Itema, one of the worldwide leading manufacturers of advanced weaving solutions, introduced the mechatronic device iSAVER, which enables cost-saving to denim weavers, at the Denim Première Vision held in Milan on October, 13-14. The device saves 1,000 kg of cotton per loom per year, thus preventing the waste of approximately 20 million litres of water. 100% made in Italy, iSAVER® is already present in the biggest denim weaving mills in China, Vietnam, Turkey, Egypt, Italy, and South America.

Denim, one of the most popular fabrics in the world with 3.5 billion garments produced each year, has a very strong environmental impact. The denim manufacturing process consumes around 35% of world cotton production and moves a global market reaching 21.8 billion dollars in 2020. It is estimated that 3,800 litres of water and 18.3 kWh of electricity are required to produce a single pair of jeans, generating 33.4 kg of CO2 emissions over the entire life cycle of the product.

iSAVER: more savings, lower environmental impact

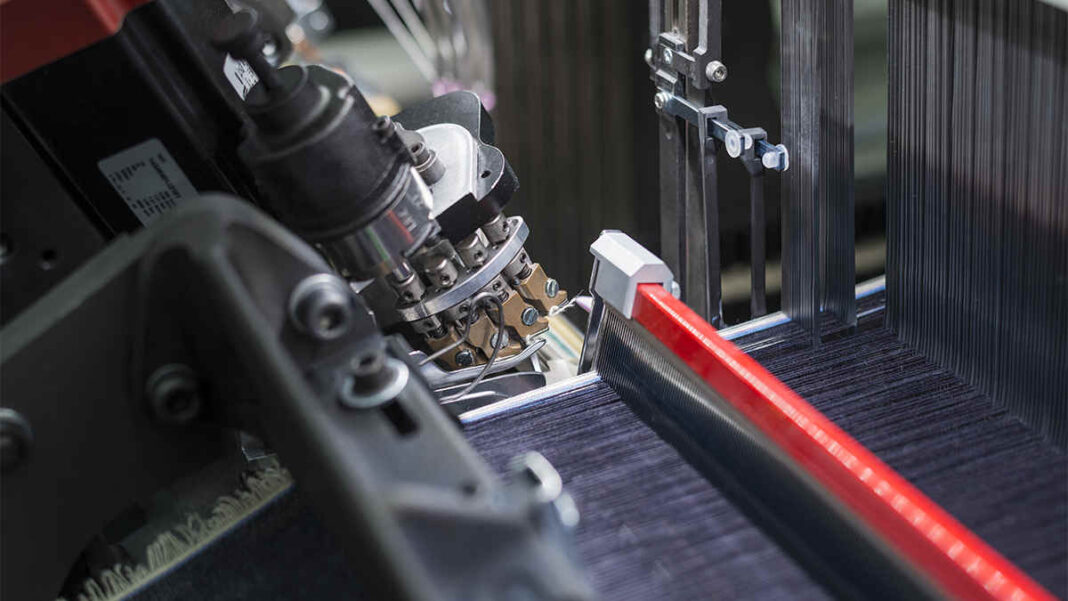

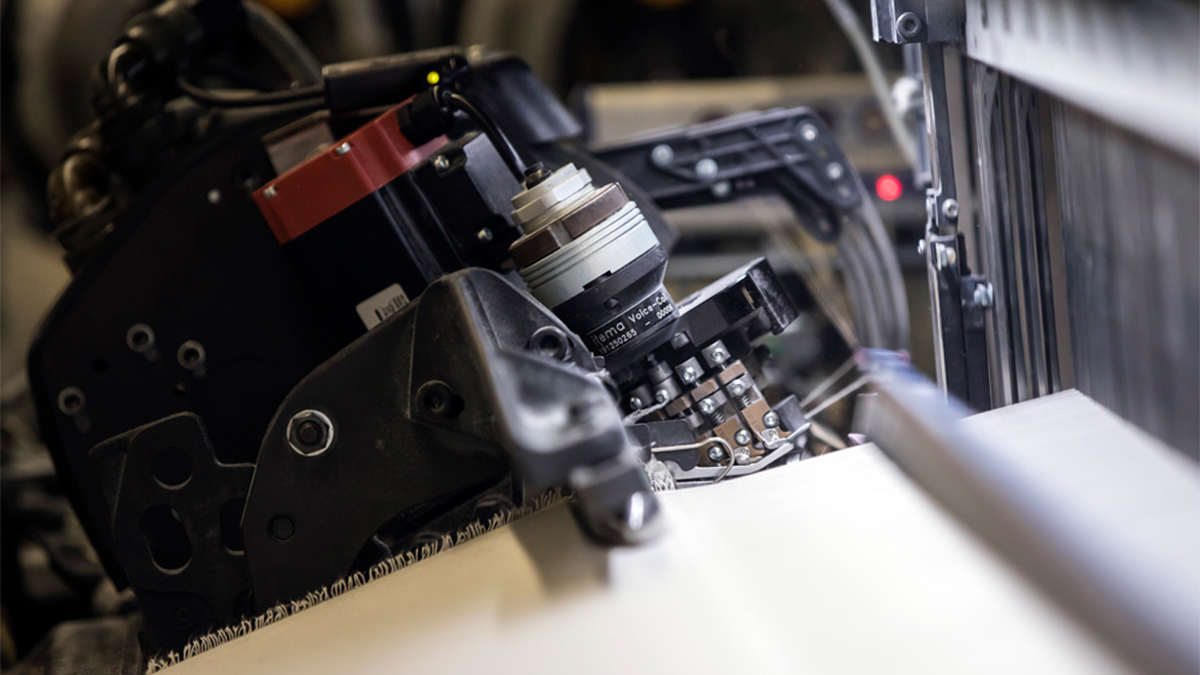

Working up to four weft colours/yarns, the iSAVER contains four small clamps that hold the yarn during the weft insertion cycle and move according to the weft that needs to be inserted into the fabric. The device inserts the weft yarns into the fabric without the need for additional yarn and eliminates the false selvedge on the left side of the fabric. Thus it significantly reduces the waste of raw materials and water.

Saving at least an average of 2 thousand Euros per year per machine, iSAVER is based on the latest and most advanced mechatronics principles. This provides weavers with a highly innovative yet intuitive and easy to use device where setup is possible directly from the machine console. In addition, the device does not hinder in any way the operating speed of the weaving machine.

