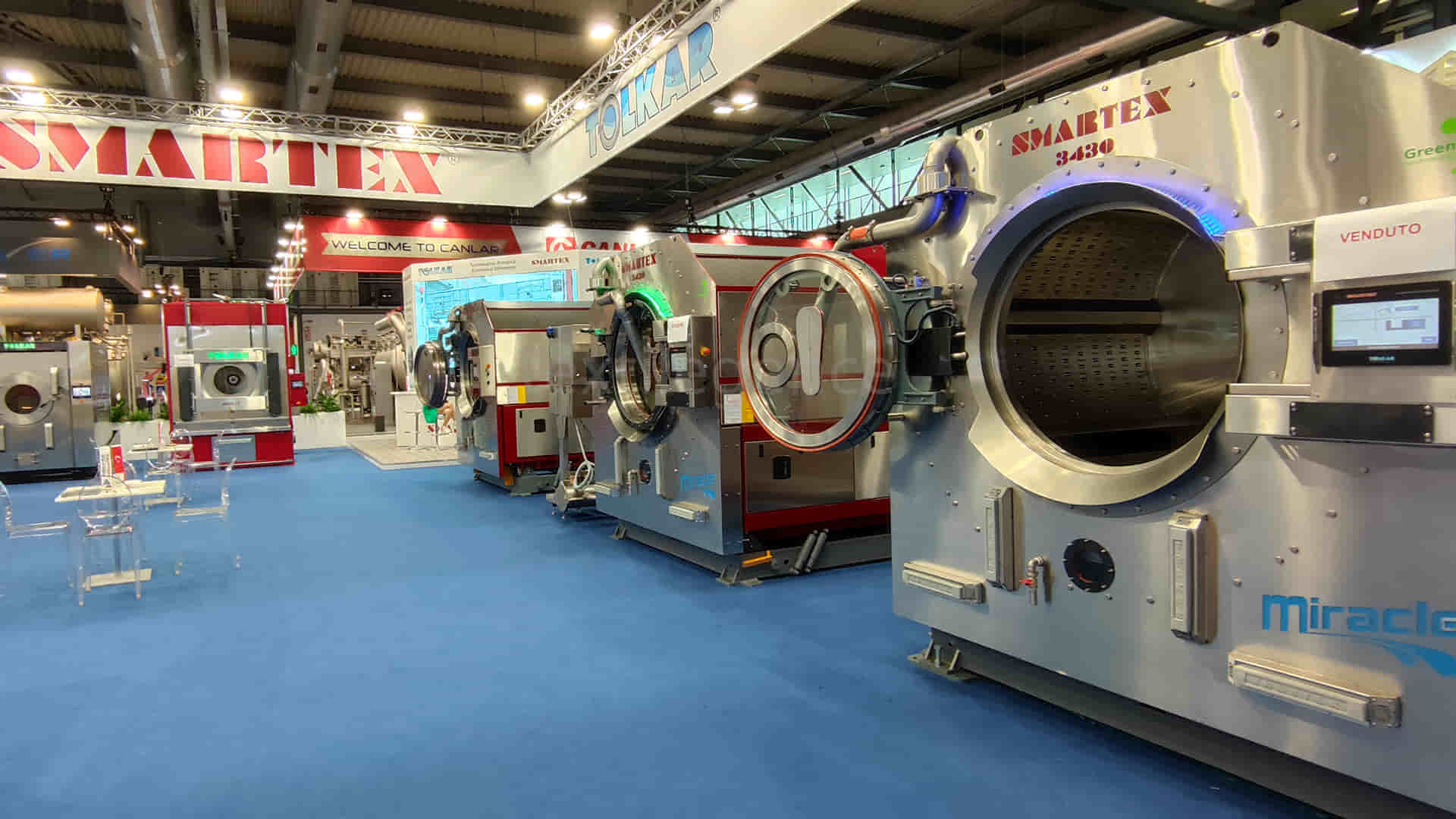

TOLKAR shared its technologies for quality and sustainable washing processes with the global textile industry, demonstrating Smartex machines at ITMA 2023, Visitors from all around the world had the opportunity to examine the washing and extraction process carried out in a single machine and the details of the technologies that enable a more sustainable production at the booth where machines of different capacities were in operation.

