Carpet and rug weaving technologies specialist Vandewiele will host weavers from Türkiye and the world at the ITM 2022 to be held in TÜYAP, Istanbul on June 14-18. Vandewiele Turkey, the company’s subsidiary in the Turkish market, will exhibit numerous traditionally woven carpets on the RCE+ carpet weaving machine at its booth number 215A in Hall 2. Visitors to the exhibition will also have the opportunity to examine the digitally controlled RCF machine with Fast Creel, cut-loop machines and specific machines for weaving light carpets, as well as the carpet samples. In addition to combinations of cut pile carpets with flatweave and sisal look carpets, the highest carpet qualities in reed 1000 d/m 10 colours, 1200 d/m and 1500 d/m with up to 5,000,000 dots/m² will be shown.

Vandewiele will present the Colortec 1/10” tufting system to the visitors at ITM 2022. The system developed by digital control of pile yarns (active yarn feed, also called IPD) and competing with traditional Axminster carpet machines, has a high resolution in 8 colours or 1/7” gauge. In the finishing segment, the new autonomous shearing machine ATSH will be exhibited by Bejimac at the Vandewiele booth, where numerous machines for plain carpets, artificial grass and tiles and other applications will also stand out.

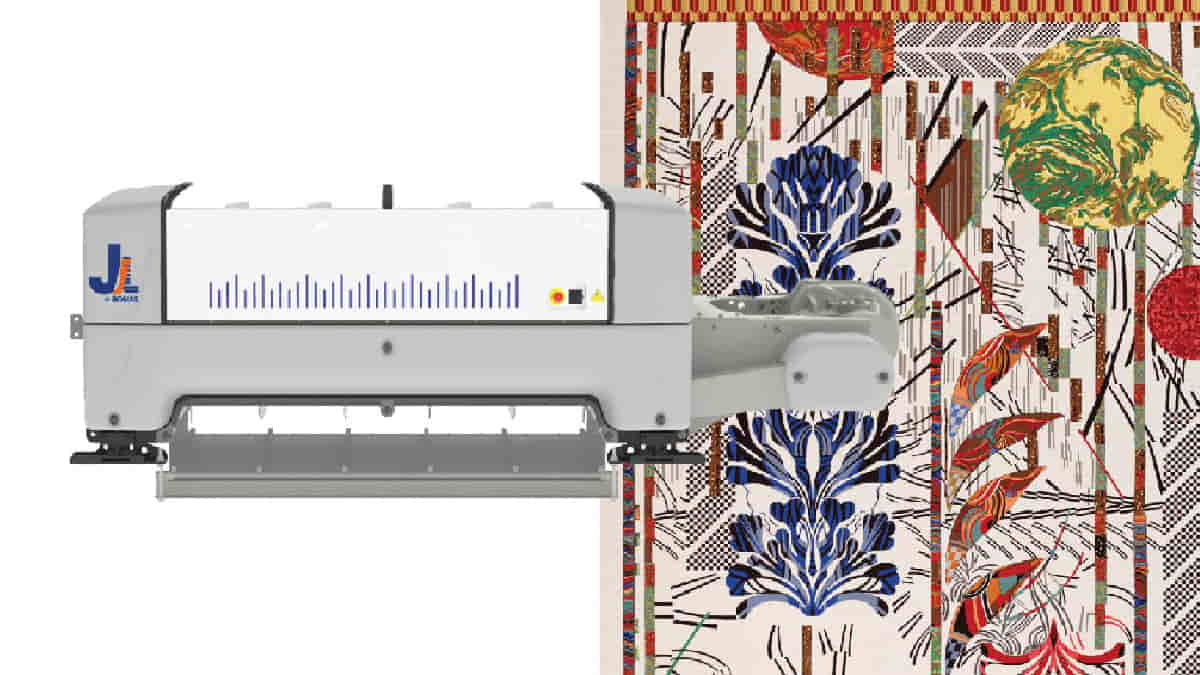

Vandewiele will present its newest addition to the Bonas JI range of jacquards at ITM

Vandewiele’s newest addition to the successful Bonas JI jacquard range, JIL, will be presented to visitors during the exhibition. The JIL represents the logical extension of the JI range allowing the customers higher hook capacities within the same range of machines. While hook capacities up to 11520 are possible within the JI range, the company also offers the SI machine going up to more than 31000 hooks in a single machine if even bigger capacities are required.

A Picanol Optimax 190cm loom using their special superstructure will also be demonstrated at Bonas JIL’s Vandewiele booth at ITM 2022, providing a very compact installation with a much lower roof height than classical gantry installations. 9600 hooks of JIL weaving furnishing fabric with a full repeat design will be shown during the exhibition. User-friendly and practical controller software will also be presented alongside the loom.

DHS3 line offers an unequalled level of evenness in heat setting

Superba, Vandewiele’s brand that offers advanced heat-setting solutions, will be at the exhibition with its hot-air heat-setting DHS3 line. This three-layer heat-setting process adds an unequalled level of evenness and a highly homogeneous fixation characteristic to the yarn, as well as stain resistance or enhanced bulk and offers high energy savings in reduced floor space.

Another Superba product to be exhibited at ITM 2022 will be the B403 automatic winder, which expands its area of application beyond the carpet yarn field. The B403, marking a real technological breakthrough with its individual spindle motorization drive, enables a constant tension winding process, as well as an accurate bobbin length measuring and unique quality control for each yarn position.

In addition to these, the BXE extrusion line from VANDEWIELE, the MF400 texturizing machine and the MCD3 space-dyeing machine as complementary processes before heat-setting will take place at ITM 2022 with SUPERBA lines. Customers also benefit from the possibilities of digitalization with Vandewiele machines, which can be connected to the ‘TEXconnect’ supervision system through cloud computing to comply with the Factory 4.0 concept.