International technology group ANDRITZ will be presenting its innovative nonwovens production and textile solutions at IDEA 2022 in Miami, USA on March, 29-31. Visitors will be able to examine ANDRITZ wide product portfolio covering state-of-the-art nonwoven and textile production technologies such as air-through bonding, airlay, needlepunch, spunlace, spunbond, wetlaid/ WetlaceTM, converting, textile finishing, recycling and natural fibre processing at the company‘s booth 4104. In addition, customers who cannot travel to Miami due to travel restrictions will have the opportunity to discover state-of-the-art technologies, obtain the latest marketing material and press information, and meet the ANDRITZ team at the firm’s virtual booth called ‘ANDRITZ Teleport’ during the show.

ANDRITZ will showcase technologies for biodegradable wipes at IDEA 2022

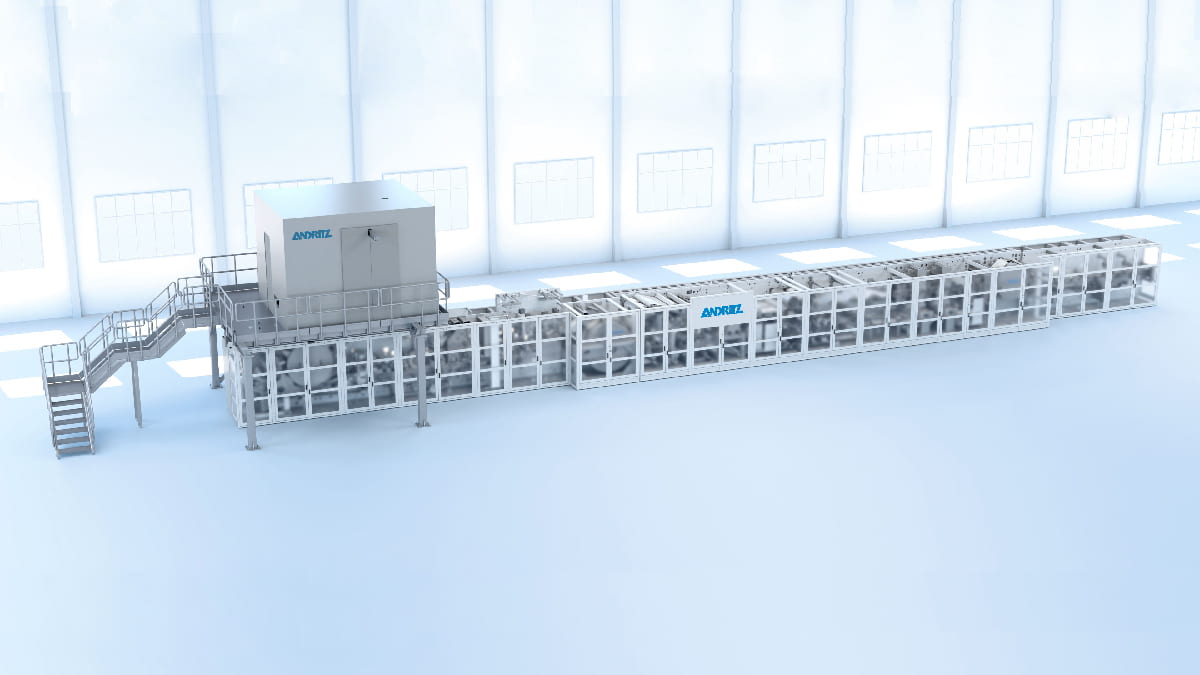

ANDRITZ offers various nonwoven processes to produce best and cost-effective wipes, like spunlace, Wetlace and Wetlace CP and also accompanies nonwoven producers in the move to sustainability with the aim of reducing or eliminating plastic components while maintaining the high quality of the desired product properties. This applies to all types of sustainable wipes, such as flushable, biodegradable, bio-sourced, carded-pulp or standard carded wipes. Hydroentanglement has the advantage of being able to bond any kind of fibres without the use of chemical binders or thermal fusion. It is, therefore, presented as the most suitable bonding process for natural fibres, such as pulp, cotton, hemp, linen, flax, bamboo, and more. The latest development in this field is the ANDRITZ neXline wetlace CP line, which integrates the card-pulp (CP) process. This is a fully engineered production line combining the benefits of drylaid and wetlaid technologies to produce a new generation of biodegradable wipes.

Solutions for hygiene applications

ANDRITZ will highlight the technology development in the spunlaid sector with the patented nonwovens process called Spunjet Soft. This is the in-line hydroentanglement of continuous filaments, creating a new generation of premium spunlaid nonwovens with unrivalled bulkiness and softness compared to standard spunbond fabrics. In addition to samples of absorbent hygiene products integrating spunjet soft materials, the company will also exhibit its adult pants converting line, offering top-class components and an innovative technology process at its booth.

Innovations for durable applications

Another point that the company will focus on at the show will be durable nonwovens, especially for the automotive industry. While the use of nonwovens in the automotive has increased substantially in recent years, the automotive industry is moving its focus to green technologies that have a direct impact on the characteristics of nonwoven parts in vehicles. Producers are able to provide the most suitable fabrics for this industry’s requirements with ANDRITZ airlay and needlepunch processes.

The ANDRITZ airlay technology can process all types of fibres and solid particles. It is offered as a complete line with needlelooms, thermobonding or other bonding methods for numerous applications in the automotive and also the furniture, bedding, insulation, and filtration industries. In addition, ANDRITZ is presenting the brand new ProWinTM technology for profile weight correction in the needlepunch segment, which is used to optimize processes, provide a faster return on investment, and save raw materials. This unit combines the well-known systems ProWid and ProDyn, enabling even better performance, and the same machine can run faster with less mechanical stress. ANDRITZ also has technologies for textile recycling and processing of recycled fibres.

Spot-on and digital service to keep machines running

ANDRITZ offers a full-service portfolio and thus can ensure improved uptime, productivity, and product quality – for years to come, including on-site support, specific training, line audits and troubleshooting, upgrades and modernizations, spare parts, and roll repair centres. ANDRITZ is well supported in sales and service by its local branches in the USA – ANDRITZ Küsters in Spartanburg, SC, and ANDRITZ SHW in Torrington, CT.

Moreover, customers can bring their production to a new level with ANDRITZ digital technologies combined under the Metris technology brand. Metris UX digitalization platform, which provides full support for industrial plants throughout their entire life cycle, combines a complete set of functionalities for professional production management, simulation and optimization using the latest artificial intelligence methods, plus cyber security, and condition monitoring with smart sensors in an integrated approach. The company will offer a live demonstration at its booth at IDEA 2022.

ANDRITZ will also meet visitors with its innovative solutions for nonwoven production and textile production at its booth 21F30 at INLEGMASH 2022, which will be held in Moscow, Russia on March, 14-17.