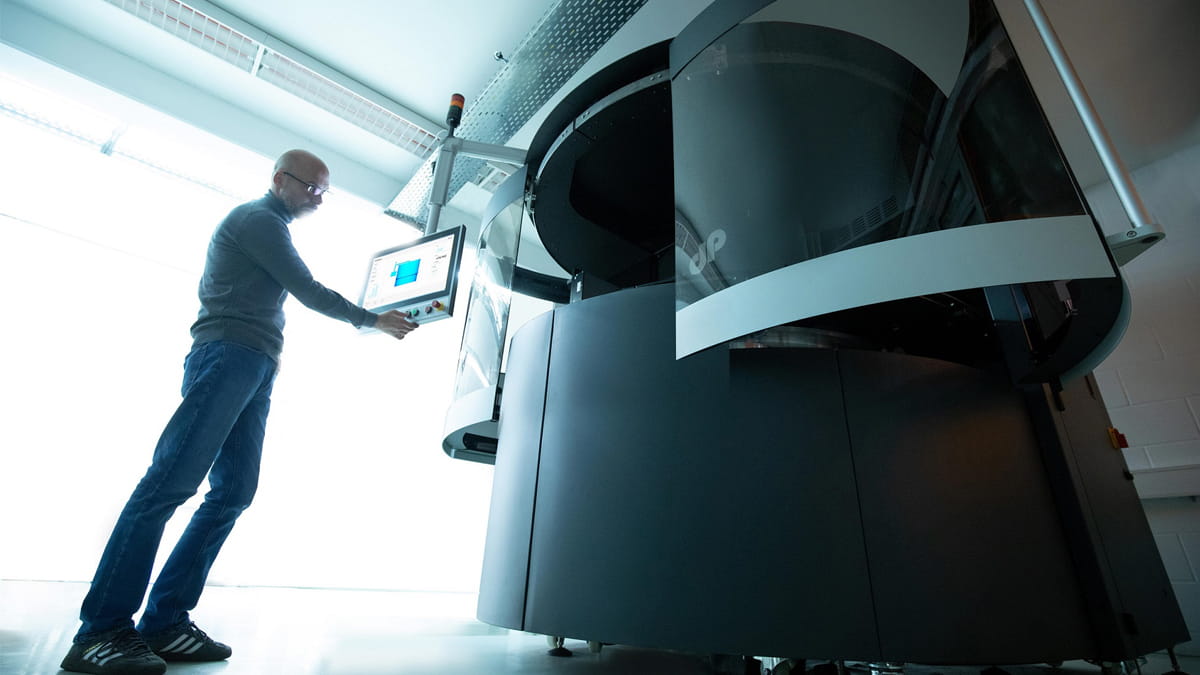

The Xaar 1003 printhead, developed by Xaar for industrial 3D printing, offers the speed, volume and quality that its users are looking for. The Xaar 1003 printhead, located in the revolutionary 3D printing machine AMPolar i2 of dp polar GmbH, a manufacturer of German-based industrial 3D printing (Additive Manufacturing) technologies, enables the system to produce parts on an industrial scale.

The AMpolar i2’s patented Additive Manufacturing process includes a series of Xaar 1003 printheads. In this way, the machine can be produced by jetting parts in a higher volume and at a significantly reduced cost compared to traditional 3D printing machines.

Lower investment and production costs are achieved with Xaar 1003

The highly productive single-pass printing process of AMpolar i2 delivers build volumes of up to 700 litres across its pioneering; continuously rotating print platform. For example, the AMpolar i2 machine is able to produce over 500,000 automotive electronic power-plugs per year; at the lowest costs per part. Achieving the same output with traditional 3D printers would require the operation of multiple machines, requiring substantially more initial investment, and increasing costs and complexity across production.

Hans Mathea, managing director and founder of dp polar said that the AMpolar i2 delivers unparalleled output of printed parts per hour; resulting in a significant reduction in cost per part. Mathea continued saying; “The Xaar 1003 is integral to the machine’s design and performance and the ability to handle multiple fluids means that; 3D Printing and Additive Manufacturing are now a reality for the volume production of parts for many industries.”

Germany based dp polar company designs, develops and presents 3D industrial printing systems; for the automotive, aerospace, mechanical engineering and consumer industries.

3D printing will become more industrial

As part of Xaar’s extensive printhead portfolio; the Xaar 1003 is proving invaluable for the industrialisation of 3D Printing with its speed, reliability and ability to jet a variety of fluids; over an increased viscosity range. This ensures a suitable fit for a wide range of Additive Manufacturing applications.

Mike Seal, Xaar’s Business Development Manager, Advanced Manufacturing and 3D Printheads said; “dp polar’s use of the Xaar 1003 printhead and the innovative design of the AMpolar i2; shows the natural progression of photopolymer jetting from a prototyping technology to a true manufacturing process; a transition we are seeing more and more within functional inkjet applications”. Seal concluded saying; “We are delighted to see the AMpolar i2 utilise Xaar’s printhead technology; and make the volume production of industrial parts through 3D Printing a reality”.