The world’s leading supplier of automation technologies and technical training, Festo invited textile manufacturers to discover more automation and digitalization solutions in textile production at its stand in Hall 7 at ITMA 2019. During the fair, the company explained its automation solutions and components to its visitors and shared its interesting innovations at a press conference.

The Festo booth presented products in 4 main segments, including the solutions that were developed for simple movement needs, which are considered as core technologies. These high quality and attractively priced components have more than 2,200 products and can easily meet more than 80% of the requirements of a textile company. Another focus at the booth was Industry 4.0 solutions. It was shown that the secure cloud path was opened with the IoT gateway CPX-IOT in these products as they include solutions regarding the transition from mechanical system to the cloud.

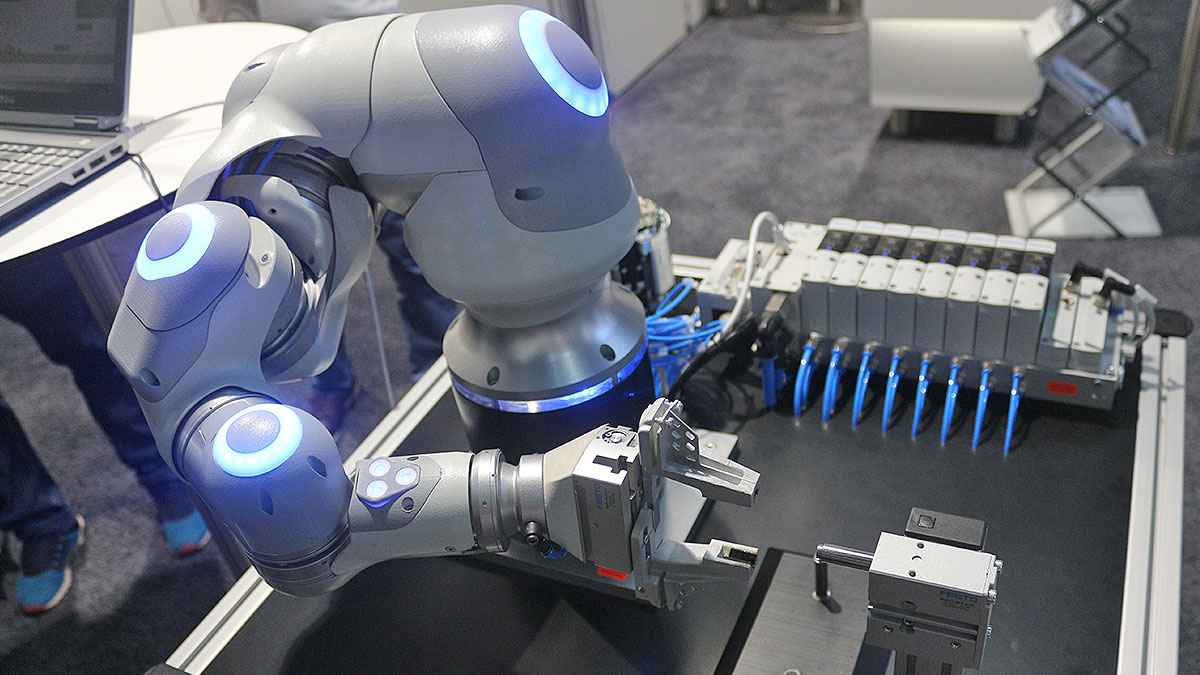

Another forward-looking innovation was the BionicCobot. Robots can be used as assistance systems to perform tasks and ease the load on people, particularly for monotonous or hazardous activities. They are ideal for safe collaboration between people and robots. Another innovative product at the Festo booth was the pneumatic muscle. This product is ideal as a pneumatic spring for precise clamping of warp beams. The pneumatic muscle is a membrane shrinkage system, is a tube that contracts under pressure. This unique innovation combines a flexible tube with fibres and a diamond-shaped fabric for reinforcement and durability.

Festo Automation Stars for Textiles

Festo’s basic product range includes more than 2200 components and aims to respond to the demands of textile manufacturers for more efficient and cost-effective production in the face of increasing competition and decreasing profitability. The company’s Stars in Automation include components within the pneumatic and electrical control chain, from compressed air preparation, valves and cylinders to accessories, such as matching tubing and fittings.