Giving an interview to Textilegence, TOLKAR Board Member Ata Karace stated that they are pleased to come together with the industry after a four-year break. Saying that they observed a decrease in the number of visitors to their booths compared to the ITMA 2019 held in Barcelona, Karace indicated that they attracted great interest from Türkiye, especially İstanbul, İzmir and Denizli, as well as from Italy due to the location of the exhibition. Karace also said that they met with visitors from many other countries, including India, Argentina, Peru, Mexico and Brazil.

With Smartex, washing and extraction in one machine

Underlining that they make a difference in the sector with Smartex machines along with performing the only extraction test in washing machines, Ata Karace said: “Actually, the most important detail in washing machines is the extraction process. At this stage, after the product has been washed, the machine should extract at the highest speed achievable to remove maximum moisture and then dry the product with as low moisture as possible. Generally, our competitors produce and sell the extractor separately. Instead, we promise users to finish all the processes in a single machine. The most important point in washing is that all goods come out with an equal amount of moisture while external extractors are unable to achieve this. Naturally, this has a direct negative impact on production quality. In addition, performing two processes in a single machine saves time and reduces the workload.”

“400 G extraction force with zero vibration”

Karace pointed out that each of the Smartex washing machines is also a high-speed extractor, saying that they operate completely vibration-free at 400 G extraction power. Karace stated that there are no competitors that can reach this power in the same capacities and continued his words as follows: “The vibration-free extraction process is unique in the world. Generally, washing machines have shock absorbers and spring systems. In our machines, however, we have a patented dynamic balancing system. There are balancing tanks in front and behind the machine. If there is an imbalance at any point, the system automatically detects the vibration there and injects the required amount of water in the opposite direction. Until the vibration stops, the system increases the amount of water level by level until the vibration stops, thus restoring the balance.” He also underlined that vibrations are the most damaging factor for the machines and added that by eliminating the vibration completely, they also extend the service life of the machine.

“Smart machines need expert users”

Mentioning that they produce the world’s highest level of washing technology, Ata Karace emphasized the importance of the fact that advanced technology and smart machines should be used by people trained in this field. Karace noted that the operators’ lack of sufficient knowledge on the high-level machine they use results in user-induced machine failures and emphasized that for this purpose, they offer operator training to their customers upon request. He also remarked that they offer their customers an infrastructure service that enables detailed analysis of data from smart machines.

Smartex machines saved enough water to fill 25 thousand Olympic-size pools in 15 years

Ata Karace, reminding that in 2008 they acquired Smartex company with all its rights including technology, patents and employees, said that with this acquisition, TOLKAR took an important step in terms of sustainable production. Highlighting that Smartex machines reduce water use by half and in parallel, the use of chemicals decreases at the same rate, Karace disclosed: “Smartex machines, which are 1.5-2 times more costly compared to traditional machines, amortize this investment difference in about a year with consumption advantages. At the end of one year, the user starts to achieve cost savings in water, electricity and chemical use and also significantly reduces their environmental impact.”

Karace stated that in 2008, they increased the number of machines produced once a month to 12-15 machines with varying capacities, and explained the total amount of savings provided by Smartex machines, which have been produced since 2008 and are currently in operation, with the following figures: “First of all, we made a breakdown of the number and capacity of the machines we produced on a yearly basis, and then we multiplied these figures by the average minimum working time of the enterprises. As a result, we realized that Smartex machines have saved enough water to fill 25 thousand Olympic-size pools in 15 years. This is a very significant figure.”

“We draw strength from our customers in our R&D studies”

Ata Karace stated that one of the most important topics within the scope of sustainability-oriented research is ozone technology as it eliminates the use of water and chemicals and evaluated their work in this field. Emphasizing that the continuous feedback, demands and expectations of their partners are an important driving force for them to improve themselves, Karace said: “Experts in our R&D centre carry out studies on new technologies, especially ozone. We test these studies on the relevant textile products by requesting samples and pieces from our customers. We prepare end products with different appearances for our customers who produce both knitted and woven textile products with ozone technology without using water and chemicals.”

Karace added that Smartex will always remain at the forefront for them: “It is our flagship. We want all producers to use Smartex and reduce their use of all natural resources, including water, by half. We want to protect our natural resources for a greener future.”