A.I.T., which has made a name for itself in digital textile printing with its artificial intelligence-supported solutions, demonstrated their solutions for pattern making and printing at their booth at ITM 2024. Stating that the patterns and prints exhibited were designed and printed on their own machines, A.I.T. Digital Marketing Expert Melih Yıldız disclosed: “We used our own solutions and the materials produced with them in every corner of our booth at this exhibition. In this way, most of the visitors from different countries visiting during the exhibition had the opportunity to explore the A.I.T. universe”.

Pattern applications can be seen in seconds with the 3D wrapping system

Melih Yıldız indicated that one of the main solutions that stood out at their booth was the artificial intelligence-supported 3D wrapping system, which they introduced for the first time exclusively at this exhibition, and that it was met with great interest. Stating that this system provides the opportunity to see the patterns digitally on the desired product in a realistic way, Yıldız said: “Using the 3D wrapping system, users can select all the details from the texture of the fabric to the position of the pattern. These can be applied in seconds onto existing templates such as t-shirts or dresses. With the improvements to be made in the future, it will turn into a more comprehensive platform where users can create their own templates.”

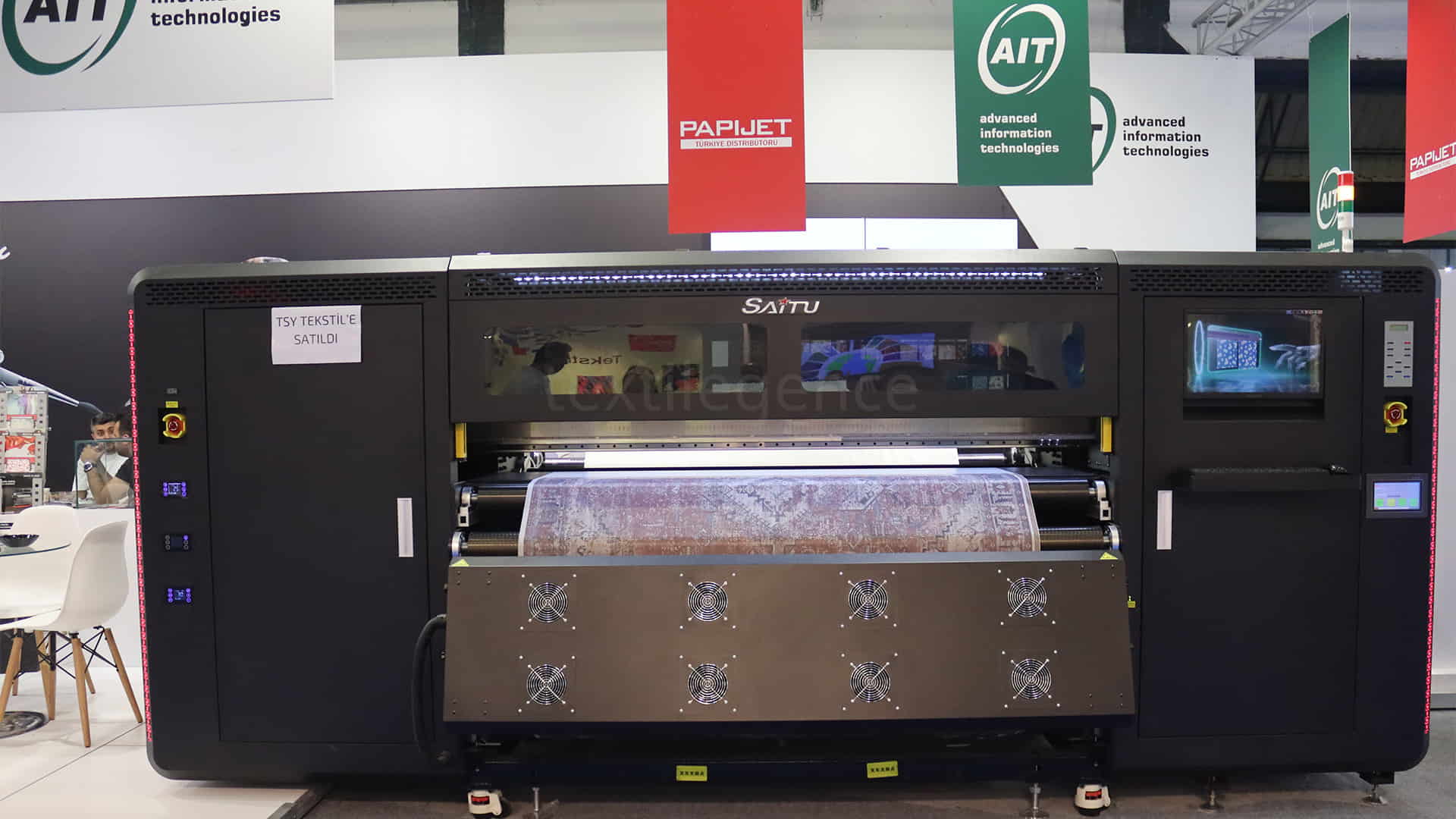

Noting that the SAITU JC 2036 30-heads textile digital printer they launched attracted a lot of attention, Yıldız relayed that they sold a machine on the first day. He commented: “Our new 30-head machine can reach speeds of 950 square meters per hour. The industry now needs faster and higher quality production with a single machine. In this sense, our machine responds to the demands of the industry. Another important point is that after purchasing our machine, A.I.T. will be your only contact on all matters. We provide services under one roof, from transfer printing papers, digital printing inks, printers and spare parts to technical service and software support”.

Unlimited pattern production on unlimited media

Underlining that they produce all solutions, from software to servers, under the roof of A.I.T. with their team of approximately ten people, Umut Savaşım Çeliker, R&D Team Leader at A.I.T. said: “We used the digital screens on our booth at ITM 2024 directly in a closed network, without even needing the internet, by bringing our own server here. We make our system serviceable to our customers in our own data centres. At the same time, we also ensured that this software works on the web, which is its biggest advantage. In this way, regardless of the medium, whether it is Windows, Mac, IOS or Android, you can start making your patterns on our official website, even from your television connected to the internet at home.” Adding that they are also working on an application, he shared the information that by accessing phone hardware, they will be able to promise some artificial intelligence tools to their customers in the future, perhaps without using the internet at all.