In response to the increasing competition and decreasing profitability of textile manufacturers, this product responds to the demands of more efficient and cost-effective production with its main product range called ‘Stars in Automation Technology’. The company develops, manufactures and markets robust standard automation components that ring and compact spinning machines require for challenging operating conditions. Pneumatic cylinders from Festo such as the DSNU (round cylinder), DSBC (ISO cylinder) and ADN (compact cylinder) with the self-adjusting cushioning system PPS have demonstrated their proverbial durability millions of times over, both in the laboratory and in practical operation.

The same applies to the valves VUVS and valve terminals VTUG from Festo. The pneumatic control circuit is completed with the flexible and modular service units of the MS series from Festo as well as suitable tubing and fittings. If a precise approach to positions is required, the solution of choice is the electric cylinder EPCO from the Optimized Motion Series, since it is just as easy to commission as a pneumatic cylinder.

Advance speed in eyelet buttonholes

Buttonholes are not only functional but also have a visual aspect. The automatic eyelet buttonholer 581 from Dürkopp Adler delivers the necessary speed. Thanks to the compact Festo solenoid valves VUVG, it takes just under four seconds to create a buttonhole. In the eyelet buttonholer 581, the solenoid valves type VUVG control all pneumatically driven functions. Compact and with high flow rates, solenoid valves VUVG can be integrated not only into new product developments, but also into existing automatic sewing machines.

High level of automation with BionicCobot

Increasing labour costs in the global market create more demand for intelligent automation solutions in textile production. Festo demonstrated the BionicWorkplace with the BionicCobot as a revolutionary solution for the textile industry at ITMA 2019. Equipped with numerous sensors and the required intelligence, this concept study from Festo features the BionicCobot, a pneumatically operated cooperating robot. The BionicCobot generates its motions using air pressure, which also makes it flexible. This enables it to interact directly and safely with people.

Thanks to their natural motion pattern and the flexible pneumatic components used; bionic lightweight robots are ideal for safe collaboration between people and robots. These robots can be used as assistance systems to perform tasks and ease the load on people, particularly for monotonous or hazardous activities. They could represent an inexpensive alternative to classical robot concepts. The latter require a relatively expensive spindle system for each of its seven axes, including motors, spindles, frequency converters and displacement encoders. The BionicCobot can be equipped with various grippers, depending on the application. It is operated intuitively via a specially developed graphic user interface.

Turnkey solutions from Festo for the Internet of Things and Industry 4.0

The software stands out among the comprehensive smart solutions in this field. Examples of these intelligent, comprehensive software solutions are the Handling Guide Online for fast design and ordering of axis systems; the Festo Design Tool 3D online for combining individual components into pneumatic modules; the product key for the clear identification of each component and use as a digital twin; and the app-based products such as the Festo Motion Terminal.

FluidDraw 365 enables designers to build up circuit diagrams more safely and more efficiently; in order to document machines and installations fast and easily conforming to standards.

With the CPX-IoT gateway, Festo is paving the way for a secure cloud solution; which will enable machine and system builders and end customers; to significantly improve their overall equipment effectiveness. The IoT gateway CPX-IOT connects components and modules from the field level; such as the valve terminal CPX/MPA, the energy monitoring module MSE6-E2M or handling systems; to the Festo Cloud via their OPC UA interface. The cloud makes it possible to process and monitor the data; this in turn enables trend analyses to be worked out and early warning systems and automatic notifications; to be set up in the event of incidents. The IoT gateway connects the cloud to a controller and ensures; that the relevant information is communicated in the right format at the right time.

With the IoT gateway CPX-IOT, it is possible to have preconfigured dashboards for each Festo component – with additional customization. The dashboard is viewed in the web browser and includes diagrams and traffic lights.

VTEM combines digital and pneumatic

The Festo Motion Terminal VTEM, one of the first products of the Industry 4.0 era, combines digitalization and pneumatics. Quickly activated software apps are revolutionizing pneumatics by increasing flexibility and energy efficiency, and accelerating production processes. This also leads to many benefits for the construction and the operation of textile machines. The Festo Motion Terminal VTEM catapults pneumatics into the age of Industry 4.0; with apps that can replace over 50 individual components. The new type of function integration – combined with software apps – simplifies the entire value chain; since only one piece of hardware is now required.