Spinning, twisting, cabling and automation solutions expert Saurer is getting ready to exhibit its latest innovations at the ITMA ASIA + CITME to be held on June 12-16. Saurer meets the increasing demand for cost-effective automation in both the spinning and twisting/cabling factories; and will host its visitors with innovations in many fields.

Saurer enhanced the well-known E3 attributes of the design philosophy, energy, economy and ergonomics; with intelligent technologies which address pressing issues of labour and ergonomics. Visitors to the fair will have the opportunity to closely experience the company’s latest products at booth F01 in hall 8.

Saurer offers new advantages in staple fibre processing with new automation solutions

One of the staple fibre processing solutions to be on the Saurer booth is the new carding machine, Autocard. The machine was developed to create more value in the fibre preparation chain and has a higher carding area. In this way, it provides 18% higher output and cleaner sliver. At the same time, the machine has LED lights for intelligent operator guidance, and can changes are carried out during the entire production without slowing down the speed of sliver delivery.

Zinser Systems’ new generation ring spinning machine, the Z 72XL offers low energy consumption, optimal user-friendliness ease of use and flexible automation solutions for intelligent spinning. The machine comes with a new compact device, the Impact FX pro system. It is designed especially for the medium and fine yarn-count range for yarns with lower hairiness and greater strength. Thus, it provides advantages in weaving and knitting applications.

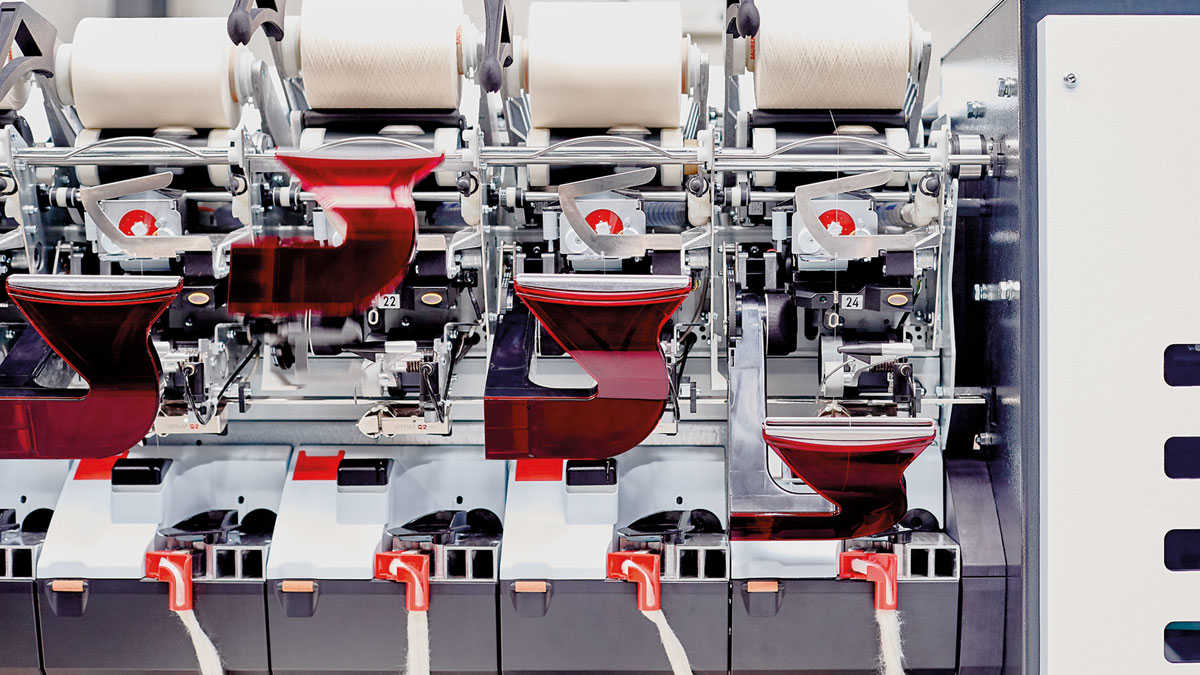

With the Autoconer X6 winder, Saurer is moving towards customised automation in package winding. State-of-the-art RFID technology, sensor-controlled functions and smart control systems enable continuous automation progress. The industry will meet new open prism technology that offers improved splice quality, handling and maintenance.

