Uster Technology, one of the leading brands in quality management solutions from fiber to fabric, will introduce the latest product for fabric inspection, Uster Fabriq Assistant at ITMA 2023. Visitors to the company’s booth B103 in Hall 10, will discover this central platform for automated processing, analyzing, and visualizing quality data from Uster fabric inspection systems. The real difference AI Classification makes will also be demonstrated during the exhibition and visitors can take a challenge against Uster AI by trying to classify as many fabric defects as possible in a certain time.

Experts at Uster developed Fabriq Assistant, which is one data platform, as a central quality hub for all stakeholders in the mill, for users to experience the full power of the data being gathered. The new Uster Fabriq Assistant eliminates manual data processing and speeds up decision processes significantly. Fabric manufacturers can release their product for delivery automatically based on their specific business rules without any human in the loop, which eliminates bottlenecks and increases productivity.

Automated collection, analysis and visualization with Uster Fabriq Assistant

Fabriq Assistant, a web-based tool with individual user accounts and specific dashboards, shows a summary of quality performance from all the fabric rolls ever inspected in the mill. Information is presented – and easy to be shared with other users – as a variety of statistical analysis tools, with results in different charts, histograms or evolution trends.

This depth of analysis goes way beyond what previously could only be done manually in MS Excel. Automated data collection, visualization and analysis, as well as data processing and reporting functions, are viewed on the central data platform. It works like an expert assistant, offering the relevant quality data during and after inspection. If the user is searching for information on a specific roll, for example, just a few clicks will bring up the review dashboard. Here, all the details for that single roll are available – including defect images, defect map and list and roll statistics.

AI power in quality management

Fabriq Assistant removes the unwanted workload of manual data preparation and analysis. It also provides the basis for maximum decision-making accuracy, using advanced technologies such as Artificial Intelligence (AI).

Automated features let users experience this highly flexible and customizable application as their virtual everyday assistant, enabling them to be more efficient and productive. An additional effect is increased process accuracy and security, through consistent quality decisions for grading of quality levels, post-processing, delivery release, and, most of all, avoiding claims.

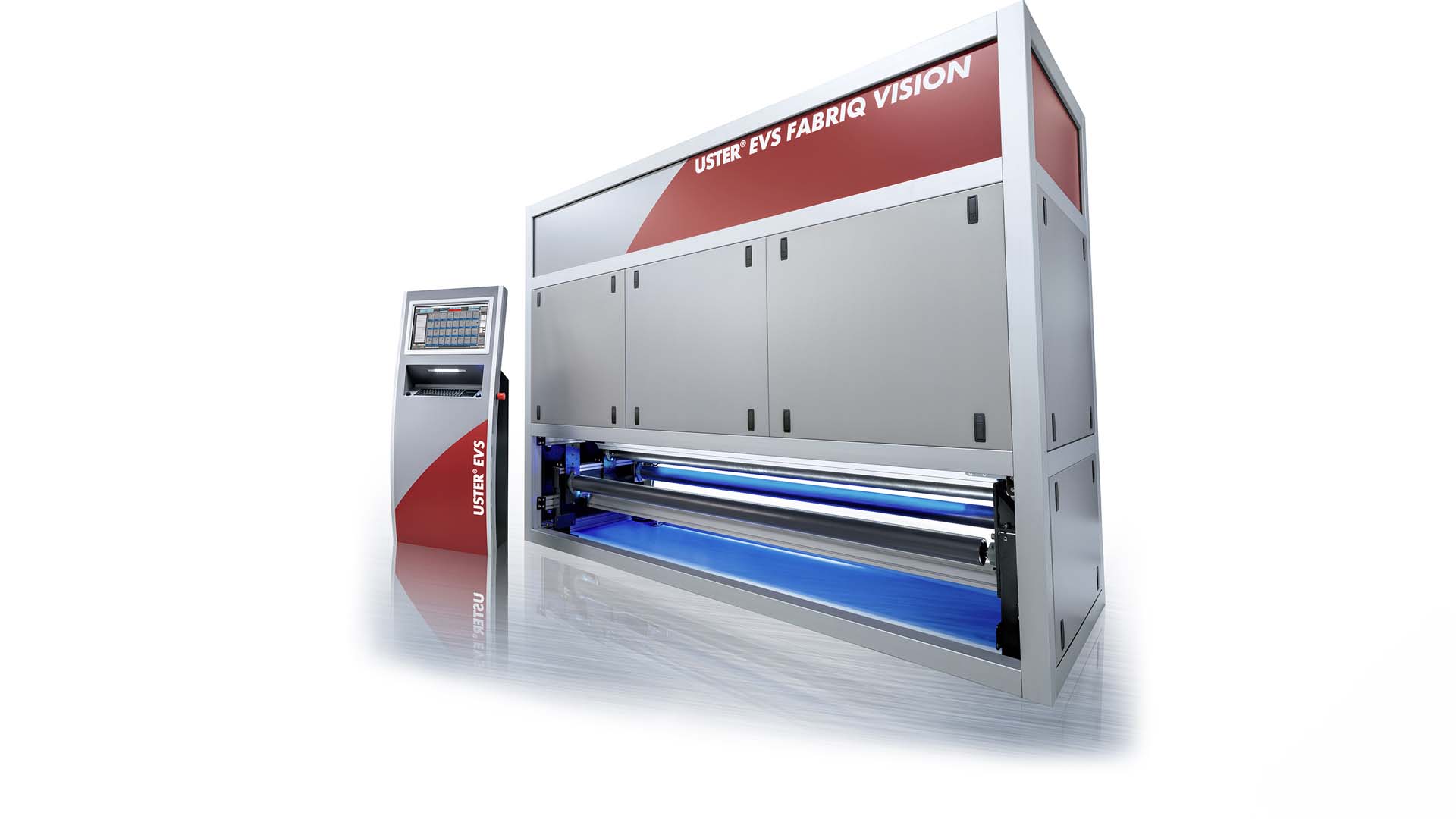

Cutting-edge hardware generates the data to build a reliable foundation for decisions. Uster Fabric Inspection systems offer automatic real-time quality inspection. They can be seamlessly integrated into production – at line running speeds up to 1,000 meters per minute – providing consistent and efficient defect detection.

The core value module introduced with Uster Fabriq Assistant is AI Classification, which extends the application scope of data generated by Uster automated fabric inspection systems. Specific codes can be automatically assigned to every image generated by Uster Fabriq Vision and Uster Fabriq Vision N. Without AI Classification staff members have to laboriously add defect image codes at the PC to perform a data review. By introducing machine learning capabilities, data classification is fully automated and fabric producers can save more than 80% of their manual review time.

Knowing the capabilities of artificial neural networks, Uster Technologies has also introduced safety mechanisms to track the performance of AI. Thus, data can easily be prepared for AI improvements. Uster experts will welcome its visitors to provide more information about what AI can do for fabric producers at ITMA 2023.