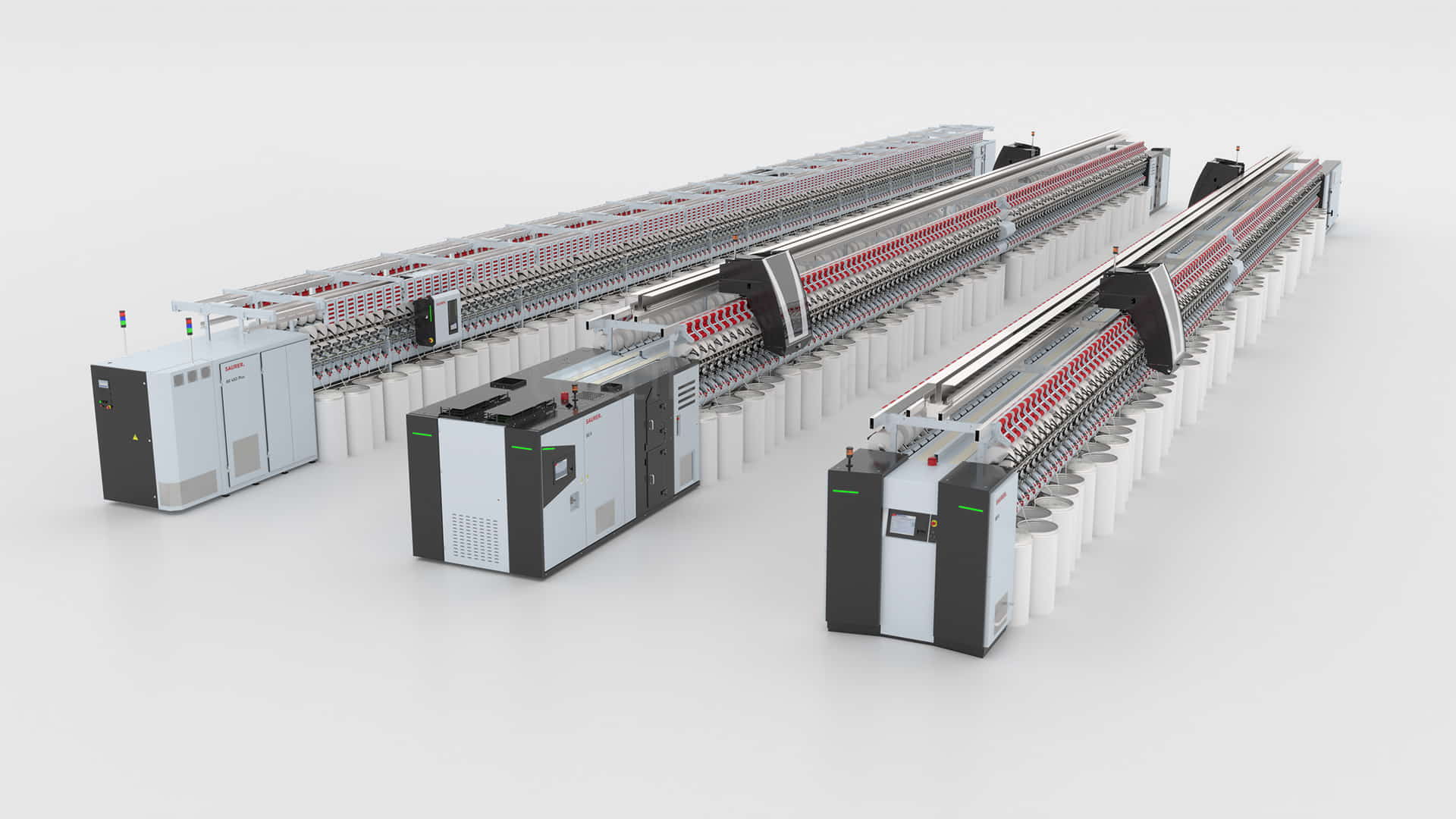

Saurer will present its spinning and twisting machines’ power to produce yarns that define the fabric’s characteristics to meet the needs of the fashion and interior industry at ITM 2024. At booth 709 A in hall 7, visitors will discover energy-saving solutions for pre-spinning, spinning, and twisting the machines’ flexibility and versatility enabling competitiveness in the changing textile world. Saurer, the sole supplier with all five spinning applications, offers air, rotor, ring, compact, and worsted ring spinning and its twisting machines can twist almost any yarn, from fine wool to carpet and technical to glass fibre yarns.