The iSAVER stays in its position since the weaver needs to work on the right side of the fabric by setting an asymmetric width reduction. The device has been designed and developed by Itemalab®, the Itema Group company located inside the Kilometro Rosso Innovation District in Bergamo, employing around 70 engineers and experts.

It makes a difference in the market

Itema Group CEO Ugo Ghilardi stated that the entire textile supply chain is constantly looking for ideas and solutions to increase the sustainability of production processes by developing technologies and processing systems to reduce waste, water and electricity consumption. Saying that with iSAVER, they have brought a perfect solution to the market, which makes the difference as it allows denim weavers and fashion brands to offer a finished product with a much lower ecological footprint Ghilardi noted: “Thanks to the uniqueness of our technology and its contribution to sustainable denim production, we are the only textile machinery manufacturer to participate in Denim Première Vision as a participant”.

“We save 650 kg to 900 kg of waste yarn per year with iSAVER”

With the launch of iSAVER, a new benchmark has been set for sustainability in denim fabric production, which meets the requirements of the most renowned fashion designers who want to focus even more on sustainable fabric manufacturing. In addition, iSAVER is one of the main features of the rapier weaving machine Itema R95002denim, which is designed to offer weavers superior textile quality, superior user-friendliness and tangible energy and raw material savings. The user of Itema R95002denim and iSAVER, Sharabati Denim General Manager Nehad Set Alyaman, said that iSAVER has been a wonderful and impactful innovation that significantly reduces production waste in weaving. Alyaman stated that they has led to never-seen before cost savings, allowing them to save from 650kg to 900kg of waste yarn per year.