“With artificial intelligence, we reduced the pattern working time, which used to take up to 1 week, to 10 seconds”

Çeliker said, “Artificial intelligence is not something we do, we took artificial intelligence and developed it according to the needs of a niche sector, textile” and shared the following details about the process: “For this, first of all, we prepared a very large data set and introduced each of the patterns one by one to artificial intelligence. We indicated the features of the pattern such as its function, type and colours. Afterwards, we made it able to respond to these details more clearly. We also launched it with a beautiful and simple interface. In this way, designers can add the patterns they want to different objects and arrange them as they wish, and the work is presented to them with 4 different variations in an average time of only 10 seconds. Then, in order to have a commercial value, we made these patterns, which were produced as panels, available for meter printing within the framework of the designer’s wishes. Thus, we reduced the pattern working time, which used to take approximately 1 week or 10 days, to 10 seconds”.

In addition, he stated that today, clothing companies are demanding detailed information from their manufacturers, from the paper they print by the sublimation printers to the temperature/flow rate of the transfer machine they transfer to the fabric, and said that this is why they started to offer a certificate. “The certificates that A.I.T. provides to its customers include information such as which company, on which date and time, and by which designer the pattern was produced, along with a preview of the image of the pattern. This strengthens their hand in the market on the export side and provides them with a safe space,” he noted.

“Artificial intelligence is not the enemy of designers, but their friend”

Referring to the fact that designers in the industry sometimes perceive artificial intelligence as a threat to their own jobs, Çeliker made the following statement: “What we are actually promising here is not to completely take away the labour force of the designers, on the contrary, to assist them much faster and increase their creativity. and to ensure that they can present it without limits. Just as it is not possible for a person who does not know how to use a computer to do any work today, the same will be true for artificial intelligence tomorrow. We foresee this. Artificial intelligence is the friend of designers, not their enemy. Therefore, instead of worrying about this issue, designers should immediately improve themselves by looking for the power of artificial intelligence and ways to use it in their work”.