Uster, one of the leading manufacturers of test and quality management systems in the textile industry, will introduce its effective solutions for spinning mills in the countries in the region, especially in Uzbekistan, at CAITME 2022 on September 7-9. The company, which will host its visitors at booth J82 in pavilion 3, invites textile professionals to gain an understanding of how three monitoring and testing systems make a huge difference individually and change the world of quality management in spinning mills when combined. Visitors will have the opportunity to get first-hand information and advice from their experts at the exhibition or from Art Textiles representing Uster at CAITME and to examine and explore Uster systems closely. In addition, Uster invites those who cannot attend CAITME to its virtual showroom.

Connecting Uster Tester 6 with USTER® JOSSI VISION SHIELD N and Quantum 4.0 results in Total Contamination Control, allowing spinners to manage remaining contaminants in yarns at the lowest possible cost. The Alarm Center, on the other hand, creates another Value Module that fully matches this trio.

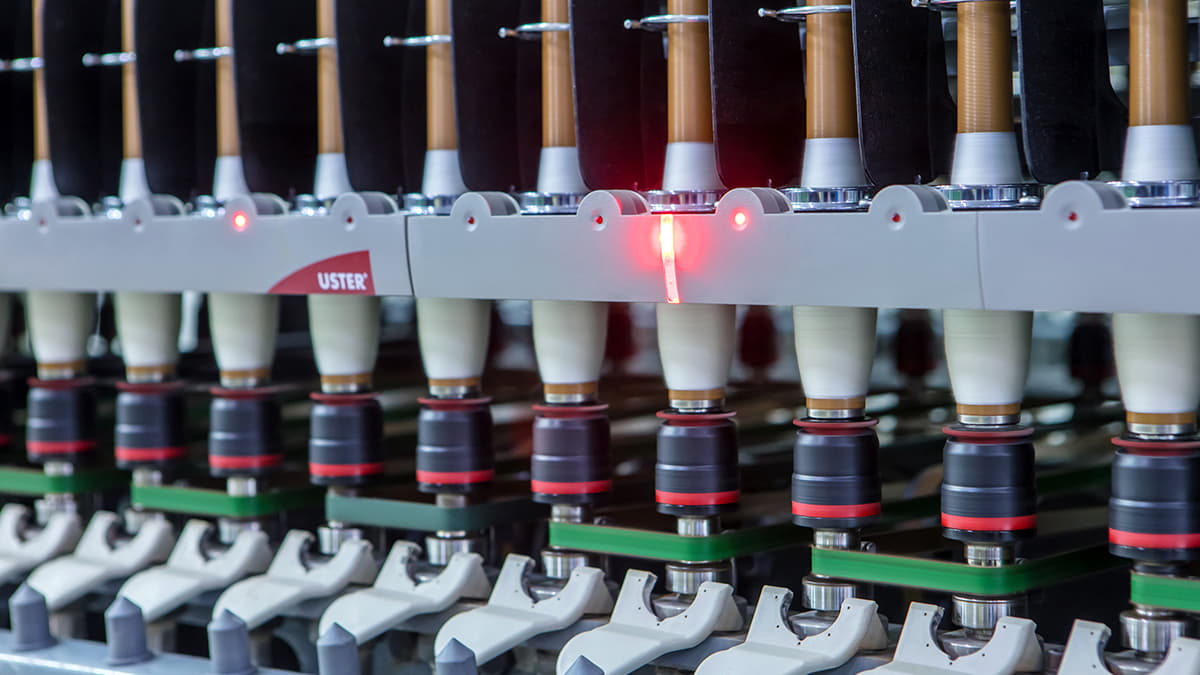

Uster systems join forces for yarn quality control

Uster Tester 6 helps spinners achieve better productivity and profitability and features Uster Quality Expert, linking accurate laboratory testing with data from in-line systems such as Uster Quantum 4.0. The system can be used in all kinds of sliver, roving and staple yarn and can also be used in the measurement of special yarns such as slub and conductive yarn.

USTER® JOSSI VISION SHIELD N is ideally positioned right behind the fine opener on the production line to identify typical types of contamination in nonwovens, including coloured fibres for best detection results. Fibre bundles are allowed to pass through spectroscopes in their most open state in this way. Moreover, the slim design of the fibre cleaner fits well into existing lines, easily copes with the high output of standard lines, and is therefore easy to install.

The Uster Quantum 4.0 yarn clearer, providing comprehensive security, error prevention and flexibility with both capacitive and optical sensors, works intelligently with an innovation known as Cross Clearing. This finds and eliminates hidden defects through double checking, in which the main sensor signal is supported by the assistance sensor. It deals with factors such as humidity variations as well as issues that can cause breaks downstream, such as unnoticed fluff events.