Designing and developing a wide range of solutions for fabric preparation and finishing, Biancalani Textile Machinery continues to highlight new strategies regarding the textile industry at ITMA 2023. The company centered on Italy showcased two high-efficiency solutions, one for washing and wet treatments (AQUARIA®), and one for drying and tumbling treatments (AIRO®24 DUETTO) at their booth. Regarding processes such as eco-bleach, organic washing (scouring), and washing after-print, Biancalani enables manufacturers to optimize their strategy on sustainability by reducing energy consumption with ecological innovations.

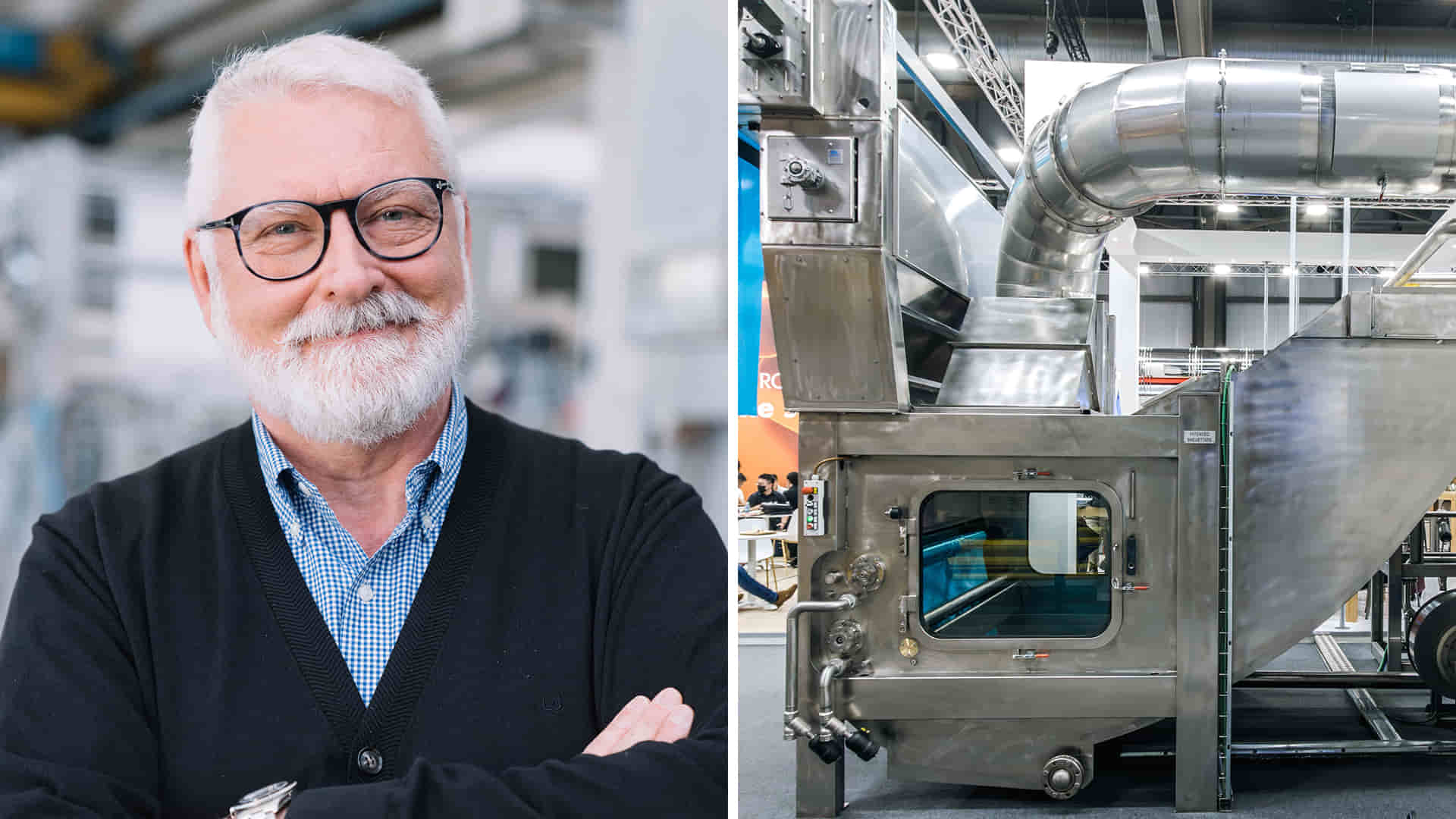

CEO of Biancalani Textile Machinery Rossano Biancalani noted that the visitors demand cost-efficient and environment-safe treatments and their solutions aimed at responding to these needs. Evaluating the experience of ITMA 2023, Biancalani emphasized that visitors showed huge interest in the company’s quality solutions for fabric preparation and finishing.

Biancalani Textile Machinery supports sustainability with eco-friendly innovations

Regarding sustainability as the main concept of ITMA 2023, Rossano Biancalani stated that Energy efficiency has a significant impact on carbon footprint, and thanks to their advanced technology and innovative solutions they are able to make a difference in the textile preparation and finishing industry. Among the main features of the company’s solutions are emphasized as responding to new needs of energy efficiency, reduction of consumption and environmental impact, and a high ratio between productivity and occupied space.

Making an emphasis that they are already at an important point in the process of updating their production process, which will lead to a near-zero impact on the production of their machines, Biancalani explained their focus on environment through new strategies: “As for the open-width continuous drying and tumbling system AIRO®24 DUETTO, by increasing the machine efficiency, we have further reduced the specific energy consumption, while the technology that combines mechanical action with long and variable dwell times for the AQUARIA® continuous open-width washing range has allowed us to minimize the use of water, the most important resource we have available on our planet.”

He also pointed out that AQUARIA® and AIRO®24 have been awarded the Green Label after having successfully passed all the exams. Adding that The Green Label aims to identify the energy and environmental performances of textile machinery and make them easily recognizable and comprehensible, Biancalani said: “During the tests certified by RINA and ACIMIT, the mentioned machines patented by Biancalani were able to easily impress by their process efficiency of 95% and the energy & environmental performances.”

“Turkish textile industry is not only a market but also a strong partner”

Biancalani Textile Machnery’s booth has been visited by numerous visitors from all over the world, especially Türkiye. The company continues to strengthen its presence in Türkiye with the support of Teksel Tekstil standing as their representative and partner. Rossano Biancalani remarked that The Turkish market for Biancalani has always been on the rise, despite periodic fluctuations and they expect this trend to continue in the future. He evaluated the interest of Turkish visitors: “For many Turkish customers, the possibility of carrying out special treatments that include washing and drying in a single production line has been decisive and, in some cases, a determining reason for purchasing. Türkiye is of course one of our most important markets due to geographical and commercial proximity. Beyond that, our ties with the Turkish textile industry are much stronger and deep-rooted. I can easily say that we are in a partnership relationship. We are grateful to work with strong local partners who are of great support in every corner of the globe.”

Saying their strategic choices have been correct, and create excellent prospects for the future, Biancalani disclosed: “Getting continuous input fuels our enthusiasm and gives us the right energy to keep on developing revolutionary solutions for fabric preparation and finishing which meet or anticipate new market needs.”