Uster Technologies, a provider of quality management solutions from fiber to fabric, is preparing to launch the new edition of Uster Statistics, a globally-accepted quality benchmark and the foundation for industry-wide quality improvement for 66 years. The Uster Statistics 2023 edition includes for the first time a section for recycled yarn and features an extended range of fiber data, supporting sustainability goals. While an ideal fiber mix, with or without recycled content, also ensures meeting quality requirements for least waste, fiber graphs will be newly available for every process step.

The European Union has defined a strategy for sustainable and circular textile production, to make the sector greener and more competitive. Part of this 2030 Vision for Textiles calls for all textile products on the EU market to be durable, repairable and recyclable – and largely made of recycled fibers. Many leading retailers are also championing the use of recycled materials from 2030 onwards. The use of mechanically recycled fibers in spinning has specific quality considerations: such fibers have a higher short fiber and nep content and may often be colored, particularly if post-consumer material is used. Recycled yarns have also limitations in terms of fineness. Officially, a yarn can only be branded `recycled´ when spun with more than 20% recycled fibers. This is set by the Global Recycled Standard (GRS), a voluntary product specification for tracking and verifying the recycled content of materials in a final product.

Uster Statistics 2023 will guarantee the quality of yarn blends of virgin and recycled fibers

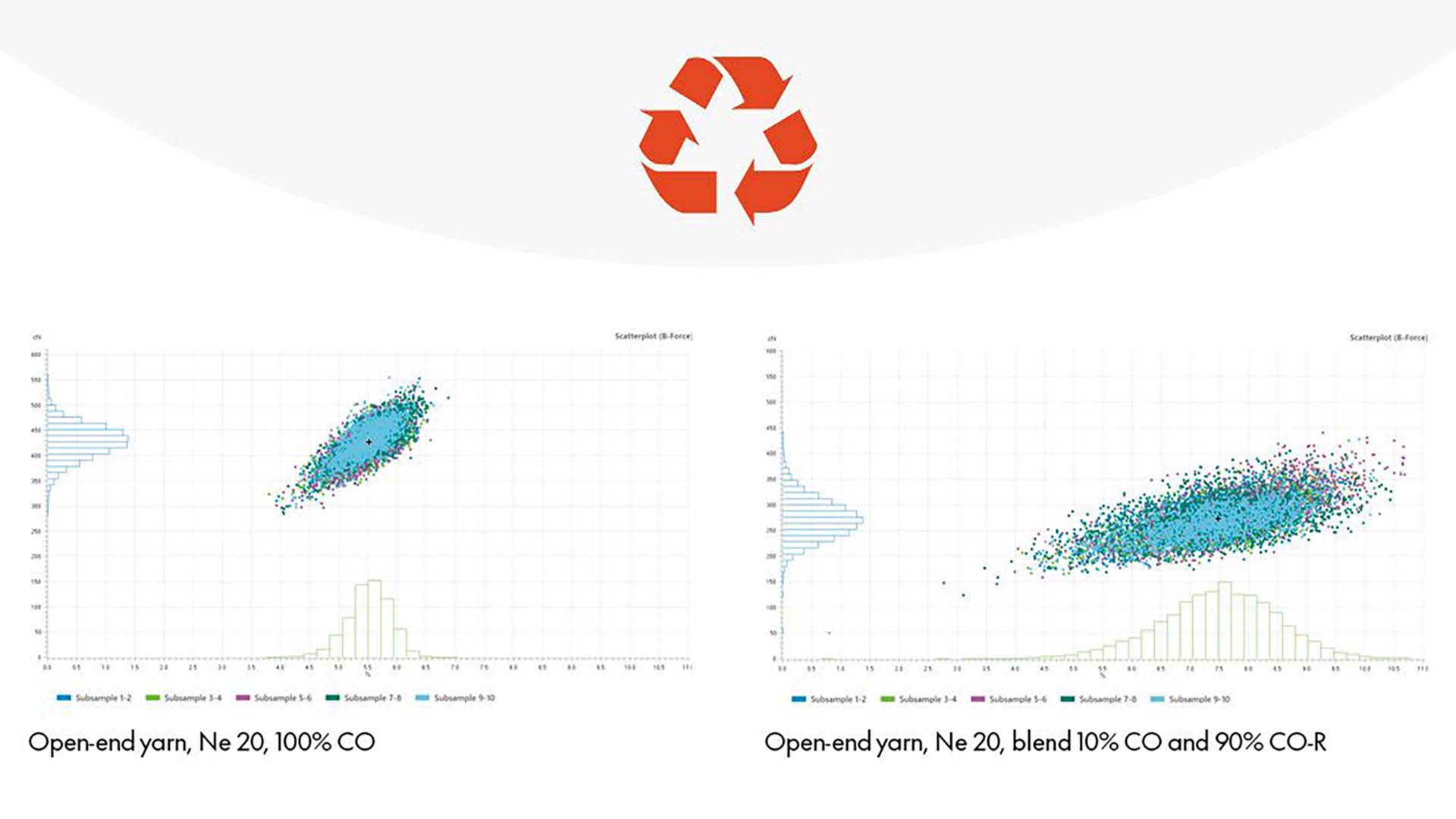

However, spinning yarn blends of virgin and recycled fibers is a much bigger challenge than any other commonly used blend, the results can still be acceptable with comprehensive quality testing, know-how and experience. The use of recycled cotton in a blend with new fiber will impact on both the overall yarn strength and its CV% and even the most sophisticated spinning machinery can be insufficient to fix the problem. Awareness of the risk of yarn quality deterioration with recycled fiber blends means that quality control is the only way to assure customer satisfaction. When spinning new materials, Uster strongly recommends taking both numeric test results and graphic evaluations into account, to eliminate the risk of problems in further processing.

Spinners face major difficulties because of the high proportion of short fibers in recycled cotton (CO-R) and the fact that, when mixing with virgin cotton (CO), the fiber length distribution is sometimes suboptimal. This results, for example, in incorrect guidance of short fibers in the drafting system and potential draft errors. In tests, a Ne 20 rotor yarn of 75% CO and 25% CO-R was compared with a 100% cotton yarn. The values for evenness, imperfections and hairiness were measured and produced a CVm% of 22% in Uster Statistics, which might appear to indicate excellent quality for the recycled yarn if relying on numeric values alone. In fact, closer analysis with Uster Tester spectrograms showed a draft error at the draw frame. In this case, the problem was detected before causing an uneven structure in the subsequent fabric made from the yarn.

Common language for better communication

It is an unavoidable fact that blending virgin and recycled cotton will make some quality parameters worse. Using recycled fiber is often desirable, but it creates a new reality for the industry. To cope with the risks, better communication and a common understanding are needed throughout the textile value chain. Uster’s common language of quality will play an important role in improving communication throughout the textile industry.

Spinners need to find a way to transform their mills to a more sustainable future and already have the tools they need, allowing them to benefit from both laboratory instruments and quality monitoring systems to optimize quality and productivity. Their experience, combined with Uster knowledge and latest technology in quality control and analysis systems, are a promising basis for a sustainable future for the textile industry.