Saurer will introduce the new Autoairo 11 to produce commodity yarns at competitive costs, running at 500 m/min at the booth. A big focus will be on recycling, visitors will be able to see the energy-saving BD 8 and learn more about the Autocoro 11 with recycling Xtreme Edition. Besides, the new Zinser 51 ring spinning machine generation will be presented for the first time in Türkiye. The visitors will have the opportunity to see Zinser 51 in operation in addition to finding out how Saurer’s Autocard use digitalised settings to improve sliver quality and be inspired by the capabilities of the CarpetCabler/CarpetTwister 1.12 exhibited at the booth.

Fashion and interior design start with yarn

Many fashion trends are inspired by the yarns available on the market. Saurer plays a key role in shaping fashion and interior trends with its yarn innovations. Besides energy saving, Saurer’s engineers also focus on technology – constantly inventing new ways to spin yarns and enhance yarn quality.

Here are some of the market trends and what Saurer has to offer:

- Yarns for fabrics with high washing stability, low pilling, and durability: Belairo yarns from the new Autoairo 11 air spinning machine are ideal for polo shirts, towel piles, or fine knit fabrics.

- Yarns from recycled raw material and waste: The fully automatic Autocoro 11 rotor spinning machine in the Recycling Xtreme edition and the Synchropiecing 60 help process extremely short fibres with high productivity. The semi-automatic BD 8 rotor spinning machine ensures cost-effective production of recycled yarns, especially for waste spinning.

- OE yarns with a free blending ratio of two slivers: This new yarn innovation appeals to customers seeking to create unique colour or material blends.

- Fancy yarns for pattern effects in fabric: The Fancynation software enables fabric simulation and digital transfer of yarn effects to the machine. Fancynation is available for Saurer’s complete ring- and rotor-spinning portfolio.

- Elastic core or duo-core yarns: These core yarns spun on Saurer machines ensure the perfect fit for skin-tight clothes, jeans, or sofa covers.

- High-quality compact yarns with lower hairiness and higher strength: Spin compact yarns for the finest shirting fabrics with the self-cleaning compact device Impact FX pro.

- Sophisticated high-quality carpet yarns: Twisted on CarpetCablers and CarpetTwisters for decades, these yarns are used in high-end carpets and other textiles. The versatile machines master even the most unusual market requirements reliably and confidently.

Autoairo 11 air-spinning machine

Saurer’s Autoairo 11 air-spinning machine offers the flexibility to process different fibres, even simultaneously, thanks to Multilot: cotton, polyester, viscose as well as new chemically regenerated fibres. The Autoairo sets new benchmarks for producing high-quality air spun yarns named Belairo. These yarns have high pilling resistance and are very durable. The spinning process itself also sets new standards. Compared to combed ring spun yarn, the production of Belairo yarns uses less energy, less manpower, fewer machines, and less production space, which means lower building and air conditioning costs.

