Mattex will exhibit Kornit Digital’s latest sustainable printing solutions at its booth 9-C20 at Fespa Eurasia 2021, which will be held at Istanbul Expo Center on December 2-5. At the Mattex booth, visitors will have the opportunity to closely examine Kornit Digital’s machines and inks that offer sustainable production with zero water consumption. Matset A.Ş. Sales Manager Burak Kaftanoğlu explained the details of Kornit Digital solutions that will be at the booth and Kornit-Mattex cooperation to Textilegence.

Burak Kaftanoğlu said that Mattex’s mission is to provide industry professionals with high quality, economical and, most importantly, sustainable printing technologies with low energy and water consumption. Noting that the Mattex-Kornit cooperation started in 2021, Kaftanoğlu stated that Kornit’s machines equipped with HD technologies received full marks from industry professionals with their low ink consumption. Kaftanoğlu disclosed; “We believe that our market, which is in a growth trend even during the pandemic, will prefer Kornit products in 2022”.

Kornit Digital DTG and DTF solutions will be at the Mattex booth

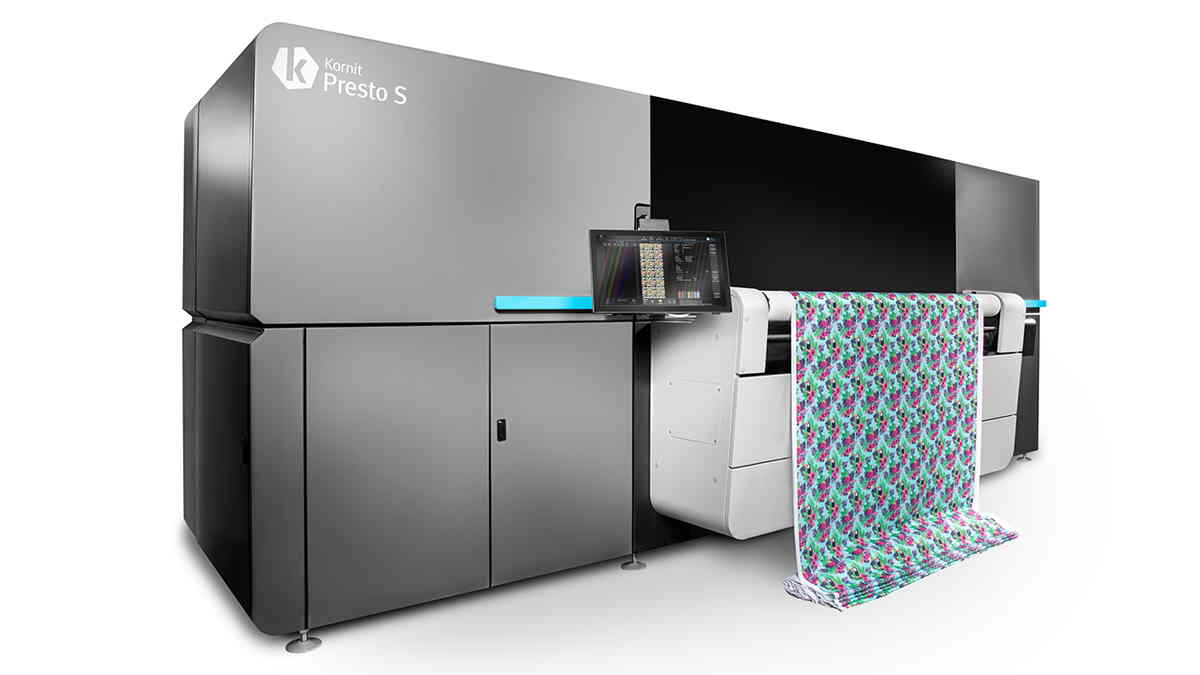

Saying “Kornit Digital products are used primarily by manufacturers offering textile and promotional products and retailers selling online. We hope that we will meet with those manufacturers who produce with traditional printing methods and are considering transitioning into digital printing, as well as those who want to produce on demand at Fespa Eurasia,” Kaftanoğlu said that Mattex will attend the Fespa with Kornit Atlas DTG (Direct Printing on Garment) printer and Kornit Presto DTF (Direct Printing on Fabric) printer, Kornit Neo Pigment inks will also be at their booth.

Application-specific printing solutions

Burak Kaftanoğlu stated that the Kornit Atlas DTG printer is suitable for both sample and high-volume production and explained its prominent features as follows; “It is unrivalled in its class with a production capacity of 200 pieces per hour for light-colour clothing and 160 pieces per hour for dark-colour clothing. Manufacturers can directly print on a wide range of products with Kornit Atlas’ multiple pallet options. The printed products are used safely thanks to Kornit NeoPigment Eco Rapid inks, which have GOTS and Oeko TEX certificates,”.

Emphasizing that there is no need for external pre-treatment or post-processing when printing with the Kornit Presto DTF printer equipped with Kornit Neo Pigment Robusto inks, Kaftanoğlu stated that this is the most advanced solution for printing directly on any type of fabric in one step. Kaftanoğlu; “With Presto, the ready-to-print fabric becomes ready for cutting and sewing after printing. Thanks to the softener built into the machine, a perfect touch is achieved on all kinds of fabrics”.

Common platform for e-commerce: Custom Gateway

With the demand for on-demand production and e-commerce becomes prominent day by day, Kornit Digital launched the Custom Gateway platform a year ago to support the e-commerce efforts of manufacturers. Stating that Custom Gateway is a cloud-based software platform for the sale of personalized or print-on-demand products, Burak Kaftanoğlu said that manufacturers and brands are included in the common workflow by taking part in this platform.

“We see in the meetings we hold that Turkish manufacturers want to be on this platform. We believe that our users will start using this platform in 2022,” said Kaftanoğlu, and added that thanks to Kornit Digital’s MAX technology, which is especially suitable for tailor-made production, users who can print embroidery effect in addition to their standard production will be at the forefront with a wide variety of production in the fashion and ready-to-wear sector.

Manufacturer specific investment research

Stating that Kornit Digital products are in a competitive position, Burak Kaftanoğlu noted that the main reason for this is that the company can produce both samples and volumes with few people. Kaftanoğlu; “After the demo work we do with the manufacturers, we carry out ROI (Return on Investment) studies in direct proportion to their expectations. Our ROI studies cover a lot of data, including cost and production expectations. Investment decisions are taken after this special study for the manufacturer”.