Low spinning costs, high quality

Schlafhorst Systems’ clever automation solutions for open-end spinning brings together Autocoro 10, Autoairo and AutoBD. Autocoro has seen the sale of 1 million spindles worldwide, while Autoairo and AutoBD will be exhibited for the first time in Asia. The Autoairo air-spinning machine ensures high yarn quality and productivity with low spinning costs. AutoBD offers spinning mills the option to choose the degree of automation and productivity potential of the rotor-spinning machine. In addition, all automation modules can be easily retrofitted. While SynchroPiecing and Multilot enable seamless lot changes, SynchroPiecing also minimizes the need for operators and ensures high productivity even with challenging raw materials. At the same time, users can fully automate the removal of packages and insertion of empty tubes.

Saurer reduces energy consumption in twisting and cabling

The latest generation CompactTwister, the series 8 from Volkmann Systems, introduces important innovations for twisted yarn quality, flexibility and energy consumption. The spindles supplied to the market in millions indicate that this solution is in a leading position in the market.

The 5th generation of direct cabling machine for tire cord and industrial yarns, Allma Systems’ CableCorder CC5 provides users lower energy consumption. It also offers users a smart spindle concept, modern quality monitoring, improved ergonomics and innovative data management. With up to 200 spindles, the CC5 saves a lot of space with the new spindle gauge 400.

Saurer Automation Solutions’ another innovation to the fair will be its palletiser. The company also offers intelligent and individual automation solutions for twisting and spinning mills that increase the efficiency of machine loading and package transportation, providing significant time and cost savings throughout the entire textile value chain.

New digital sensing solutions optimize production processes

The new Shop Floor Senses Element for the mill management system Senses optimizes processes in production plants by reducing the walking distance of machine operators. Users can import all the machines’ production settings into Senses using the Recipe Senses Element. In addition, it can ensure that they are configured to result in optimal production and quality. This guarantees fast and reliable lot changes.

Saurer’s innovation in laboratory equipment, the Autolab ET measures yarn hairiness fully automatically via a modern, integrated laser sensor. Besides determining the overall hairiness, the hair length can also be classified automatically. All relevant parameters for slivers, rovings and yarns are determined with a single testing device, ensuring optimal running behaviour for the spinning machines.

A new solution to demand in air-jet spinning: NO-6270 KN

The new apron for air-spinning in the Accotex product line will also be present at the Saurer booth. While the increase in high delivery speeds in air-jet spinning has led to higher demands on the elastomer components in the drafting system. Saurer has developed the NO-6270 KN apron, a new state-of-the-art compound for air-jet spinning for this problem,

The new high-performance spindle from the Texparts product line with a reduced wharve diameter of 17.5 mm is based on the CS1 S silent spindle-bearing unit. This spindle offers a long service life and operational reliability, running properties up to 30,000 rpm and energy savings. When the Zero Underwinding system is combined with Spinnfinity, it is a perfect match for automated and efficient ring spinning.

Speed increases in filament processing, while noise and energy consumption are reduced

Suitable for yarn running up to 1,000 m/min, the powerful motor-driven texturing units of the Temco product line, the FTS525M have a wide speed range. However, the FTS unit stands out with its lower noise level and energy consumption. Thanks to its high flexibility, the yarn twist direction can be changed easily, while the cooling plate does not need to be adjusted for S/Z production.

CoolFlow Texturing Discs from the Temco product line optimise the air stream and improve heat transfer with the special design of the discs. This results in less swelling as well as a significant reduction in disc load at process speeds of up to 1 000 m/min, thus extending the service life.

In the Fibrevision product line, Saurer will also offer an upgrade option on tension monitoring with the market-leading Fraytec FV1 and FV2 systems for broken filament monitoring in technical and industrial yarns. Depending on the application, it can be easily upgraded with sensor ranges of 0-500g or 0-1000g.

Visitors to the ITMA Asia + CITME technology fair will also have the opportunity to examine the company’s updates and upgrades offers, original parts and clever preventive services at the Sun area, in the Saurer booth. Alongside the digital training opportunity at Saurer Academy, visitors will also be able to learn more about new features on the Secos – Saurer Customer Portal.