The new card C 81 from Rieter, one of the leading suppliers of short staple spinning systems, strengthens the market position of spinning mills with high production rates and excellent sliver quality. Representing a major innovation in carding technology, the C 81 offers new, intelligent functions in addition to maximum productivity and minimum energy consumption. Intelligent sensors in the machine optimise the carding gap, monitor the trash level in real time and monitor the raw material quality before and after carding process. Compared to the previous C 80 model, the new card offers higher quality and production.

10% higher productivity thanks to Carding Gap Control

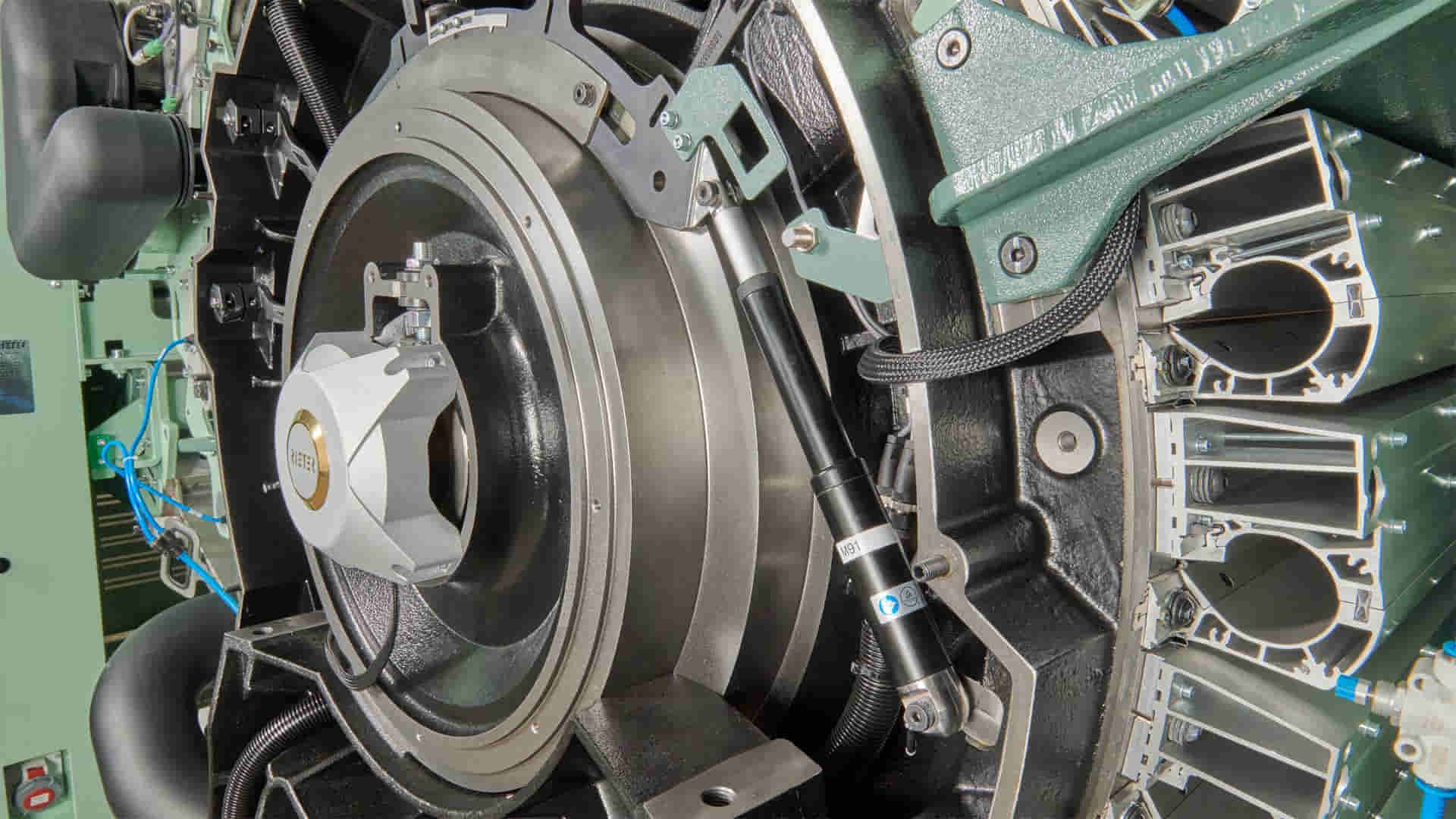

The more precisely the carding gap, which plays a crucial role in the carding quality, can be adjusted, the better the reduction of neps and the associated yarn quality. The card C 81’s outstanding innovation is that it can inspect the carding gap without contact. Carding Gap Control regulates the carding gap – the distance between the flat and the cylinder – accurately to a few hundredths of a millimeter.

On each of the 116 flats in use, the system detects the distance between the needle tips and the cylinder clothing and monitors this without contact. Intelligent software calculates the ideal carding gap by factoring in further important influencing variables, such as the machine temperature. The electronic, centrally adjustable flat setting constantly keeps this gap in the ideal range.

