ITM 2024 visitors will witness the latest innovations from the Trützschler Group, featuring machines and technologies in spinning, card clothing, and nonwovens, on June 4-8 in İstanbul. At the company’s booth 714A in Hall 7, all customer-oriented solutions that provide more productive and sustainable processes can be discovered throughout the exhibition.

Latest digital technologies for spinning mills

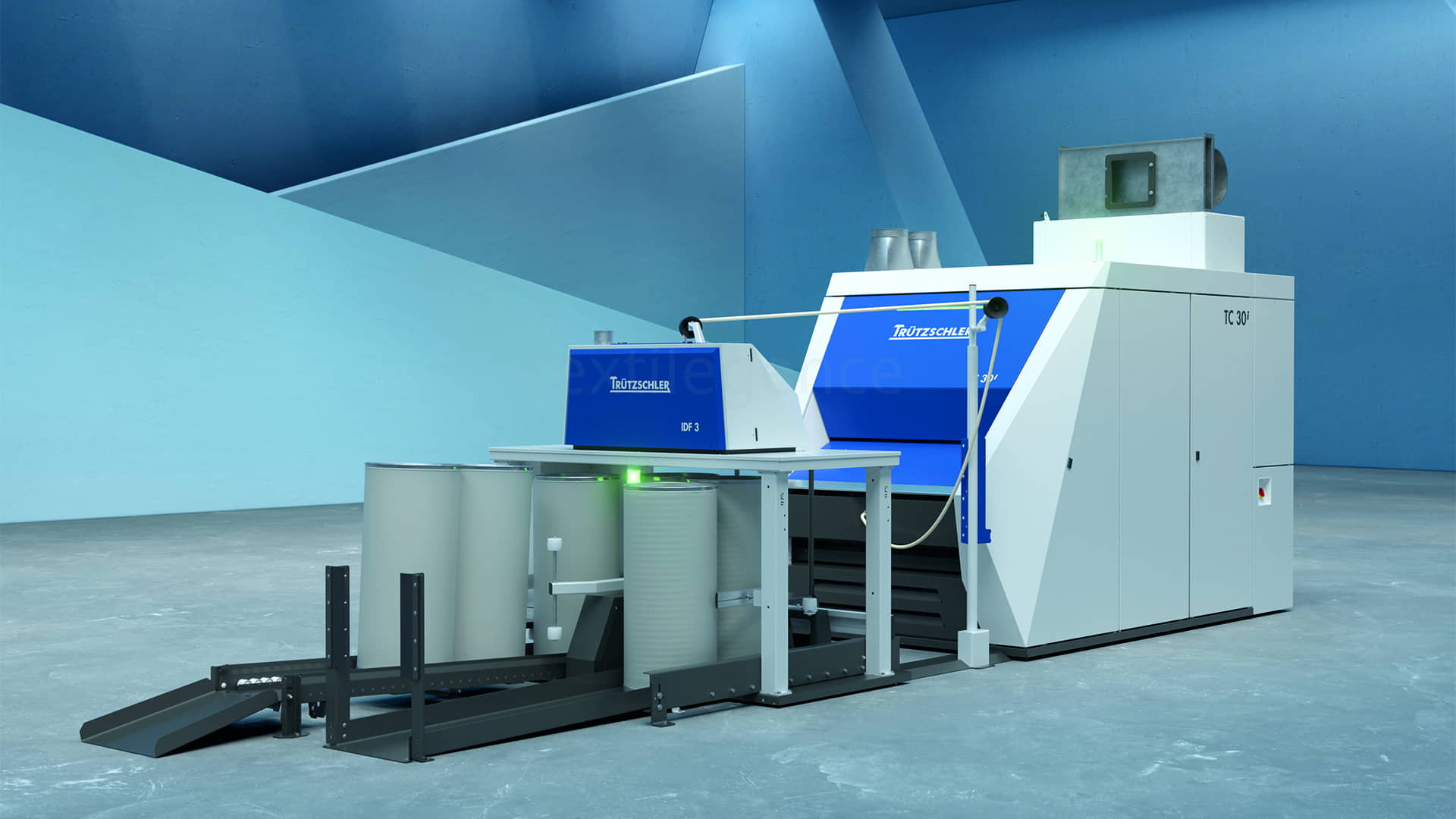

Trützschler Spinning will meet the latest in carding, draw frame and combing with the industry. All innovations address fundamental customer needs in fiber processing: high efficiency, more sustainable raw material utilization and intelligent automation. Additionally, the Trützschler team will present the latest digital technologies designed for spinning mills. Specifically, the booth will feature a full-size display of the TC 30i card and the integrated draw frame IDF 3. Visitors will further have the opportunity to discover the TCO 21XL, the world’s first 12-head comber.

Visitors will also have the chance to discover the new brand for textile recycling, TRUECYCLED. Through the company’s machinery expertise and technological know-how, they empower customers to produce premium-quality sliver while turning waste into value.

Trützschler Card Clothing; superior yarn quality, longer operation time

Trützschler Card Clothing (TCC) will present a wide range of technologies from its clothing portfolio, covering the full spectrum of applications in the spinning and nonwoven markets. One focus will be on SUPERTIP, which stands for clothings with enormous durability, great variety and highest precision through which excellent yarn quality and a significant added value due to longer operation time can be achieved. With a strong focus on recycling applications, TCC will also highlight its contributions to promoting sustainability within the textile industry.

Textile machinery manufacturer Trützschler Group SE headquartered in Mönchengladbach, Germany, is divided into four business units: Spinning, Nonwovens, ManMade Fibers, and Card Clothing. The machines, installations and accessories are produced and developed in ten locations worldwide. Service companies in Türkiye, Mexico, Uzbekistan and Vietnam and service centers in Pakistan, Bangladesh and Indonesia provide customer proximity in key regions for the textile processing industry.