ITMA Asia + CITME was postponed to this year due to the pandemic. It will be held at the National Exhibition and Convention Centre in Shanghai on June 12-16. Approximately 1,650 participants from 24 countries are expected to attend the event, which will be closely followed by the global textile industry. Groz-Beckert will also take place at the fair and will introduce its innovations in the knitting, weaving, felting, tufting, carding and sewing product segments.

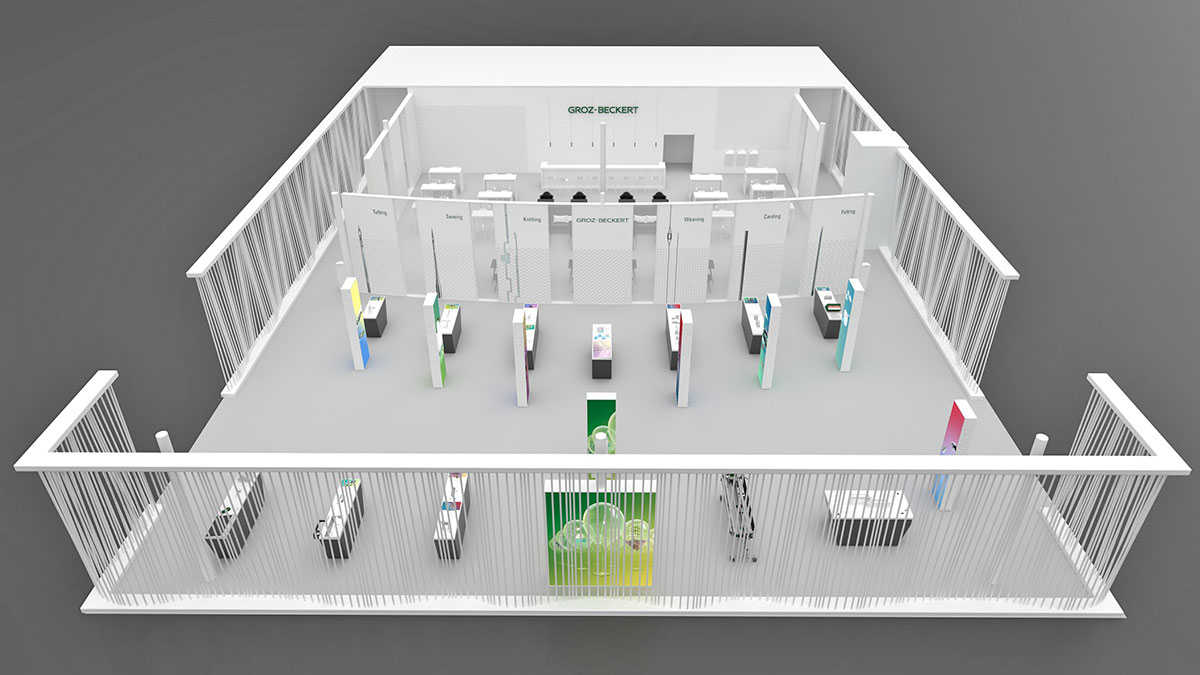

The company will take place at booth C31 in Hall 4 and will create its virtual booth for participants who cannot physically visit the fair too. While Groz-Beckert will exhibit many of its solutions directly, it will also make it possible to view its products in three dimensions with the augmented reality. Visitors will be able to stroll through the virtual space alone or move with a Groz-Beckert employee. Those who want to attend the digital trade fair must register for free about two weeks before the fair.

Even and error-free warp knitting

Groz-Beckert will demonstrate its importance as a system provider in warp knitting, as well as presenting its new products from the knitting segment at ITMA Asia. The innovations to be exhibited in this segment at the fair are as follows: SANTM SF staple fiber needle; SNK SF staple fiber sinker specially designed for use on large diameter circular knitting machines; durTM needle, which is especially suitable for high loads on sock machines thanks to its optimized geometries; SANTM TT for application-specific use in technical textiles for flat knitting machines and a needle for achieving new fineness dimensions in flat knitting.

While fully compatible warp knitting machine needles and system parts provide an even and error-free warp knitting process, augmented reality provides deeper insights into the interaction of individual system components.

The optimal solution for weaving: WarpMasterPlus

Groz-Beckert offers the most optimal solution for every weaving mill with the new WarpMasterPlus in the weaving segment. All the features of the proven WarpMaster concept are demonstrated in detail using a 3D model and augmented reality. The miniature weaving mill illustrates the interaction of all products in the field, from cleaning machines and weaving accessories to the KnotMaster.

The patented GEBECON® felting needle provides numerous advantages to the manufacturer

The patented GEBECON® felting needle stands out in the felting product segment. Offering an improved surface quality and optimized bending resistance, the product provides many advantages to users. Some advantages such as know-how protection and improved needle logistics will be highlighted at the fair.

Groz-Beckert’s tufting solution ensures quality and economic results

Visitors to the tufting product area will have the opportunity to explore the measurable advantages achieved during the production of tufted floor coverings using Groz-Beckert Tufting Gauge Part Systems. The coordinated combination of materials and the functional interaction of all tools guarantee the quality and economic results of the tufting process.

New stationary flat series in the carding segment

Groz-Beckert will present further developments for the spinning industry in the carding product segment at the fair. Among these are the new stationary flat series, TV56 revolving top and the cylinder card clothing with special tooth geometry. The new stationary flat series stands out with an innovative tooth geometry and a new kind of tooth distribution. Featuring a new setting pattern and 560 points per square inch, the TV56 revolving top makes cleaning easier. As for the improved cylinder card clothing, it offers an impressive solution with its special and patented tooth shape, which has a positive effect on maintenance. It provides an ideal use especially for quality-oriented cotton spinning companies producing high-quality yarns.

Even seam pattern in multi-directional sewing

The sewing exhibition will focus on technical textiles and, in particular, the manufacture of car seats. Groz-Beckert’s SAN® 5.2 special application needle answers the high demands when sewing car seats. While the special geometry provides it sufficient stability; The double groove in the point area improves thread guidance and offers an even seam pattern, especially in multi-directional sewing processes. The scarf chamfers on both sides of the needle prevent skipped stitches and optimize loop formation. The GEBEDUR® titanium nitride coating increases wear protection. The Sewing customer portal, which includes the functions and content of the products, stands out as another digital service offered by the company.