German textile machinery manufacturer Trützschler, standing out in the market for more than 130 years with its expertise in fiber and spinning preparation, left behind a full 2024 by investing in innovation, strengthening local support, and embracing digital transformation. The company has rolled up its sleeves to create new-generation machines in the new year. In the interview with Dr. Bettina Temath, Head of Global Marketing at the Trützschler Group, at the company’s factory in November, we talked about the Trützschler’s activities in 2024 and their strategies and innovations for 2025.

Trützschler’s Uşak Facility in Türkiye serves over 800 card installations in the region

Bettina Temath underlined the significance of Türkiye as a key market, mentioning their strategic decision to establish the facility in Uşak in 2024. “This centre is primarily a service provider for Türkiye, particularly the Aegean region, equipped with a warehouse, repair shop, and laboratory. This facility ensures faster and more competent service for the region’s customers who operate over 800 cards,” she said and noted that it has improved local service delivery, with Turkish customers expressing satisfaction. She added that this facility ensures fast and efficient service, enhancing customer confidence in the brand.

Mentioning the Turkish market outlook; “The economic situation is uncertain, but the Turkish market has always been resilient. I praised the proactive mindset of Turkish customers, who consistently find ways to adapt to challenges,” she said. She also addressed concerns about inflation, high loan costs, and investment hurdles in Türkiye, noting the importance of releasing exchange rates to support exports and expressing hope for a brighter economic landscape in the latter half of 2025. “We’re focusing on providing the best support to our customers, making their lives easier in terms of cost, productivity, and quality,” she added.

Trützschler customers adapt to digital transformation with My Mill

Dr. Bettina Temath mentioned their solutions in digitalisation, saying that the My Mill system, a mill monitoring solution, represents a leap in digital innovation. She explained that the ‘Digital Startup’ program assists customers in connecting all machines to the My Mill system and this enables centralized monitoring and performance optimization. “Once the system is established, customers are able to request personnel to demonstrate advanced reporting and statistics. While My Mill is being rolled out globally, it has seen significant adoption in Türkiye and India,” she continued. Temath added that data security is a top priority, allowing customers to share only the information they choose.

“TC 30i is a game-changer”

