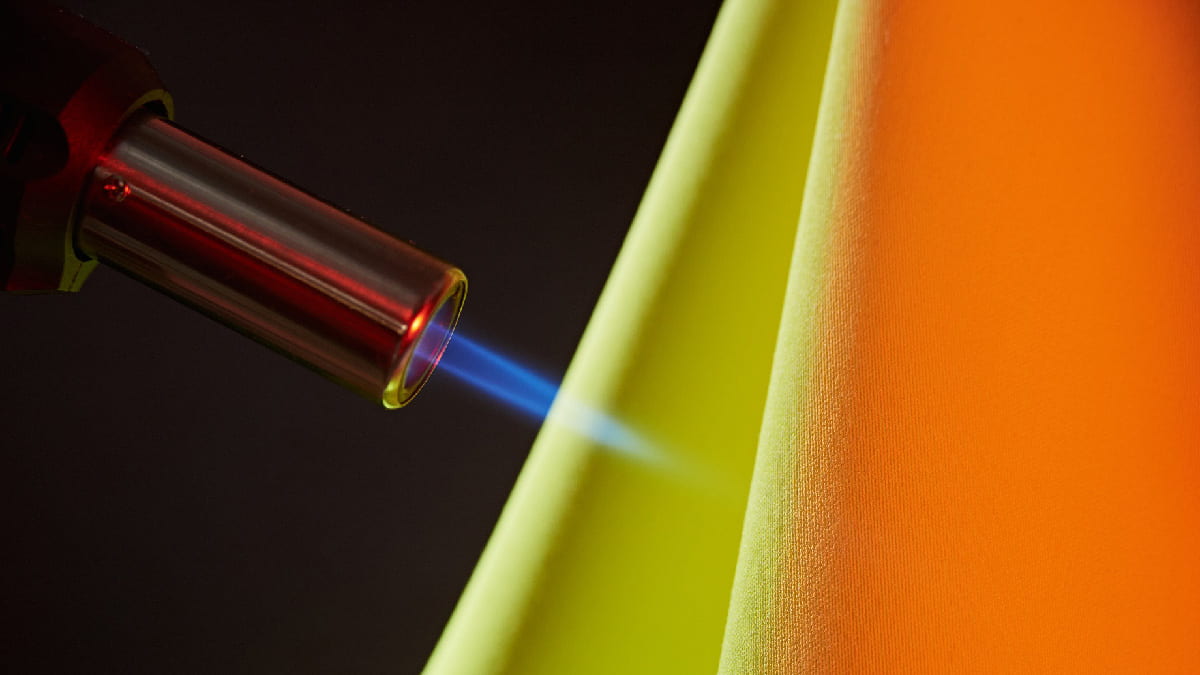

Flamestat 250 gsm, antistatic flame retardancy

Increasing the life of garments is a key focus of Carrington Textiles with the utilisation of fabrics that can withstand industrial washes and multiple uses contrary to the business model of fast fashion retailers. Flamestat 250 gsm, a new member of the Flamestat family, is guaranteed to last the lifetime of the garment due to its robust construction. With 75% cotton, 24% polyester and 1% antistatic, this fabric’s flame retardancy is to the standards EN ISO 11612, EN ISO 14116 index 3 and EN ISO 11611; while its antistatic properties are to the EN ISO 1149-3-5 standard.

In addition, Carrington Textiles’ new commercial video, which aims to reflect the manufacturer’s culture, global reach and sustainable message, will be screened to visitors during Techtextil 2022 and will be available on the Carrington Textiles’ social media channels from the beginning of June.