A comparison of the cases with and without the regulated carding gap shows an increase of up to 10% in production of the same quality, while this produces up to 10% better card sliver quality at the same production speed. This means fewer thin places, thick places, and neps. Carding Gap Control also has the advantages of higher machine availability and consistent quality, depending on the individually defined limit values. The Rieter card C 80 can be easily retrofitted with this new function.

New card C 81 increases raw material yield with artificial intelligence

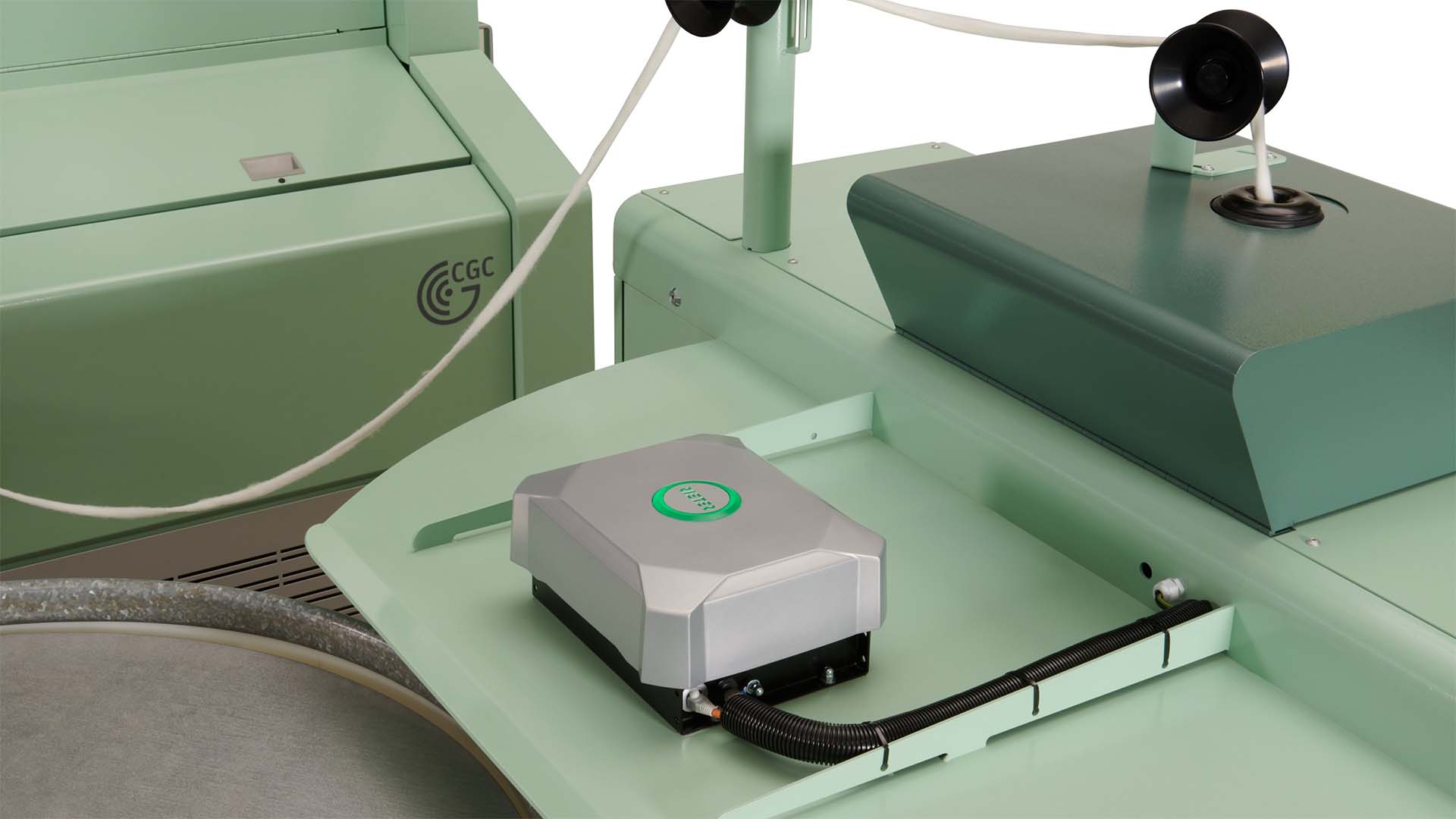

Another innovation of the C 81 is Trash Level Monitor, which continuously monitors the contaminant content of the fiber tufts in the card inlet and the card sliver produced. This is important for customers who process natural fibers, such as cotton. The heart of this function is optical image processing with a new neural network developed by Rieter. Sensors in the card infeed and at the sliver coiling section deliver the data for this.

Trash Level Monitor makes yarn quality predictable within a defined range. Artificial intelligence is used to determine whether the impurities in the card infeed and in the Trade Press Article Rieter Trade Press Article: Card C 81, June 2023 Page 2/2 produced card sliver lie within the defined limit value. This makes it possible to take measures to make sure that the raw material is used ideally, even at this early stage of the process. Trash Level Monitor is also available in a modular version and can be retrofitted into existing Rieter carding systems.