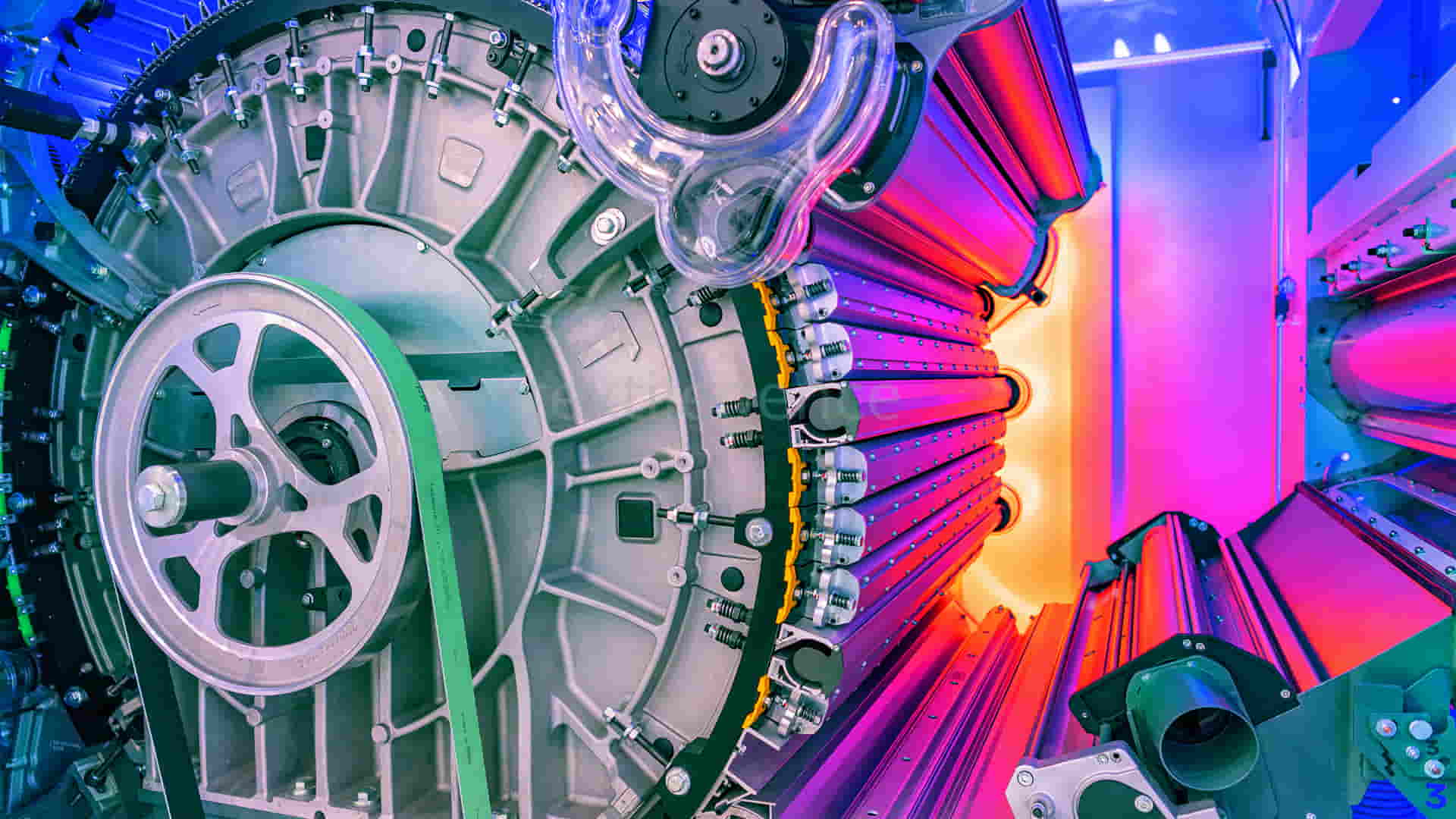

Dr. Bettina Temath said that in order to enhance customer service, they introduced efficient machinery such as the TC 30i, IDF 3, and TCO 21XL in 2023, and emphasised that these machines are pivotal in improving productivity and quality for their customers.

She relayed that the TC 30i emerged as a game-changer in the textile machinery market and highlighted its enhanced features, including an increased cylinder diameter, 38 active flats, and the T-GO Gap Optimizer, which ensures consistent carding gaps for better quality. “A sophisticated waste suction system increases the amount of reusable high-quality waste that customers can use or sell. These innovations have driven the machine’s success, with rising sales globally, particularly in Türkiye,” she relayed.

“We are developing the next generation of machinery”

Bettina Temath said that Trützschler remains committed to innovation, while global markets have slowed: “We are continuing our R&D studies as planned. There are no cuts because delivering state-of-the-art innovation with added value is our priority,” she remarked.

Saying that they are developing the next generation of machinery, including advanced cards and draw frames, Temath emphasised that the quiet market has been an opportunity to invest heavily in R&D. “We are not just working on future machinery but also optimising current installations to deliver better results for our customers,” she stated.

In addition, Temath, sharing her opinions on the industry’s crowded trade fair schedule, defined this as an aftereffect of the COVID-19 pandemic and expressed hope for a return to a more sustainable rhythm. “For our industry, annual trade fairs are not in every case beneficial. Effort and outcome are not always in a good balance for both exhibitors and visitors” she commented.

“Our focus on spinning and nonwovens”

Bettina Temath explained the discontinuation of their business in man-made fibres as a strategic decision, saying; “We have signed an agreement with the company Oerlikon. The agreement ensures the service and supply of spare parts for the machines and systems installed in the market for the production of carpet yarns (BCF) and industrial yarns (IDY). Thus, we are focusing on spinning and nonwovens, which aligns with our core strengths and future vision.”

She explained that training and after-sales support remain central to Trützschler’s customer engagement strategy; “Our technicians train customer personnel during the installation process. Additionally, our technical centre offers opportunities for trials and advanced training. This commitment to service ensures customers maximize the potential of their investments,” she said. She concluded by saying they are always ready to support their customers through challenges and deliver the best solutions for their success.