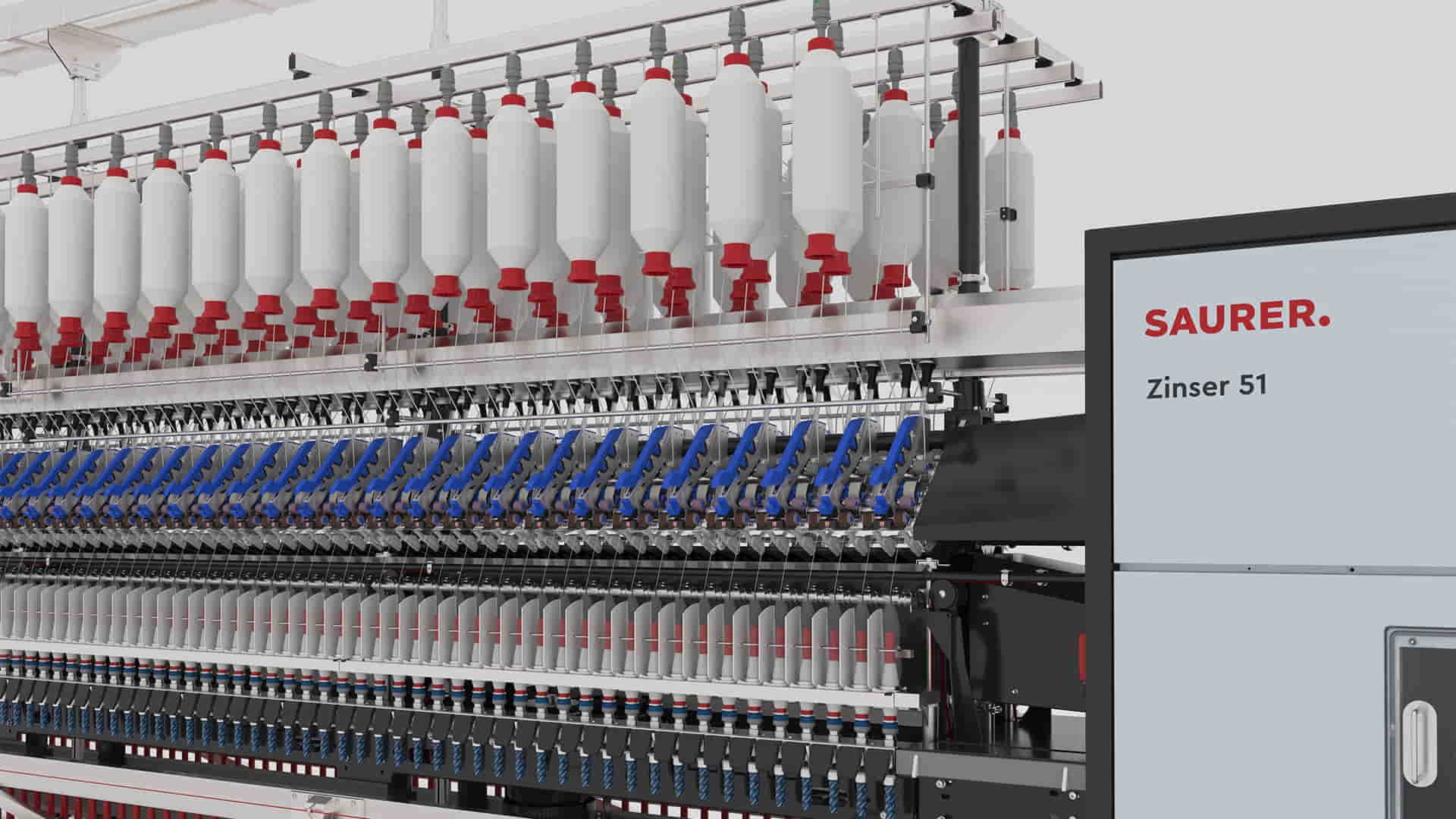

Zinser 51 – Saurer’s new ring-spinning machine generation

Saurer presents the Zinser 51 ring spinning machine series for the first time in Türkiye. The Zinser 51 series sets new standards for economical spinning. The new suction system, combined with proven energy-saving features, reduces energy consumption. The new NSD-i drafting system monitors all drives to ensure consistent yarn quality values over the entire machine length and speeds up lot changes. The robust intermediate drive Flexidriver NFD ensures consistent yarn quality on extra-long machines. High-end components such as the Texparts Eshape spindle and Spinnfinity, ideal for high-speed spinning, enable top speeds of up to 30,000 rpm. To produce high-quality compact yarns, the new Zinser 51 can be equipped with reliable compact units Impact FX and Impact FX pro.

Saurer machines, making a difference in energy saving for decades, will be on the ITM scene with new advancements. The latest Texparts product innovations and automation solutions will also be included at the company’s booth.

Today, 280,000 Autocoro spinning units are in operation in Türkiye

A look back at Saurer’s history shows how important the Turkish market has always been. Dr. Tai Mac, Director Product Management Open-End, reflects: “In 2011, the very first Autocoro with individual drives was shown at a customer day in Kahramanmaraş, Türkiye. Since then, Autocoro has been on the road to success. Today, more than 280,000 Autocoro spinning units are producing rotor spun yarn in Türkiye. Due to the many years of experience with this technology, it is no wonder that the very first Autocoro 11 installation with 768 spinning positions per machine at Biska Tekstil in Türkiye has performed well from the very first moment.”

Richard Klein, Regional Sales Director Twisting Solutions, notes: “A recent trend in Turkish carpet production is to use POY, DTY and FDY yarns instead of just BCF yarns. Our CarpetCabler/CarpetTwister 1.12 offers maximum flexibility and is able to process all these yarn types with increased productivity. This is made possible by the fully electronic headstock with inverter drives for the spindle, take-up and traverse motion. In addition, the 1.12 series offers an energy-saving spindle range and central computer-controlled balloon adjustment.”